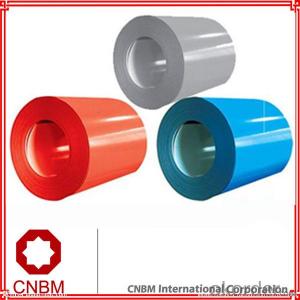

Prepainted Galvanized Steel Coils of Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:CGCC, JIS3312

Surface Treatment:Coated

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, JIS, GB

Application:Construction, Roofing and So on

Edge:Slit edge

Stock:Stock

Steel Grade:Q195-235

Thickness:0.16-0.8mm

Width:800-1250mm

Color:Ral Number

Zinc:30G/M2-100G/M2

Coils Weight:3-5tons/Coils

Export Markets:Global

Prepainted galvanized steel coils

1. PPGI, prepainted galvanized steel coil(Annual Output: 200, 000tons)

(1). Leading manufacturer in China

(2). Competitive price

(3). High quality

(4). Good after-sale service

2. The Feature of PPGI:

1). Geade: CGCC, other grade can be available

2). The thickness range of the PPGI: 0.16mm to 0.8mm

Tolerance of thickness of The PPGI: +/-0.03mm

3). Width range: 800mm to 1250mm

Tolerance of width: +/-3.00mm (aiming to +/-2.00mm)

4). Zinc coating: Z40-Z275

5). Coil internal diameter: 508mm

6). Packing: Standard waterproof paper and galvanized steel protection cover and steel strip packed

7). Applications of PPGI: Widely used for roofs, outer walls, ovens, Explosive-proof steel, electrically controlled cabinets, and industrial freezers in the Residential and industrial buildings.

The detailed information:

Price termsFOB, CFR, CIF

Payment terms30%TT in advance+70% TT or irrevocable 70%L/C at sight

Delivery time25 days after recepit of 30% TT

RemarksInsurance is all risks

MTC will be handed on with shipping documents

- Q: How are steel coils used in the production of metal partitions?

- The production of metal partitions relies heavily on steel coils, which are a vital ingredient. These coils, typically made from top-notch steel, act as the primary material for manufacturing the partitions. To begin with, the steel coils undergo a process called slitting, where they are sliced into narrower strips of the desired width. This step allows manufacturers to tailor the size of the metal partitions according to specific project requirements. Following slitting, the steel strips are fed into a roll forming machine. This machine gradually transforms the strips into the desired profile for the metal partitions. The roll forming process involves passing the steel strips through a series of rollers, which progressively bend and shape the metal into the desired form and dimensions. Once the metal has been shaped as desired, it is then cut into appropriate lengths to create individual partitions. These partitions undergo further processing, such as welding or spot welding, to join different components and enhance their structural integrity. Steel coils are highly preferred for metal partition production due to their strength, durability, and versatility. The use of steel ensures that the partitions can withstand heavy loads, resist corrosion, and offer long-lasting performance. Moreover, steel coils provide a high degree of design flexibility, allowing for the creation of various partition styles, including solid panels, perforated screens, or mesh partitions. All in all, steel coils play a pivotal role in the production of metal partitions by providing the necessary raw material, strength, and customization options required for these adaptable architectural elements.

- Q: We just installed a stainless steel electric stove, what is the best way to keep it clean and shiney?

- I have a combo of black and stainless in my kitchen; not sure which one is worse some days. For normal everyday stuff, hot, soapy (Dawn), clean dishwater and a microfiber cloth work great. For quick touch ups, a 50/50 mixture of window cleaner and rubbing alcohol also works great. The window cleaner gets the grease and the alcohol helps with streaks and makes the cleaner germ killing. Use with a microfiber cloth. For really nasty burned on stuff, I'd use a sponge with a non-stick cookware safe nylon scrub pad on it and some of the hot, soapy water. Just lay the damp sponge on the spot, let it soak a bit and see if it comes off. If not, try a little Barkeeper's Friend. Dampen, sprinkle, smear it around a little and let it soak for about 10 minutes. Then scrub with the sponge. Wipe up the residue with the microfiber cloth. The microfiber cloths are really key; they wipe more efficiently than any sponge, wipe, paper towel, dish rag. Get several and change them out frequently. You just wash and dry them; no fabric softener and you're ready to use them again. And it wouldn't hurt to keep a protective coat of a good stainless steel product on there either. That helps keep the stuff from getting such a good hold. But I've found that most of those are pretty bad at cleaning; so clean it first, then polish.

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These techniques help identify surface cracks, internal flaws, irregularities in thickness, and other defects, ensuring the quality and integrity of the steel coils.

- Q: What is the typical weight of a steel coil?

- The typical weight of a steel coil varies widely depending on its size, thickness, and type of steel used. However, a common range for steel coils is between 3 to 25 metric tons.

- Q: What is current price of steel in US market?

- here okorder /

- Q: How are steel coils used in the production of steel drums?

- Steel coils are used in the production of steel drums by being cut into sheets and then rolled into cylindrical shapes, which form the body of the drum. The coils provide the necessary strength and durability required for the drums to hold and transport various materials safely.

- Q: How are steel coils tested for tensile strength?

- Steel coils are tested for tensile strength through a process called tensile testing. In this method, a small sample is taken from the steel coil and subjected to a controlled force until it breaks. The force applied during the test is gradually increased until the sample fractures. The maximum force required to break the sample is measured, and this provides valuable information about the tensile strength of the steel coil.

- Q: What are the common coil surface treatments available for steel coils?

- The common coil surface treatments available for steel coils include galvanizing, galvannealing, electro-galvanizing, and painting.

- Q: What are the different grades of steel used for manufacturing coils?

- Manufacturing coils requires the use of various grades of steel, each selected for their specific properties and suitability for different purposes. Some commonly used grades include low carbon steel, high carbon steel, stainless steel, galvanized steel, and alloy steel. Low carbon steel, also known as mild steel, is a cost-effective option with good formability. It is ideal for applications that require low strength and high ductility, such as automotive components and construction materials. High carbon steel is characterized by its exceptional strength and hardness. It is commonly employed in the production of coils that demand high tensile strength, like springs and wires. Stainless steel, an alloy with a high chromium content, offers corrosion and oxidation resistance. It is often utilized in the manufacturing of coils for the food industry, medical equipment, and automotive applications. Galvanized steel, on the other hand, is steel coated with a layer of zinc to safeguard it against corrosion. It is frequently used in the production of coils that will be exposed to harsh environmental conditions or require excellent durability, such as roofing materials and electrical appliances. Alloy steel, formed by adding elements like manganese, nickel, chromium, or molybdenum to carbon steel, exhibits improved strength, hardness, and resistance to wear and corrosion. It finds wide application in industries that necessitate high strength and toughness, such as aerospace and automotive. Choosing the appropriate grade of steel is crucial to ensure optimal performance and longevity of the coils, as it is essential to match the specific requirements of the application.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

Send your message to us

Prepainted Galvanized Steel Coils of Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords