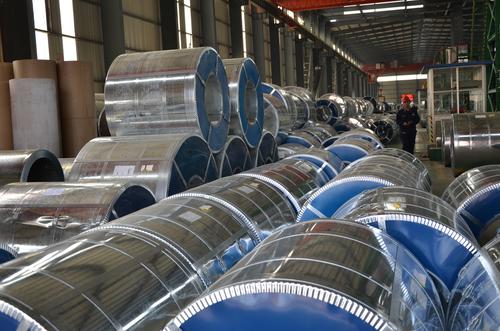

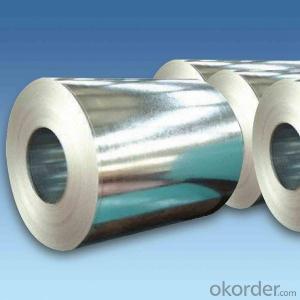

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Quality Standard & Grade: JIS G3302, SGCC / ASTM 653M CQ/ EN10142 DX51D+Z

2) Thikness tolerance: +/-0.02mm Width tolerance:+/0.02mm

3) Zinc coating weight: 50g/m2

4) WEIGHT OF PER COIL: 3-5MT

5)Technology: cold rolled

6) Surface of Product: regular spangle / big spangle/ small spangle; Surface Treatment: chromated , non oiled, skin passed

7) Packing: export standard packing,packed with moisture resistant paper and metal

wrapping,securely tied for export,on metal skids7) Country of Origin :

SIZE:0.15*750

- Q: Having a greater amount than 2% carbon in steel causes steel to suddenly become brittle. Why is this?

- Carbon fiber has better tensile capability then steel meaning its better while pulled aside. Plus you could mould the fiber to make autos-or homes-out of carbon fiber.

- Q: What are the challenges in coil slitting for narrow strip widths?

- There are several challenges associated with coil slitting for narrow strip widths. One of the main challenges is maintaining accuracy and precision during the slitting process. When dealing with narrow strip widths, even the slightest misalignment or deviation can result in significant defects or inconsistencies in the final product. This requires careful calibration and adjustment of the slitting equipment to ensure that the strips are cut with utmost accuracy. Another challenge is the risk of material damage or deformation during the slitting process. Narrow strip widths are more prone to distortion, wrinkling, or edge cracking, especially if the material is not properly handled or supported during slitting. Special care must be taken to ensure that the material is fed smoothly through the slitting machine and that the tension is properly controlled to minimize any potential damage. Additionally, narrow strip widths can pose challenges in terms of handling and transporting the slit coils. These coils are more susceptible to bending, twisting, or telescoping, which can lead to difficulties in stacking, storage, or transportation. Proper packaging and handling techniques must be employed to ensure that the slit coils maintain their shape and integrity throughout the supply chain. Furthermore, narrow strip widths often require more frequent blade changes during the slitting process. This increases the complexity and time required for setup and maintenance, as the blades need to be carefully selected and replaced to achieve optimal cutting results. It is crucial to have skilled technicians who can handle these blade changes efficiently and effectively. Overall, while coil slitting for narrow strip widths offers various benefits such as cost savings and increased material utilization, it also presents several challenges that need to be carefully addressed. These challenges include maintaining accuracy, preventing material damage, ensuring proper handling and transportation, and managing blade changes effectively. By understanding and addressing these challenges, manufacturers can optimize their coil slitting operations and produce high-quality narrow strip products.

- Q: How do steel coils contribute to the agricultural sector?

- Steel coils contribute to the agricultural sector in various ways. Firstly, steel coils are used in the manufacturing of agricultural machinery and equipment such as tractors, harvesters, and irrigation systems. These machines are essential for efficient farming operations, helping farmers increase productivity and reduce labor costs. The strength and durability of steel coils ensure that the machinery can withstand the harsh conditions of the agricultural environment. Additionally, steel coils are used in the construction of storage facilities and warehouses for storing agricultural products. These structures need to be strong and resistant to external elements to protect the crops from damage. Steel coils provide the necessary strength and stability required for constructing these storage facilities, ensuring the safe storage of agricultural produce. Furthermore, steel coils are used in the fabrication of fencing and other agricultural infrastructure. Fencing is crucial in protecting crops from animals and preventing trespassing. Steel coils provide a robust material for fencing, ensuring the security and protection of agricultural lands. Moreover, steel coils are utilized in the production of irrigation pipes and systems. Efficient irrigation is vital for the growth and yield of crops, especially in areas with limited water resources. Steel coils are used to manufacture pipes that can withstand high pressure and are resistant to corrosion, ensuring the efficient distribution of water throughout the agricultural fields. In summary, steel coils play a significant role in the agricultural sector by providing the necessary materials for manufacturing machinery, constructing storage facilities, fencing, and irrigation systems. The strength, durability, and resistance to harsh conditions make steel coils an essential component in enhancing agricultural productivity, protecting crops, and ensuring efficient farming practices.

- Q: Im in the process of replacing the gutters/down spouts on my house. The top of the house is four sided. The bottom level has a porch area with 3 sides, two smaller roofs in the back, and one small roof on the side with all stainless steel gutters. A two story house. Not sure of the demensions. They were made at a Steel Mill where the previous owner, worked.This guy wants to buy the stainless gutters but I need to know the market value of this steel and offer him a price. Can someone tell me what I can sell it for? Does it go by the pound? Foot? Can you give me an idea please? Theres a lot of it! I have no clue what to do! Thanks!

- Depends on the company but you'd probably get a decent amount of money. Try searching different sites.

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes include scratches, pits, roll marks, stains, and unevenness. These defects can be caused by various factors such as improper handling, processing issues, or equipment malfunction. These surface defects affect the aesthetics and quality of the steel coil, making it unsuitable for certain applications or requiring additional processing to rectify the defects.

- Q: My musical saw has, despite my best efforts, got little patches of rust on it. How Do I go about removing the rust without spending too much on rust-removal products and without affecting the properties of the steel?

- Steel wool and a bit of WD 40. Steel wool will remove the rust and the WD 40 will protect it in the future.

- Q: How do steel coils contribute to the aerospace manufacturing industry?

- The aerospace manufacturing industry heavily relies on steel coils due to their numerous benefits and contributions to overall aircraft production efficiency and quality. To begin with, steel coils are essential in fabricating various structural components of an aircraft, including wings, fuselage, and landing gear. Steel's high strength and durability make it an appropriate material for these critical parts, guaranteeing aircraft safety and reliability. Moreover, steel coils provide the raw material necessary for the precise manufacturing processes required in the aerospace industry, enabling the creation of lightweight yet sturdy structures capable of withstanding the demanding flight conditions. Apart from their structural applications, steel coils also find use in producing smaller aircraft components, such as fasteners, connectors, and brackets that hold different parts of the aircraft together. Steel's exceptional mechanical properties, including resistance to fatigue and corrosion, make it a preferred choice for these components, ensuring their long-term performance and safety. Furthermore, steel coils contribute to the aerospace manufacturing industry by facilitating cost-effective production processes. Steel is widely available in large quantities, making it a cost-efficient material for aircraft manufacturing. Additionally, the ability to produce steel coils in various sizes and thicknesses allows manufacturers to tailor their production to specific aircraft models or design requirements, minimizing waste and optimizing resource allocation. Moreover, steel coils offer inherent recyclability, which aligns with the aerospace industry's increasing focus on sustainability. Recycled steel can be used to produce new coils, reducing the need for raw material extraction and minimizing environmental impact. This circularity in the use of steel coils supports the aerospace industry's efforts towards a more sustainable and environmentally friendly manufacturing process. In conclusion, steel coils play a vital role in the aerospace manufacturing industry by providing the necessary materials for aircraft structures and components. Their strength, durability, cost-effectiveness, and recyclability make them a valuable resource, ensuring the safety, reliability, efficiency, and sustainability of aircraft production.

- Q: How are steel coils processed for different levels of hardness?

- Steel coils can be processed to achieve different levels of hardness through a variety of methods. One common method is heat treatment, which involves heating the coils to a specific temperature and then rapidly cooling them to alter their microstructure and achieve the desired hardness. The process of heat treatment can include quenching, tempering, or annealing, depending on the desired hardness level. Quenching involves cooling the coils rapidly in a liquid medium such as water or oil to achieve a high hardness level. Tempering, on the other hand, involves reheating the coils to a lower temperature and then slowly cooling them to achieve a desired balance of hardness and toughness. Annealing is a process that involves heating the coils to a specific temperature and then slowly cooling them to relieve internal stresses and achieve a softer and more ductile material. Additionally, mechanical processes such as cold rolling or cold working can also be used to increase the hardness of steel coils. These processes involve subjecting the coils to compressive forces, which cause the material to deform and result in an increase in hardness. Overall, the processing of steel coils for different levels of hardness requires careful control of temperature, cooling rate, and mechanical forces to achieve the desired properties for specific applications.

- Q: What are the common coil inspection techniques?

- Some common coil inspection techniques include visual inspection, magnetic particle inspection, eddy current testing, and ultrasonic testing.

- Q: What are the different types of steel coil edge conditions?

- The different types of steel coil edge conditions include mill edge, slit edge, and deburred edge.

Send your message to us

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords