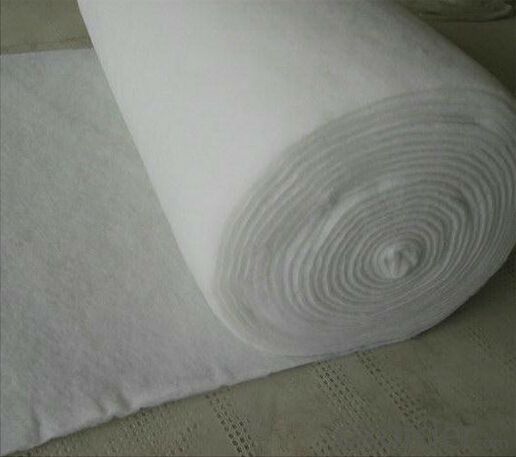

High-Density Polyethylene Geogrids Geotextile Mat Nutrition Geotextile with Grass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nutrition geotextile in water environmental engineering .

Specification:

Geotextile mat,nutrition geotextile,geotextile with grass

Product Feature:

1. Simple and fast construction

2. Achieve the greening effect quickly after construction

3. Due to the grass and composite fiber fabrics become into one integration, so it has the ability of certain degree of flow resistance for the water rising before the grass survive.

4. Composite fiber fabric is a continuous structure from slope top to slope toe, both ends are fixed, has high water flow resistance.

Technical Specification

5.0 m length and 1.05 m width. Reverse side all used filter material. Grass seeds: Bermuda grass (warm season grass), Bahia grass (warm season grass), Kentucky bluegrass (cold season grass), Tall fescue grass (cold season grass), Red fescue grass (cold season grass). Plant height: 0.1 ~ 0.5 m.

| NO. | Items | Specification | Notes | |||

| 1 | Total unit area weight g/sq.m | ≥380 | ||||

| 2 | dimension | width m | 1.0~2.0 | |||

| length m | as per user’s request | |||||

| 3 | Composite fiber fabrics | Material | Polyester Fiber | High strength PET | ||

| Unit area weight g/sq.m | ≥160 | |||||

| Mesh dimension mm | 8×8 | |||||

| Extension strengh kn/m | ≥11 | MD & CD | ||||

| 4 | Filtra layer | Material | Polyester non woven geotextile | |||

| Unit area weight g/sq.m | ≥40 | |||||

| 5 | Grass seeds, Fertilizer | Type | According to actual situation choose 3~5 grass seeds | |||

| Plant height m | 0.1~0.3 | |||||

| 6 | Fiber layer | Material | wood pulp cellulose | |||

| Unit areaweight g/sq.m | ≥15 | |||||

| 7 | flow resistance | ≥4 | not allow appear scour, suction and blanket turn-over etc. damage phenomenon | |||

| M/s | ||||||

| 8 | Anti-UV strengh conservation rate % | 65~80 | 3000hrs Continuously exposure 3000hrs | |||

| 9 | Supporting spare parts | ABS fastening nail | Material | ABS Resin | Fixed between two blankets by length direction | |

| Fiber diameter mm | 35 | |||||

| Nail length mm | 325 | |||||

| Lnail | Material | Steel wire (content 10% zinc-aluminium alloy) | Used to fix single blanket | |||

| Fiber diameter mm | 4 | |||||

| Nail length mm | 200 | |||||

| ABS connecting nail | Material | ABS Resin | Used in the slope between the two blankets ( width direction) | |||

| Nail length mm | 38 | |||||

| Connecting fiber | Material | High strength Polypropylene | Used in the slope between the two blankets ( width direction) | |||

| Length mm | Cut as per request | |||||

APPLICATION:

Generally laid on the river channel, slope protection etc. slope revetment projects, to control the water erosion, soil loss, meantime can reach the effect of slope ecological restoration and landscape greening, making river back to natural.

- Q: Fiberglass geogrid is mainly used for old road reconstruction, the main purpose is to reduce reflection

- (1) due to the existence of joints and cracks, the old cement concrete pavement as the base of the overall strength is reduced, and under the action of external forces, the asphalt overlay in the three-dimensional stress state. The vehicle passing adiscontinuous board, because the joints and cracks on both sides of the adjacent plate reflecting cracks of vertical displacement difference, asphalt overlay in the corresponding position of the larger shear stress, the shear stress is the main reason of asphalt pavement reflection cracks produced. Usually referred to as the load type reflective crack.(2) due to the exposure of the pavement in the atmosphere, the asphalt overlay and the old cement concrete face have the shrinkage and the temperature stress. Because of the Old Cement Concrete Pavement Stress in the joints is not continuous, so the asphalt overlay and bear it and the old pavement caused by temperature stress, especially under low temperature in winter, the asphalt overlay at the seams, cracks, because of excessive tensile stress and cracking formation temperature reflection crack.

- Q: Can geogrids be used in mining tailings management applications?

- Yes, geogrids can be used in mining tailings management applications. Geogrids are commonly employed to reinforce and stabilize soil structures, including mining tailings. They can help in preventing soil erosion, providing stability to the tailings dam, and improving overall tailings management.

- Q: Are geogrids resistant to UV degradation?

- Yes, geogrids are generally resistant to UV degradation. They are designed and manufactured to withstand prolonged exposure to sunlight and maintain their strength and durability over time.

- Q: What is the ultimate tensile strength of geogrid?Ask you

- Both the longitudinal and transverse tensile strength of the biaxial geogrid are 30 (kN/m)Warp knitted geogrid has excellent engineering properties: high tensile strength (> 60 kN/m); elongation is small (about 10%)The tensile strength of glass fiber geogrid is very high, and the elongation rate is very low. The tensile strength can reach 100 M. and the elongation at break is about 3%;

- Q: What are the factors that affect the tensile strength of geogrids?

- The factors that affect the tensile strength of geogrids include the polymer type and quality, the manufacturing process, the grid structure and aperture size, the direction of loading, the environmental conditions, and the level of interface friction between the geogrid and the surrounding soil or other materials.

- Q: Geogrid price? Solution!

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: Can geogrids be used in stormwater management?

- Yes, geogrids can be used in stormwater management. Geogrids are commonly used in stormwater management systems to reinforce soil, stabilize slopes, and retain sediment. They provide excellent erosion control and can enhance the overall effectiveness of stormwater management practices.

- Q: Can geogrids be used in wastewater treatment applications?

- Yes, geogrids can be used in wastewater treatment applications. Geogrids are often used in the construction of wastewater treatment facilities to reinforce soil and prevent erosion. They can also be used to stabilize slopes and retain walls, which are common features in wastewater treatment plants. Additionally, geogrids are used to reinforce and separate different layers of soil, ensuring the stability and longevity of the wastewater treatment infrastructure.

- Q: Are geogrids suitable for reinforcing railway subgrades?

- Yes, geogrids are suitable for reinforcing railway subgrades. Geogrids help to improve the stability and load-bearing capacity of the subgrade by distributing the loads more evenly. They also reduce soil movement, improve drainage, and prevent the formation of cracks and settlement. Overall, geogrids can significantly enhance the performance and longevity of railway subgrades.

- Q: Steel wire mesh is a kind of geotechnical material

- The wire grid contact strength (tensile, shear, tensile and torsional) must be high, and better grid vertical ribs contact force transmission performance, the transverse ribs have the force to the longitudinal rib through the contact, and vice versa. Therefore, requirements must contact the overall good contact strength to close rib strength (tensile fracture is not at the junction, or both) intensity should be small, in order to match, this is the most reasonable, the most economical. Otherwise, the contact strength is much lower than the reinforcement strength, cannot play the security capability of the high strength tensile ribs, the formation of structural consequences caused by the "big horse car" type of waste

Send your message to us

High-Density Polyethylene Geogrids Geotextile Mat Nutrition Geotextile with Grass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords