Galvanized Steel Coils Sheet Zero Spangle l HDGI Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Features of this kind pre-painted coil:

1)base steel can be galvanized steel coil

2)the combining force between the base steel and the paint is very strong

3)color:white,black,sky blue.bright red,yellow,RAl standard

4)color fabric:two coats for top,single coat for bottom

5)can be used in building material field,galvanized wire steel tape ,roofing and other field.

6)packing:for export standard or as customers' requestment

2.Usages of this kind pre-painted coil:

Galvanized sheet is mainly used in architecture, light industry, automobile, agriculture,animal husbandry,fishery, and commerce, etc.

1).In architecture industry ,to manufacture roof panel and roof grate of anti-corrosive industrial and civil building,

2). In light industry, to make shell of household electrical appliance, chimney for civil use, kitchenware,etc,

3). In automobile industry, to make anti-corrosive parts of car,

4).To make freezing processing tools for grain storage & transport, meat, and sea food;

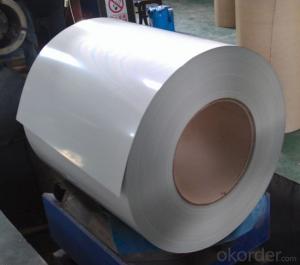

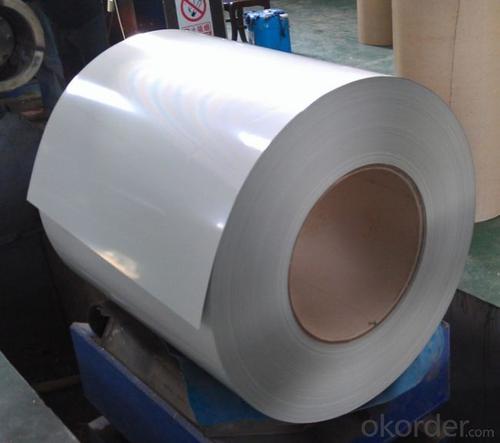

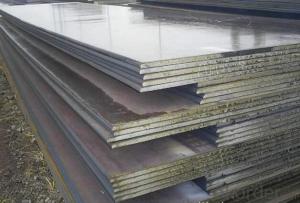

3.Prepainted Galvanized Steel Images:

4.Galvanized Steel Specification:

Name | Galvanized steel coil/sheet |

Grade | SGCC, SGCH, DX51D |

Place of Origin | China (Mainland) |

Brand Name | GH |

MOQ | 25MT, 20 feet container |

Payment | T/T 30% in advance, rest receiving against B/L |

Delivery Time | 15--30 days after receive your advanced payment |

Reel | 3-8 Tons |

Thickness | 0.23--1.2mm |

Width | 600-1250mm |

Width Tolerance | +/- 0.02mm |

Zinc coating | 60-80-100-120-270-290 g/m2 |

Color | bright silver |

Sample | provided free |

Length | according to your requirement |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | SGCC,DC51D,DX51D,DX52D,SPCC,SGCD,Q195,Q235,SGHC |

Surface treatment | chromate, oil/unoil, bright finish, spangle, anti-finger print |

5.Our Factory:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the width range of steel coils?

- The width range of steel coils can vary depending on the specific type and purpose of the coil, but it typically falls within the range of 600 mm (23.6 inches) to 2,200 mm (86.6 inches).

- Q: How are steel coils used in the manufacturing of agricultural implements?

- Steel coils are used in the manufacturing of agricultural implements as they are shaped and formed into various components such as blades, tines, and frames. These components are then assembled to create durable and reliable equipment that is used for tilling, planting, harvesting, and other farming activities. The strength and versatility of steel coils make them ideal for creating robust and long-lasting agricultural implements.

- Q: Suppose you made a sword out of diamond (just follow me here, it's only theoretical). Would it be lighter than a sword of the same size made out of steel?

- The weight of steel is dependent among what kind of steel, shape, length, width, thickness a 5mm by 5mm ball of carbon steel would wiegh 1.69969 g a same size diamond weighs .79 carats equivelent to 1.5 grams So the basic answer is, yes, diamond is lighter than steel, but barely

- Q: What are the common defects in steel coils?

- Some common defects in steel coils include surface defects like scratches, rust, and pits, as well as internal defects like cracks, laminations, and non-uniform thickness. Other defects may include coil set, which is a curvature in the coil, and edge wave, which is a distortion along the edges of the coil.

- Q: Can steel coils be deep-drawn?

- Yes, steel coils can be deep-drawn. Deep drawing is a metal forming process in which a sheet or coil of material, such as steel, is stretched and pulled into a die to create a deep, hollow shape. Steel coils are often used in industries such as automotive, appliance, and manufacturing, where deep-drawn components are required for various applications.

- Q: What are the common coil thicknesses available for steel coils?

- The common coil thicknesses available for steel coils can vary depending on the specific application and industry requirements. However, some of the most common coil thicknesses for steel coils range from 0.5mm to 3mm. These thicknesses are commonly used in various manufacturing processes, including automotive, construction, and appliance industries. For lightweight applications or where flexibility is required, thinner steel coils with thicknesses ranging from 0.5mm to 1.5mm are often used. These thinner coils are suitable for applications such as automotive body panels, roofing, and general sheet metal fabrication. On the other hand, for applications that require higher strength and durability, thicker steel coils with thicknesses ranging from 1.5mm to 3mm are commonly used. These thicker coils are often utilized in heavy-duty construction, structural components, and industrial equipment manufacturing. It is important to note that these are just general ranges, and specific coil thicknesses can vary depending on the specific requirements of a particular project or customer preference. Steel coil thicknesses can be customized to meet specific needs, allowing for greater flexibility in various industries.

- Q: an 18k steel and gold, screw style bracelet how much would it be worth?

- If you use a Gold Calculator you can find out how much it is worth.

- Q: What are the factors to consider when selecting a supplier for steel coils?

- There are several factors to consider when selecting a supplier for steel coils. 1. Quality: The supplier's reputation for providing high-quality steel coils is crucial. The steel coils should meet industry standards and have consistent quality to ensure the durability and performance of the final product. 2. Reliability: It is important to choose a supplier that can consistently meet your demand for steel coils. They should have a proven track record of on-time delivery and the ability to handle large orders efficiently. 3. Cost: The pricing of steel coils is a significant factor to consider. While it is essential to find a supplier that offers competitive prices, it is equally important to ensure that the quality is not compromised. Comparing prices from multiple suppliers is advisable to find the best balance between cost and quality. 4. Range of Products: Look for a supplier that offers a wide range of steel coil products. This ensures that you have various options to choose from and can find the exact specifications and dimensions that meet your requirements. 5. Technical Expertise: A supplier with technical expertise and experience in the steel industry can provide valuable advice and assistance in selecting the right steel coils for your specific needs. They can also help with any customization or special requirements you may have. 6. Location and Delivery: Consider the supplier's location and their ability to deliver steel coils to your desired location. Choosing a supplier who is geographically closer to your facility can help reduce transportation costs and lead times. 7. Customer Service: A supplier who values good customer service is always preferable. They should be responsive to your inquiries, provide timely updates, and be willing to address any issues or concerns that may arise. By considering these factors, you can make an informed decision and choose a supplier that best meets your requirements for steel coils.

- Q: How are steel coils used in the production of roofing panels?

- Steel coils are used in the production of roofing panels by being fed through a machine that shapes and cuts the steel into the desired panel size and shape. The coils are unrolled and flattened, then passed through a series of rollers to form the corrugated or flat panel profile. This process ensures the panels have the strength and durability required for roofing applications.

- Q: How are steel coils used in the production of fireproof doors?

- Steel coils are used in the production of fireproof doors as they provide the necessary strength and durability to withstand high temperatures and prevent the spread of fire. The coils are formed into sheets or plates, which are then used to construct the framework and core of the fireproof doors. This ensures that the doors can effectively resist fire and protect buildings and occupants from its dangers.

Send your message to us

Galvanized Steel Coils Sheet Zero Spangle l HDGI Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords