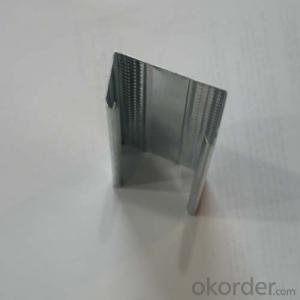

Galvanized Steel Drywall Profiles Ceiling Channels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

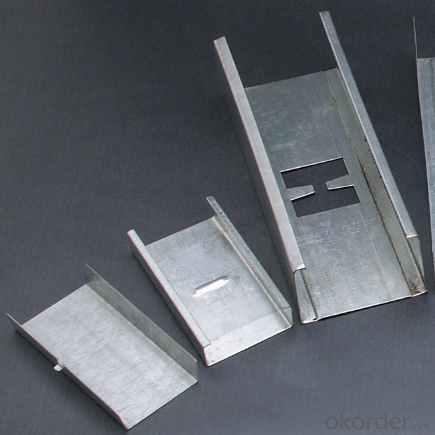

Regular Specification for Partition Wall System

1. Stud size: 50 x 35mm, 50 x 40mm, 70 x 35mm, 70 x 40mm, 75 x 35mm, 75 x 45mm, 100 x 45mm

2. Track size: 50 x 30mm, 70 x 35mm, 75 x 35mm, 75 x 40mm, 100 x 40mm

3. Length: 2. 7mm, 2. 8mm, 2. 9mm, 3. 0mm

4. Thickness: 0. 35mm, 0. 4mm, 0. 45mm, 0. 5mm, 0. 6mm

All sizes and shapes of steel channels are available

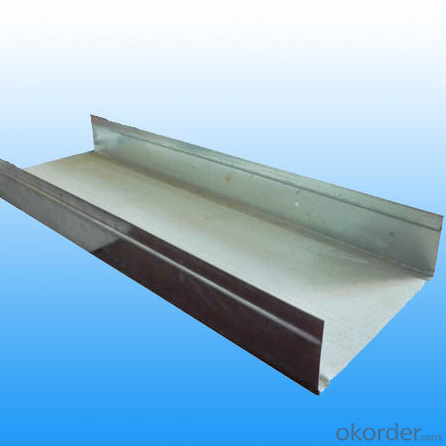

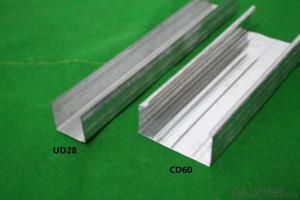

Ceiling Channel for ceiling system

1. Supporting channel: 38 x 12mm, 38 x 20mm, 50 x 15mm, 60X27mm

2. Covering channel: 50 x 19mm, 60x 27mm ,35x22mm

3. Length: 2. 7mm, 2. 8mm, 2. 9mm, 3. 0mm

4. Supporting channel: 0. 5mm, 0. 6mm, 0. 8mm, 1. 0mm, 1. 2mm

5. Covering channel: 0. 35mm, 0. 4mm, 0. 45mm, 0. 5mm, 0. 6mm

All sizes and shapes of steel channels are available

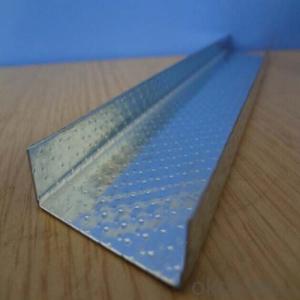

Corner bead & wall angle

U angle 24x19x13x0.4/0.45/0.5mm

L angle 25x25x0.4/0.45/0.5mm

All sizes and shapes of steel channels are available

Advantages

1. Raw material is high quality hot dipped zinc galvanized steel strip, good fireproof and heat insulation, waterproof, antirust, anticorrosive ,and high durability.

2. High quality raw material guarantees the light steel keel of life and good performance of construction.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 3weeks after receiving of downpayment

Picture

- Q: Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Light steel keel wall strength regardless of Zeyang are a heart disease, if there is room, then the proposal is still good wall

- Q: The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- Can only use the exhibition frame. You may be a mall. Now shopping malls are so, independent to be a exhibition,

- Q: 6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- It is best to do the top, or else do the ceiling to do the wall can also be done,

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- The walls of the bathroom must be waterproof and moistureproof, or it will be deformed and affect life. And the bathroom wall to do the waterproof treatment, or the toilet to the area of water and more will then penetrate the other side of the wall.

- Q: How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- If it is looking for decoration workers to do, then they are professional. Under normal circumstances is the use of surge tube and self-tapping screws fixed. (There are other ways). Keel specifications a lot, generally long after the increase in joints. What specifications of the keel with what specifications of the joints. Not common.

- Q: Light steel keel gypsum board wall panels have cracks how to do?

- Repair with glass fiber gypsum

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- My advice is not to do on wooden flooring Because the wood floor is flexible. The The It is best to finish the wall, and then restore the floor Just personal opinion for reference only

- Q: Decorative light steel keel paper gypsum board wall height of 4.1 meters span 6.5 meters need not add structural column, beam

- Do not understand what the title of the 'span' is a special term, the wall is a vertical component, there is no 'span'

- Q: Light steel keel partition wall how to paint

- Personal feel that the painting will not affect the load bearing, as the choice of home painting should be bright, festive and music-based content, a symbol of wealth and wealth of peony painting, a symbol of the lotus and koi map, Healthy longevity of the pine and cypress Evergreen and so are more suitable for home furnishings. And should not hang some unexpected things, such as some works but too aloof, only to the collection, on the home as a decoration is not appropriate.

- Q: What is the difference between gypsum board partitions and lightweight partitions?

- Gypsum board partition and lightweight partition the most important difference there are three points: First, the difference between the structure. Gypsum board is a skeleton-like partition, that is, to rely on the backbone of light steel keel can stand up, and light partition entirely by their own plate to cut off; Second, the difference between materials, gypsum board itself is only gypsum and pulp Composite products, and lightweight partition is made of sheet metal, wood chips, cement foam, additives, perlite composite wall;

Send your message to us

Galvanized Steel Drywall Profiles Ceiling Channels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords