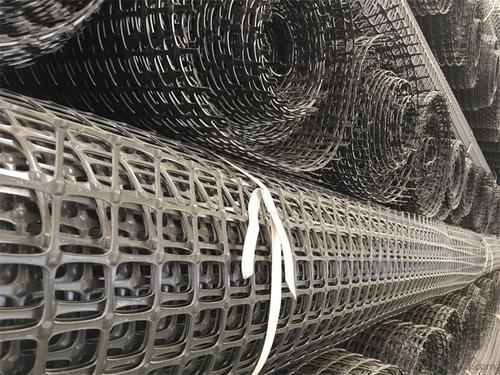

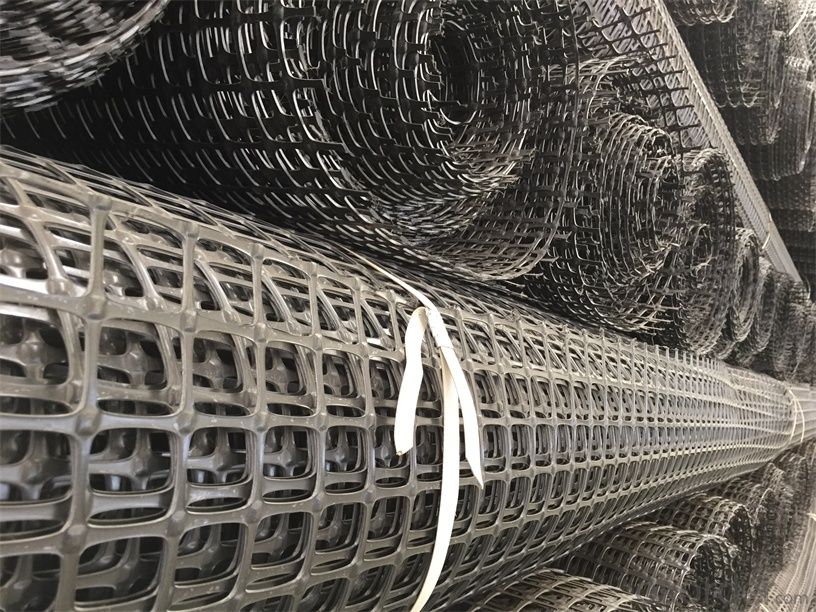

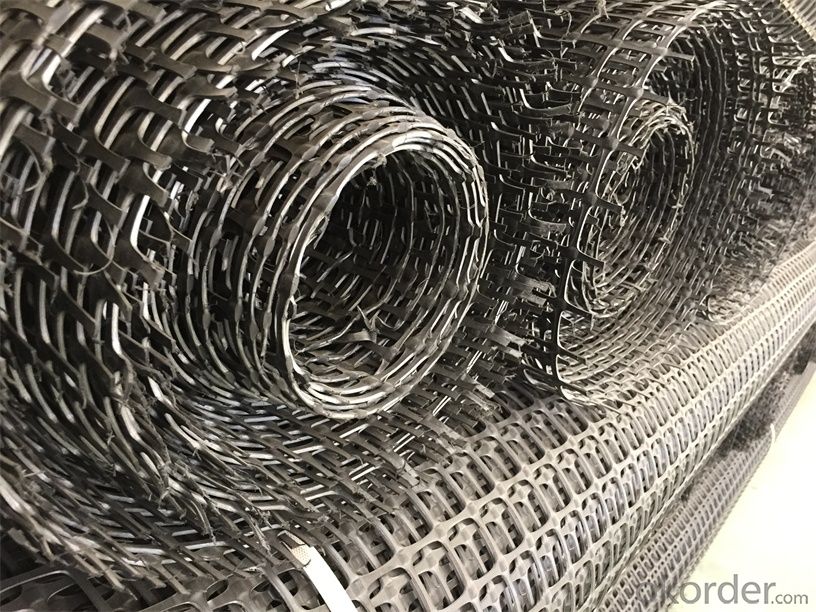

Vegetated Geogrids - Bitumen Coated Fiberglass Geogrid with High Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: What are the factors that affect the installation quality of geogrids?

- The factors that affect the installation quality of geogrids include the type and quality of the geogrid material, proper surface preparation, adequate compaction, appropriate tensioning and anchoring, proper overlap and seam construction, and adherence to manufacturer's guidelines and specifications. Additionally, factors such as weather conditions, soil type, and site-specific requirements can also impact the overall installation quality of geogrids.

- Q: Are geogrids resistant to acid degradation?

- Yes, geogrids are generally resistant to acid degradation. They are commonly made from materials such as polypropylene or polyester which have excellent resistance to acidic environments. This resistance allows geogrids to maintain their structural integrity and performance even when exposed to acidic conditions.

- Q: How to read geogrid grilleBe careful not to copy the dictionary. I want to know why he read it hereI look at the dictionary said: the gate of zhBlock made of bamboo, iron bars, etc.. barsIs it because geogrid can also be seen as a strip of things, so read Zha

- Normal should read Zha, but because of the dialect or engineering terminology habits, read Shan, habit, this is just a personal idea.

- Q: Are geogrids suitable for use in soft soil conditions?

- Yes, geogrids are suitable for use in soft soil conditions. Geogrids are engineered materials that provide reinforcement and stabilization to soils. They are specifically designed to improve the strength and stability of weak or soft soils. By distributing the loads and reducing soil movement, geogrids can effectively enhance the performance of the soil, making them a suitable solution for soft soil conditions.

- Q: What are the technical parameters and testing standards of the tensile creep testing machine

- Tensile creep testing machine for the determination of tensile creep and tensile fracture properties of Geotextiles and geotextile.

- Q: Do geogrids provide reinforcement to geosynthetic liners?

- Yes, geogrids can provide reinforcement to geosynthetic liners. Geogrids are typically used in geosynthetic liner systems to enhance the overall strength, stability, and performance of the liners. They help distribute loads, reduce deformation, and improve the long-term performance of geosynthetic liners.

- Q: Geocell of earthwork grid construction method

- What is geocellGeocell is a kind of three-dimensional grid lattice structure geocell, which is made of HDPE material, which is welded by high strength.What are the characteristics of geocell1, with flexible, transport may be collapsed, the construction can be a Lacheng mesh, fill soil, gravel, concrete and other loose material, which has the structure of strong lateral limit and rigid body.2, light material, wear resistance, chemical stability, light oxygen aging, acid and alkali resistance, suitable for different soil and desert soil conditions.3, the higher lateral restrictions and non slip, anti deformation, effectively enhance the bearing capacity of the subgrade and scattered load.4, to change the height of geocell, welding distance and other geometric dimensions to meet the needs of different projects.5, flexible and easy to transport small size, convenient connection, construction speed.

- Q: What are the design considerations for geogrid installation?

- Some key design considerations for geogrid installation include selecting the appropriate geogrid material and type based on the specific project requirements, considering the soil and subgrade conditions to ensure proper installation and performance, determining the appropriate geogrid placement and orientation to maximize stability and load distribution, and ensuring proper connection and anchoring of the geogrid to adjacent structures or soil to prevent movement. Additionally, factors such as site preparation, construction techniques, and long-term maintenance should also be taken into account during the design process.

- Q: Glass fiber mesh cloth is mainly used in what place

- Reinforced cement products (such as Rome column, flue, etc.) Danyang BOSCH Molding Co., Ltd.. 3) granite, mosaic dedicated network, marble back affixed to the network

- Q: High strength geogrid reinforced cloth, steel plastic grille, PET polyester grille, PP welded geogrid, steel plastic composite tensile band, where are these geosynthetics produced?

- Geogrid is a kind of main geosynthetics, compared with other geosynthetics,

Send your message to us

Vegetated Geogrids - Bitumen Coated Fiberglass Geogrid with High Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords