GALVANIZED STEEL COILS SGCC

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Galvanized steel coil

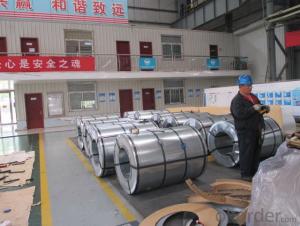

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

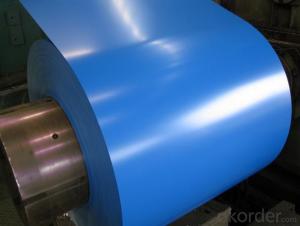

Commodity

Hot dip galvanized steel coil

Technical Standard:JIS 3302 / ASTM A653 / EN10143/ GB/T 2518

Grade:DX51D/ S250,280,320GD,SGCC,SGHC,SGH340,SGH400,SGH440,G450,G550

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

Surface treatment:zero spangle / regular spangle/ big spangle

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package:Properly packed for ocean freight exportation in 20''container

Application::home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

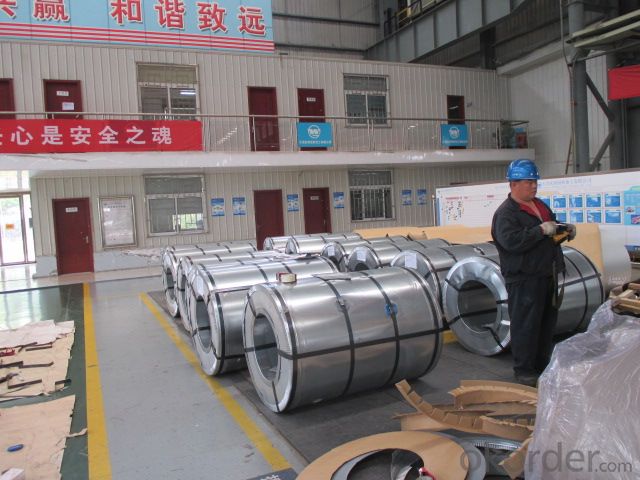

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of products

- Q: Where can you buy a steel polearm in a shop or if someone has a file in Scania than can you sell me one ill buy it for 150k my account is tonypark500

- you dont buy it, you earn it in the lottery cassandra was doing(it passed).

- Q: How are steel coils used in the manufacturing of construction formwork?

- Steel coils are used in the manufacturing of construction formwork to provide structural stability and reinforcement. The coils are processed and shaped into various components, such as beams, columns, and panels, which serve as a framework for pouring concrete. The strength and durability of steel make it an ideal material for withstanding the pressure and weight of the concrete, ensuring the stability and longevity of the formwork during construction.

- Q: I've seen on TV that stainless steel laminate sheets can be purchased and and used to cover appliances to give it a faux stainless steel look. They mentioned it was important to not have any bubbles (of course) and to work slowly. It's easy to do on a dishwasher, but what about the fridge? The handles are in the way? Do you have to take the handles off? Can anyone find a tutorial for me?

- There okorder appliance paint 2. What you are referring to really is not laminate steel sheets, it's actually more along the lines of shelf liner paper looks like steel with sticky back film that you peel and stick. Place against product and begin to peel down slowly using squeegee or credit card to smooth out bubbles.Sheets can be purchased rangingin size on OKorder for $9.99 + dependent on size. Called stainless steel appliance film can buy a roll for $60.00 on OKorder (normally sells for $100.00) one roll will cover 3 average sized kitchen appliances. Hope this helps!

- Q: What are the different methods of coil blanking for irregular shapes?

- Coil blanking for irregular shapes can be achieved through various methods. Among these methods, one commonly employed technique is laser blanking. By utilizing a high-powered laser, the shape is directly cut from the coil with exceptional precision. This method proves especially effective for intricate shapes, minimizing wastage. Another approach is water jet blanking, where a forceful stream of water mixed with abrasive particles is employed to cut the shape from the coil. Water jet blanking is particularly suitable for thicker materials or situations where heat sensitivity is a concern. Additionally, die blanking involves the utilization of a die to stamp out the desired shape from the coil. This method is frequently applied in large-scale production runs and can be automated for improved efficiency. Lastly, plasma blanking utilizes a plasma torch to cut the shape from the coil. It is commonly employed for thicker materials or situations requiring high cutting speeds. The choice of coil blanking method for irregular shapes is dependent on factors such as material thickness, shape complexity, production volume, and desired precision. Each method possesses its own advantages and limitations, necessitating careful selection to achieve optimal results.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- stainless steel also rusts it just takes longer to. what you have is just a higher grade of steel, which isn't stainless anyways so yeah wipe it clean when you're done.

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: How are steel coils used in the agricultural industry?

- Steel coils are commonly used in the agricultural industry for various purposes, such as manufacturing equipment like plows, harrows, and cultivators. They are also used for constructing storage structures like grain bins, as well as fencing and livestock enclosures. Additionally, steel coils are used in the construction of agricultural machinery and vehicles, ensuring durability and strength in demanding farming conditions.

- Q: How are steel coils used in the manufacturing of heat shields?

- Steel coils are used in the manufacturing of heat shields by being formed and shaped into the desired size and shape, providing a strong and durable base. The coils are then typically coated with heat-resistant materials and layered to create an effective barrier against heat transfer, making them essential components in the production of heat shields.

- Q: We are going to build a house with a steel frame.Someone told me today that these houses have problems with humidity.Is that true?Please tell me all you know..

- Steel frame houses are built using a modern method of construction (MMC) with an impressive strength to weight ratio and great design flexibility. The modern steel industry has been making in-roads to residential construction and material price reductions in the 1960 s made it a more affordable option.

- Q: I just got a set of all-clad Stainless steel frying pans, they are very nice yet they didn't come w/ instructions to care for them. I have never cooked w/ stainless steel cookware so I really don't know much about them. I was told they should have a lifetime warranty on them, but I don't want to reck them. I would appreciate any information I can get on stainless steel cookware. Thanks.

- Here's what All Clad has to say: Cleaning Cleaning the Stainless Steel Interior: Immerse in warm water. Use a fine powder cleanser with water to form a paste. Apply paste using a soft cloth. Rub in a circular motion from the center outward. Wash in hot, soapy water, dry immediately. DO NOT USE oven cleaners or cleansers with chlorine bleach. DO NOT USE steel wool. Cleaning the Steel Stainless Exterior: The polished stainless steel exterior of All-Clad Stainless requires very little care. It may be polished with one of the available commercial stainless steel cleaners, rubbing in a circular motion. Rinse in lukewarm water. We do not recommend using steel wool, steel scouring pads or harsh detergents. Nylon scrubbing pads are safe to use. You may wash Stainless in the dishwasher. The cleaners that they're talking about here are: Soft Scrub Bon Ami Barkeeper's Friend Those are the LEAST abrasive and won't harm your pans.....look for them in the cleaning aisle of your supermarket......How do you like your All Clad, BTW?? Just wondering......Enjoy!! Christopher

Send your message to us

GALVANIZED STEEL COILS SGCC

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords