Galvanized Steel Sheet Coils in High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

镀锌Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• High strength

• Good formability

• Good visual effect

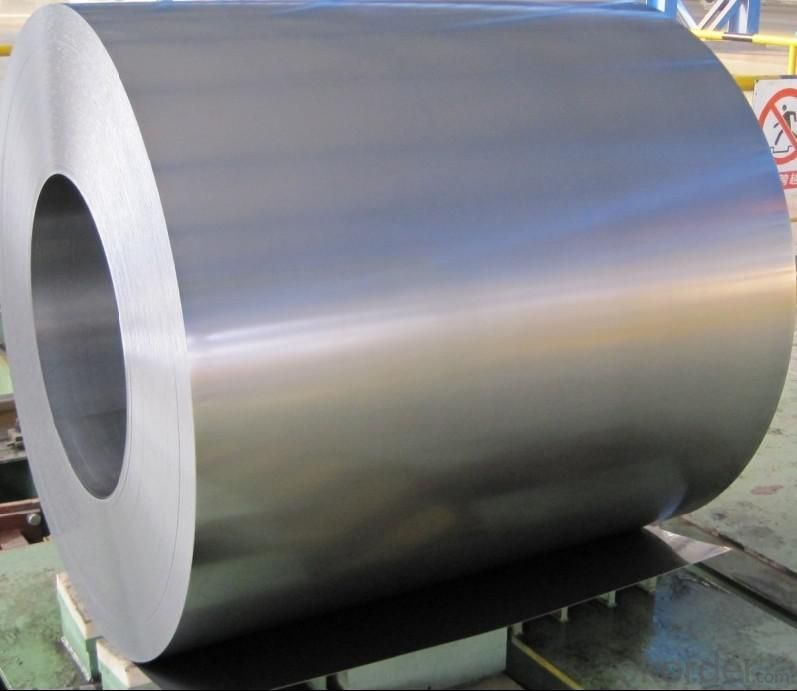

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: So here's the deal:I recently bought McCann's Instant Steel-Cut Oatmeal, and I'm wondering about any possible nutritional differences between the instant and regular stove-top. In case you haven't seen it, instant steel-cut comes in individual packets and is cooked only by adding boiling water, the same as instant rolled oatmeal (i.e. Quaker).When I asked about instant vs. stove-top rolled oats, my doctor said there are no significant nutritional differences, but since the main health appeal of steel-cut is the coarse grain, it doesn't seem possible for the finer ground instant to be as nutritious.I can't find much info about this, so any help is appreciated!

- Most people who are used to rolled oats have a very hard time adjusting to steel cut oats that are cooked only 30 minutes. For many, it's not much different than eating them raw. (Raw, soaked oats is called cram. Having to eat uncooked oats, as only the poorest would do, gives us the expression 'to cram it down your throat'.) Better still is to cook them thoroughly at night then reheat portions for breakfast if you're in a hurry. They'll keep about five days at a time under refrigeration. Any small nutritional loss from longer cooking is more than compensated by the better digestibility of well-cooked oats. That is, the nutrition is wasted if the oats pass undigested through the body. For most of us, that would happen. Indeed, we are not cows. Neither are we horses. People need to cook their oats.

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. The holographic coating can be applied to the surface of the steel coils, creating a visually stunning and unique effect.

- Q: Why?Which one should i get? I am just starting to learn Guitar. Which one would be better for me? What is the difference? I already got the acoustic nylon but i might return it... if the steel is better.

- A nylon string guitar, more properly called a classical guitar, is used almost exclusively for playing classical music. Unless you're interested in classical music you should avoid this guitar. Also, it is only played fingerstyle so you will not be able to learn how to use a pick, which is a valuable, necessary skill. Steel string acoustic guitars are used for a wide variety of music including rock, pop, folk, bluegrass, and more. This is a much more versatile guitar and is the one you probably should have bought.

- Q: What are the different types of steel coil edge condition options?

- The different types of steel coil edge condition options include mill edge, slit edge, and deburred edge. Mill edge refers to the natural edge of the steel coil as it comes from the mill, which may have slight imperfections. Slit edge is created when the coil is cut into narrower widths, resulting in smooth edges. Deburred edge involves removing any sharp burrs or rough edges from the coil, providing a clean and safe edge for handling.

- Q: I saw a 27 sedan and a 27 Pick-up one had wood wheels the other steel, respectively. Witch one was original or were they both original

- Steel wheels were not available on the pickups until 1929. The cars had the options of steel disc or wood spoke wheels in the mid '20's. I'm pretty sure that '27 was the last year the wood wheels were available on passenger cars.

- Q: What are the various surface finishes available for steel coils?

- Steel coils offer a range of surface finishes, each with its own properties and uses. Some commonly used finishes include: 1. Hot rolled: Steel is rolled at high temperatures, resulting in a rough surface. This finish is great for structural applications like construction materials and industrial machinery. 2. Cold rolled: Steel is rolled at room temperature, creating a smoother surface. It is commonly used in automotive and appliance manufacturing due to its superior finish and accuracy. 3. Galvanized: Steel is coated with zinc to protect against corrosion. Galvanized coils have a shiny appearance and are suitable for outdoor applications such as roofing and fences. 4. Electro-galvanized: Coated with a thinner layer of zinc through an electroplating process, these coils offer good corrosion resistance. They are commonly used in electrical appliances, automotive parts, and construction. 5. Pre-painted: Coated with paint or polymer film, pre-painted coils provide both corrosion protection and aesthetic appeal. They are extensively used in construction for roofing, cladding, and wall panels. 6. Stainless steel: Stainless steel coils have unique properties, including corrosion resistance, heat resistance, and chemical damage resistance. They are ideal for industries like food processing, medical equipment, and marine applications. These examples showcase the variety of surface finishes available for steel coils. The choice of finish depends on factors such as the intended use, desired appearance, and level of corrosion resistance required.

- Q: What are the common applications of galvanized steel coils?

- Galvanized steel coils are commonly used in various applications such as construction, automotive manufacturing, electrical appliances, and infrastructure projects. They are used for manufacturing roofing sheets, wall panels, pipes, gutters, and various structural components due to their corrosion resistance and durability. Additionally, galvanized steel coils are widely used in the production of automotive parts, such as body panels, frames, and chassis, as they provide excellent strength and protection against rust.

- Q: What are the different types of steel coil finishing tools?

- There are several different types of steel coil finishing tools used in the metalworking industry. These tools are designed to add various finishes to steel coils, enhancing their appearance and functionality. Some of the common types of steel coil finishing tools include: 1. Slitting Machines: These tools are used to cut large steel coils into narrower strips. Slitting machines have sharp circular blades that can efficiently slice through the coil, resulting in multiple smaller coils of desired widths. 2. Levellers: Levellers are used to flatten and straighten steel coils. They apply pressure to the coil, ensuring that it is perfectly flat and even. Levellers are particularly useful when the steel coils have undergone deformation during the manufacturing process. 3. Recoilers: Recoilers are used to rewind steel coils into a tighter and more compact shape. These tools are typically used after slitting or levelling to create coils of a specific diameter or size. 4. Edge Trimmers: Edge trimmers are used to remove any excess or uneven edges from the steel coils. They can remove burrs, rough edges, or any other imperfections, resulting in a clean and smooth finish. 5. Inspection Machines: Inspection machines are used to examine the quality of the steel coils. These tools can detect any defects, such as surface imperfections, scratches, or dents, ensuring that only high-quality coils are delivered to customers. 6. Coating Machines: Coating machines are used to apply protective coatings to steel coils. These coatings can be in the form of paint, zinc, or other materials, preventing corrosion and enhancing the durability of the coils. 7. Packaging Machines: Packaging machines are used to wrap the steel coils securely and protect them during transportation and storage. These machines can apply plastic or metal straps, shrink wrap, or other packaging materials to ensure the coils remain intact and undamaged. Overall, these different types of steel coil finishing tools play a vital role in the metalworking industry, allowing manufacturers to produce high-quality and visually appealing steel coils that meet the specific requirements of their customers.

- Q: so my parents gave me stainless steel cookware for christmas and the first time i used it i cooked chicken. it stuck to the pan and where the oil splattered it cooked on and turned it dark black and brownish. and the bottom too. i don't cook with it because i don't want to burn it on anymore but i don't know how to clean it. how do i cook without burning anything, aside from a lower flame and how on earth do i get the stains on. i've tried almost everything too! thanks.

- Use oven cleaner. It will take off the burnt on stuff just like it does in the oven. Spray it on, put the cover on the pot and let it sit for a while. If the problem is on the outside, do the same but put the whole thing in a garbage bag to control the fumes. Wash the pot like you would normally to get the oven cleaner off. You will want to wear gloves too. Oven cleaner is very caustic. By the time you realize you are being burned by it, it's too late. The oven cleaner should do nothing to the finish of the stainless.

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- Surgical Steel Knives

Send your message to us

Galvanized Steel Sheet Coils in High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords