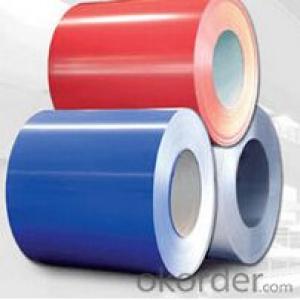

Prepainted Galvanized Rolled Steel Coil SGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Prepainted Galvanized Steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion .

Specification:

Thickness:0.15-0.8mm

Width:600-1250mm

Length:on request

Zinccoating: 30-275g/m2

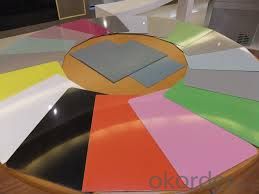

Color:RAL series

Paint:PE, PVDF, PU

Application:

1.Buildings and constructions:roofing, ceilings, gutters, venting lines, indoor decorations,windowframes, etc

2.Electrical appliances:computer shells, washing machines, refrigerators, dehumidifiers,videorecorders, water heaters, etc.

3. Agriculturalequipments: troughs, feeding tools, agricultural driers, irrigation channels,etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Packaging & Delivery

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images:

- Q: ok I got a dpms ar 15 and all i have put though it is good brass 223 ammo but is it ok to shoot the old crappy steel cased wolf ammo out of it will it hurt its function or will it hurt it cosmetically?

- The Wolf ammo and the rest of its ilk also has steel bullet jackets, so it will wear your barrel faster than copper jacketed ammo. Plus you can't reload it. I've also seen a few manufacturers say not to use it as pressures may be erratic. I wouldn't buy it to shoot unless I was shooting it in someone else's rifle, I would buy it to stash though.

- Q: How are steel coils used in the manufacturing of electrical components?

- Steel coils are commonly used in the manufacturing of electrical components as they provide a sturdy and reliable framework. They are used to create magnetic cores, which play a crucial role in transformers, motors, and generators. Additionally, steel coils are utilized in the production of inductors and solenoids, where they help generate and control magnetic fields. Overall, steel coils are essential in electrical component manufacturing due to their ability to enhance the efficiency and functionality of these devices.

- Q: I have a steel garage, it looks worn out hauled away? How can I maintain / repair it?

- The entire garage is steel? Garage door? Are you able to open and close it without too much trouble? If so, just keep it lubricated. You could paint the door to improve its appearance.

- Q: How are steel coils coated to prevent corrosion?

- Steel coils are coated to prevent corrosion through a process called galvanization. In this process, the steel coils are submerged in a bath of molten zinc, creating a protective zinc coating on the surface. This zinc coating acts as a barrier, preventing oxygen and moisture from coming into contact with the steel, thus inhibiting corrosion.

- Q: How are steel coils used in the manufacturing of industrial valves?

- Steel coils are used in the manufacturing of industrial valves as they provide the necessary material for constructing the valve bodies and other components. The steel coils are processed and shaped into the desired form, ensuring the valves are durable and can withstand high pressure and temperature conditions.

- Q: Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything like that, if not then I need to know what are other ways of testing the 1944 penny.

- This Site Might Help You. RE: 1944 Steel Penny? Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything...

- Q: is it much difference between 1095 and 1080,,,1065,,,1060 or even 1045 steel?please help and thanks!

- 1060 Carbon Steel

- Q: I work at a tool store. I told my boss last week we needed more pruning shears so he did get more of all kinds. Thing is out of all of the shears he brought Two of different kinds say they are made out of Japanese steel. I have never heard of Japanese steel so now i ask you (the public) whats the difference between it and steel from the US or any other country? Those shears are worth more then the ones he gets from Mexico and China and even more than Black and Decker, Fiskars, etc but not more then Corona brand ones.

- I doubt japanese steel has any special quality in its own, but they might just be higher quality shears. For example, Chinese qualities are good depending on what they are, but are usually not professional made with the greatest equipment. Same for Mexico. The company that makes them might just put more effort into making sturdier and sharper shears and thus make them more expensive, but Corona might make them a bit better so they are priced less than Corona's.

- Q: What are the different methods of roll forming steel coils?

- There are several different methods of roll forming steel coils, each with its own unique characteristics and applications. Some of the most common methods include: 1. Traditional Roll Forming: This is the most widely used method and involves passing a continuous strip of steel through a series of rollers to gradually shape it into the desired profile. This method provides high precision and repeatability, making it suitable for producing complex shapes and profiles. 2. Pre-Punch and Cut: In this method, the steel strip is pre-punched with holes or slots before it is roll formed. This allows for easier cutting and shaping of the material during the forming process. Pre-punching and cutting can improve efficiency and reduce waste in certain applications. 3. Post-Punch and Cut: This method is similar to pre-punching and cutting, but the holes or slots are added after the roll forming process. This allows for more flexibility in creating custom shapes and designs, as the holes can be placed precisely where needed. 4. Post-Forming: In some cases, the steel strip may be first roll formed into a basic shape or profile and then further manipulated or formed after the initial roll forming process. This method allows for additional customization and can be used to create more complex geometries. 5. Progressive Roll Forming: This method involves passing the steel strip through a series of rollers in a continuous process, with each roller gradually adding a specific feature or forming a particular part of the final profile. Progressive roll forming is commonly used for long, continuous profiles with repetitive shapes. 6. Incremental Roll Forming: In this method, the steel strip is incrementally formed by a series of small movements of the rollers. This allows for greater flexibility in shaping complex profiles and can be particularly useful for producing prototypes or low-volume production runs. Overall, the choice of roll forming method depends on the specific requirements of the application, such as the desired shape, complexity, precision, and production volume. Each method offers its own advantages and limitations, and manufacturers often select the most appropriate method based on these factors.

- Q: Okay basically bought my girlfriend Tiffany sterling silver necklace for her birthday and now christmas is coming up i want to buy her this DG Necklace. BUT i have discovered its steel. And its ?110. I am not a rich man i am infact quite young and we have been together for an incredibly long time! I wanted to know is Steel seen as a cheap necklace, whats your say? Don't give me all this bull about her being grateful as she does not expect this. BUT I WANT IT TO BE NICE. Whats your say? Is Steel good? Does it get dirty? Does it shine? Is it worth it? Thanks x

- Steel necklaces are popular these days. They certainly have a different look than silver. I think they have an 'edgier' look, so it depends on your girl's style. If you like it, and you think she will, go for it. If you're into showing emotional affection, you could accompany the gift with some sort of card or note saying something about your love is as strong as steel. She'd probably dig it. I would.

Send your message to us

Prepainted Galvanized Rolled Steel Coil SGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords