Geocells and Geogrids - Fiberglass Geogrid with Bitumen Coating or PVC Coating

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid With CE ISO certification

Intriduction of Fiberglass Geogrid:

CMAZ fiberglass georid is based on fiberglass woven cloth with modified bitumen or PVC, it was developed to address the problem of pavement cracing on highways, roads and runways, driven by a need to reduce cost for infrastructure maintanance and repair.

It is a characterized by high tensile strength in axial and lateral direcions,low stretch rate, alkali-resistance, low temperature-resistance, as well as convenience in construction and low price. It can be on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs,harbors,ports,water channels,seawalls,etc.

Advantages of Fiberglass Geogrid:

It is characterized by high tensile strength in axial and lateral directions low stretch rate, alkaili-resistance, low temperature-assistance as well as convenience in construcion and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Applications of Fiberglass Geogrid:

1. It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2. it used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction;

3. it is used in road expansion and improvement project and crack caused by old and new combination position and uneven sedimentation;

4. it is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base;

5. it is used for preventing contraction crack caused by new road semi-rigid base layer, and reinforcing and preventing road surface crack caused by foundation crack reflection

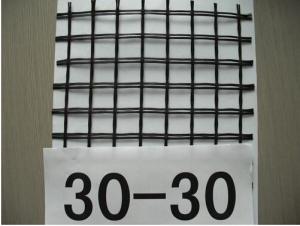

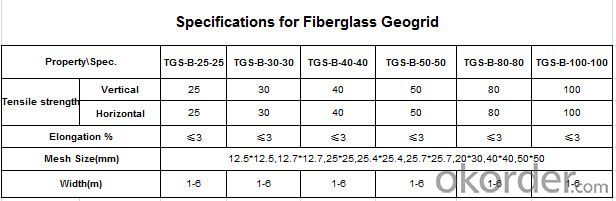

Specifications of Fiberglass Geogrid:

FAQ:

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

Photos of Fiberglass Geogrid and Factory:

- Q: How much is the geogrid return

- Generally speaking, the 10-15cm should be judged according to the specification

- Q: Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Different specifications and models can not compare the price, generally speaking, the same specifications, more expensive than glass fiber

- Q: How do geogrids improve the load transfer in road pavements?

- Geogrids improve the load transfer in road pavements by providing reinforcement and stabilization to the layers of the pavement structure. They distribute and transfer the load from the surface to the underlying layers, reducing the stresses and preventing the formation of cracks and deformations. Geogrids also enhance the interlock between the different pavement layers, increasing the overall strength and load-bearing capacity of the road.

- Q: Can geogrids be used in reinforcement of railway ballasts?

- Yes, geogrids can be used in the reinforcement of railway ballasts. Geogrids are commonly used in civil engineering projects to improve the stability and strength of soil, including railway ballasts. By placing geogrids within the ballast layer, they help distribute the load more evenly, reducing settlement and increasing the overall bearing capacity. This reinforcement technique can lead to improved track stability, reduced track maintenance, and enhanced performance of the railway system.

- Q: Who has the "highway geosynthetics geogrid" specification

- The first part of Geogrid

- Q: Can geogrids be used in green wall systems?

- Yes, geogrids can be used in green wall systems. Geogrids provide structural reinforcement and stability to the soil, which is essential for supporting the weight of the green wall. They help prevent soil erosion, improve drainage, and increase the overall strength of the system, making them a suitable choice for incorporating into green wall installations.

- Q: What kind of material is the geogrid in the quota

- PVC and other high polymer thermoplastic or molded into a two-dimensional grid

- Q: I asked what the raw materials needed for the production were, for example, what the green mesh was made of

- Building safety net, also can be called the steel plastic geogrid. Steel grating and construction safety net (protective net) welded together

- Q: What are the specifications of the geogrid

- Four kinds of glass fiber geogrid and polyester warp knitted polyester geogrid.

- Q: How to distinguish the vertical and horizontal geogrid

- Because the normal use of the vertical and horizontal is the same

Send your message to us

Geocells and Geogrids - Fiberglass Geogrid with Bitumen Coating or PVC Coating

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords