Geocells and Geogrids - High Quality Bitumen Coated Black Fiberglass Geogrid (30KN*30KN-200KN*120KN) for Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

1.Introduction of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

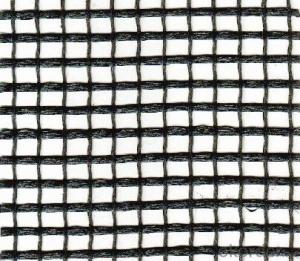

Fiberglass geogrid is a kind of plane network shape material that selects excellent reinforcement non-alkali fiberglass yarn. It is weaven into base material by using foreign advanced warp knitter and adopts warp knitted directional structure. It makes full use of yarn strength in textile, improves its chemical performance and makes it have good tention resistance, tearing resistance and creep resistance and is formed by excellent modified asphalt coating treatment. It follows similar and compatible principle, lays stress on its synthetic performance with asphalt mixture, protects glass fiber base material fully and improve wearing resistance and shearing force resistance of base material so as to make road surface reinforce, to prevent highway harm such as crack and rut from occuring and to solve the problem that asphalt road surface is difficult for reinforcement.

2.Properties of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

The product has high intensity, low elongation ratio, thermostable, high module, light weight, good toughness, anticorrosive, long life and so on characteristics.

It can be applied in the old cement road surface, runway’s service, the dike, the river bank, the side protection, project domains and so on road bridge connection surface enhancement processing.

It can reinforce the road surface and prevents the road surface rut fatigue cracking the hot-cold expansion crack and the following reflection crack.

It can scatter the road surface bearing stress, extense road surface service life, the high tensile strength and the low elongation ratio, no long-term slow change. The physical chemistry stability are good anti-weary dehiscence, antilow temperature shrinkage crack and postpone reduction reflection crack.

3.Specification and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

The parameters of fiberglass geogrid | |||||||

classification | Model number | Break Intensity (KN/m) | Break elongation ratio (%) | Mesh size (mm×mm) | Breadth (m) | ||

longitudinal | horizontal | longitudinal | horizontal | ||||

Fiberglass geogrid | GG2525 | ≥25 | ≥25 | ≤3 | ≤3 | 12~50 | 1~6 |

GG3030 | ≥30 | ≥30 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG4040 | ≥40 | ≥40 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG5050 | ≥50 | ≥50 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG8080 | ≥80 | ≥80 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG100100 | ≥100 | ≥100 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG120120 | ≥120 | ≥120 | ≤3 | ≤3 | 12~50 | 1~6 | |

Self—adhesive fiberglass geogrid | GGA2525 | ≥25 | ≥25 | ≤3 | ≤3 | 12~50 | 1~6 |

GGA3030 | ≥30 | ≥30 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA4040 | ≥40 | ≥40 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA5050 | ≥50 | ≥50 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA8080 | ≥80 | ≥80 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA100100 | ≥100 | ≥100 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA120120 | ≥120 | ≥120 | ≤3 | ≤3 | 12~50 | ||

4.Application and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

Reinforcement for road pavement

Reinforcement for railway basement

Reinforcement for tunnel

Reinforcement for slope

Reinforcement for embankment

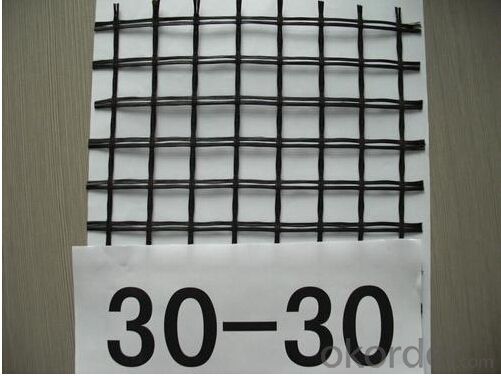

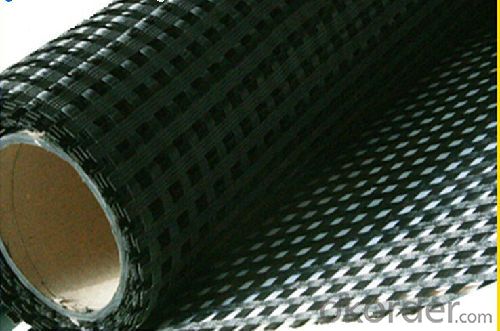

5.Product Photos and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

- Q: Can geogrids be used in mining tailings containment?

- Yes, geogrids can be used in mining tailings containment. Geogrids are often used in mining operations to reinforce and stabilize containment structures, such as tailings dams, due to their high tensile strength and ability to distribute loads. They help prevent slope failures and erosion, improving the overall stability and longevity of tailings containment systems.

- Q: Can geogrids be used in pipeline construction?

- Yes, geogrids can be used in pipeline construction. Geogrids are commonly used as reinforcement materials in soil stabilization and can provide additional support and strength to the pipeline bedding. They help to minimize soil movement and settlement, increase load-bearing capacity, and enhance overall stability of the pipeline system.

- Q: Can geogrids be used in mining tailings management applications?

- Yes, geogrids can be used in mining tailings management applications. Geogrids are commonly employed to reinforce and stabilize soil structures, including mining tailings. They can help in preventing soil erosion, providing stability to the tailings dam, and improving overall tailings management.

- Q: What kind of experiments need to be done to check geogrid

- Or the same as the first inspection, different places are not the same as the results of some of the equipment testing may be out, but the probability is not. The company specializes in the production of Geogrid

- Q: Technical specifications of glass fiber grating

- (kN/m) by 30506580506580 to 30506580506580 weft elongation (%) = 3 = 3 = 3 = 3 = 3 = 3 = 3 mesh size (mm*mm) 25.4 x 25.4 x 25.4 x 25.4 x 25.4 25.4 25.4 25.4 12.7 12.7 12.7 x 12.7 x 12.7 x 12.7 elastic modulus (Gpa) 67676767676767

- Q: Tgsg5050 what is the difference between Geogrid and gsz5050?

- 30-30 "means: per meter of longitudinal and transverse tensile force is greater than the yield of 30KN/m. can be said to be the same.

- Q: Can geogrids be used in soil erosion control for agriculture?

- Yes, geogrids can be used in soil erosion control for agriculture. Geogrids are commonly used to reinforce soil and prevent erosion by stabilizing the soil structure. They can be installed in agricultural fields to enhance the integrity of the soil, reduce surface runoff, and retain moisture, thereby minimizing soil erosion and promoting better crop growth.

- Q: Which is better than geotextile and geogrid

- Geotextile is mainly used in water conservancy for anti reflection

- Q: Can geogrids be used in temporary construction projects?

- Yes, geogrids can be used in temporary construction projects. Geogrids are commonly used to reinforce and stabilize soil in various construction applications, including temporary structures such as access roads, parking lots, and foundations. They provide strength and stability to the soil, preventing erosion and maintaining the integrity of the temporary construction project.

- Q: Can geogrids be used in geothermal energy systems?

- Yes, geogrids can be used in geothermal energy systems. Geogrids are commonly used in geothermal installations to reinforce the ground and provide stability for underground piping systems. They help distribute the weight and thermal load, reducing the risk of ground settlement and ensuring efficient heat transfer.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geocells and Geogrids - High Quality Bitumen Coated Black Fiberglass Geogrid (30KN*30KN-200KN*120KN) for Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords