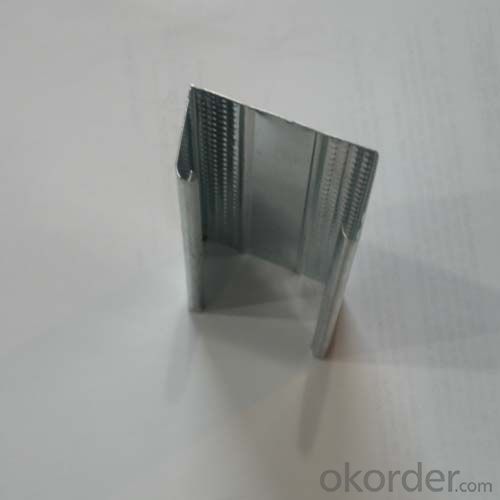

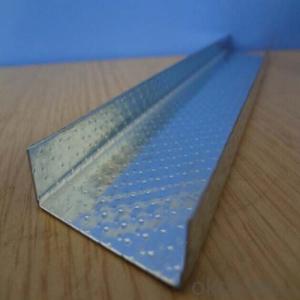

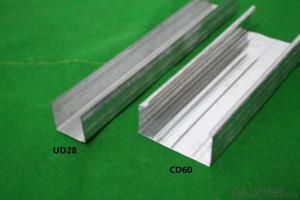

Galvanized Steel Furring Channel Drywall Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall Metal Profile

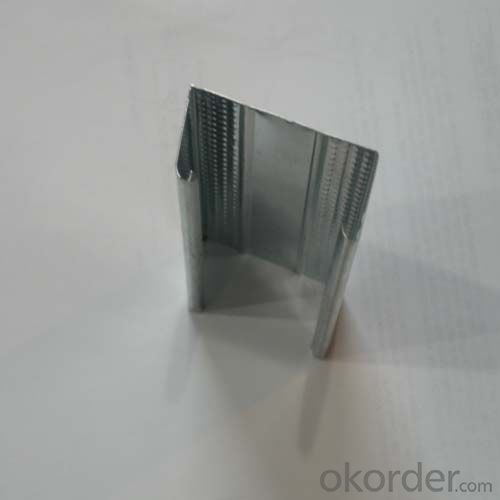

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

HUILON Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with HUILON magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

Product Overviews

- Q: Light steel keel wall to withstand the number of wind load

- Light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, Interior decoration, ceiling and other places.

- Q: Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel life in humid environment Short brick block from the weight of large but because the single volume of small transport more convenient light partition board can be used for humid environment but a single volume upstairs is not convenient to install as light steel keel convenience The cost gap is not big

- Q: Light steel keel gypsum board partition should pay attention to what quality problems

- Bathroom, bath and other multi-water room and high humidity room light steel keel gypsum board wall of the root, the application of C15 concrete to do 120mm high wall base. Gypsum board seams should be used by the manufacturers supporting the supply, dedicated to the joints with the caulking paste and cap joints to ensure that the quality of gypsum board joints.

- Q: Light steel keel wall Why do not cross brace welding with welding

- Then the book is too much trouble to weld, to master the master to welding, Moreover, the time is too long, so no one with the welding.

- Q: Light steel keel wall how much money a square

- Is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, railway stations, Theater, shopping malls, factories, office buildings, old building renovation, interior decoration, roof and other places.

- Q: Curved gypsum board wall technology.

- If the curvature is not large, then the gypsum board can be bent directly over, the deformation of the gypsum board itself is enough, if the curvature is too large, then only cut the stitching, and then patch repair, no matter what method, Do not use anything evenly spray water and then bend into the arc, gypsum board wet water, the intensity is very low, although dry, the strength and good board is not very different, but there may be deformation of the plate

- Q: What is the relationship between the base board and the liner, whether the keel is between the two layers? Such as light in the wall to do soft package, the basic board and liner how to connect?

- In fact, the soft bag is not soft package, sponge package in a 9mm Austrian Song board, this is the soft bag, and then in order to fixed on the wall, in the light steel keel wall to do a lining you said, That is, I mentioned above the blockboard base.

- Q: With light steel keel gypsum board do partition wall price how to count?

- Baoqing about 25, all 100-130 (material pricing).

- Q: How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Effective space division The internal space of the plant is mainly divided by the operator according to their actual use requirements to make reasonable use of space, if the plant has a large number of equipment, it is not appropriate to set too much partition and partition, as far as possible to the ground color or with some Color identification to the division of the region, with the identification of the area to avoid too much color, so not only the regional division is not obvious also feel dizzy, and some plants can be clearly divided into the equipment area and office area, such a plan It is now more common because it is easy to manage. Then in the design of such a plant must master the data and the close combination of space, but also take into account the equipment area and the working area of the work area is smooth and dust, noise interference.

Send your message to us

Galvanized Steel Furring Channel Drywall Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords