SGCC/SGLCC/Coated Alumimum Zinc Coils/ Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

SGCC/SGLCC/Coated Alumimum Zinc Coils/Galvanized Steel Coil

1. Application of Coated Alumimum Zinc Coils/Galvanized Steel Coil:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

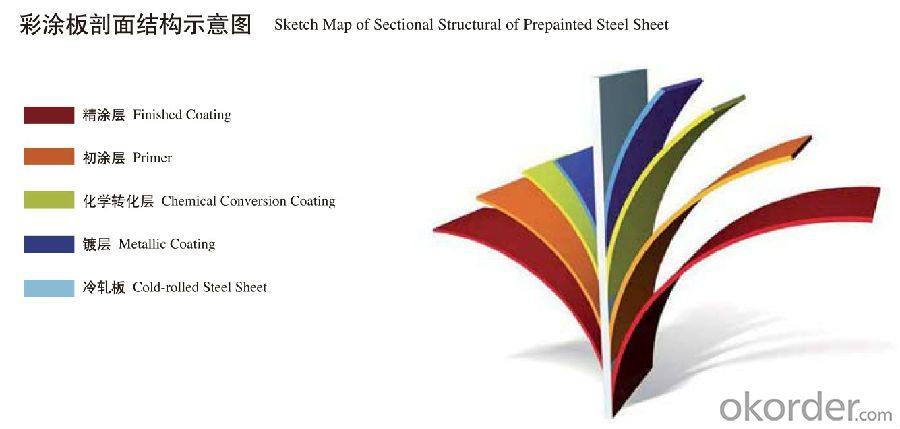

2.Features of Coated Alumimum Zinc Coils/Galvanized Steel Coil:

* uses hot dip galvanized steel sheet as the base material

* zinc layer protection, dope on the zinc layer can cover and protect the

steel base from corrosion

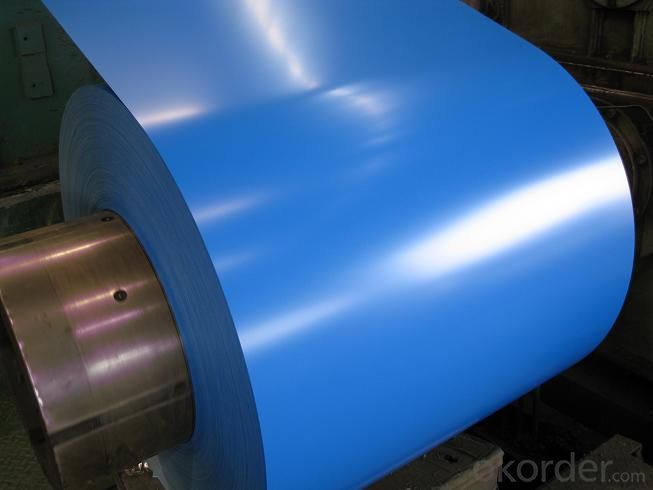

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of Coated Alumimum Zinc Coils/Galvanized Steel Coil:

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

4. Coated Alumimum Zinc Coils/Galvanized Steel Coil images:

APPLICATION:

PROUDUCTION LINE:

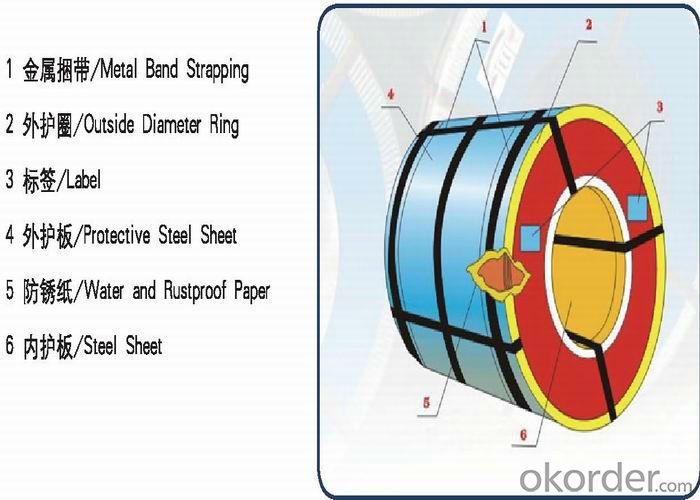

4. Packing:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Hi, I live in the Boston area and I'm trying to find a steel suppler that can provide mild steel for hobby welding. I can go through my job, but we only put in orders every couple of months so it's not very convenient. Also, the few suppliers I've found only sell in bulk. So if anyone knows where I can angle irons, flat bars, sheets, etc... by the piece it would greatly appreciated. Thanks

- They will sell any quantity of metal and even cut it to size - my experience has been that their prices are not wildly out of line for single pieces of full length stock compared to buying singles where you have to buy a minimum. They also may have sizes that ordinary places consider odd. I was looking for 5/8 square 16 gauge and was told it would have to be shipped in from Houston (to Dallas) by my nearest supplier and found it in stock at MetalSM. But check if you get something odd - the 5/8 cost more than 3/4 at both places and MetalSM actually gave me 3/4 but took it back even though I had cut it. Also check the regular steel suppliers in your area as well as retail welders metal supply places.

- Q: What temp does fire have to be to melt steel?

- You need about 2800 degrees to melt steel.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. Steel is a highly recyclable material, and steel coils can be melted down and used to produce new steel products. Recycling steel coils not only helps to conserve resources and reduce waste but also contributes to a more sustainable and environmentally-friendly manufacturing process.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications, commonly used in industries such as automotive, construction, manufacturing, and appliances. They are utilized for making various products including automobiles, pipes, electrical appliances, roofing, and packaging materials.

- Q: How does stainless steel soap work? I have read the detailed explanation on Wikipedia, but their desciption seems skeptical on the actual chemical process that may take place from using such an item. Is there an actual scientific explanation to how stainless steel soap is able to clean your hands, when it is only a piece of metal?

- Metal Soap Bar

- Q: What is the process for uncoiling and recoiling steel coils?

- The process for uncoiling and recoiling steel coils involves several steps to ensure the safe and efficient handling of the coils. 1. Unloading: The steel coils are typically transported to the desired location using cranes or forklifts. They are carefully unloaded from the transportation vehicle and placed in a designated area. 2. Inspection: Before uncoiling, it is crucial to inspect the steel coils for any damage or defects. This step ensures that only quality coils are processed further. 3. Securing: Once inspected, the steel coils are secured to prevent any movement during the uncoiling process. This is done by using clamps or straps to hold the coils firmly in place. 4. Uncoiling: Uncoiling involves the gradual unwinding of the steel coil. This can be done manually or using specialized machinery such as uncoilers or decoilers. The coil is typically fed through a series of rollers that help guide the unwinding process. 5. Straightening: In some cases, the steel coil may need to be straightened before further processing. This can be done using straightening machines that apply pressure to remove any bends or twists in the steel. 6. Cutting: If required, the uncoiled steel coil may be cut into smaller sections or sheets. This can be done using shearing machines or other cutting tools. The dimensions and size of the cuts depend on the specific requirements of the project. 7. Recoiling: Once the desired processing steps are completed, the steel coil can be recoiled. This involves rewinding the steel into a new coil shape. Recoiling can be done manually or using recoilers, which wind the steel evenly and tightly to maintain its integrity. 8. Packaging and storage: After recoiling, the steel coils are typically packaged and stored for further transportation or use. They may be wrapped in protective materials such as plastic or metal sheets to prevent corrosion or damage. Overall, the process for uncoiling and recoiling steel coils requires careful handling, inspection, and the use of specialized machinery. By following these steps, steel coils can be efficiently processed and prepared for various applications in industries such as construction, automotive, and manufacturing.

- Q: How do steel coils contribute to the water and wastewater industry?

- Steel coils are an essential component in the water and wastewater industry as they play a crucial role in the construction and maintenance of infrastructure. These coils are made from high-quality steel, which offers numerous advantages for the industry. Firstly, steel coils are used in the manufacturing of pipes and tubes that are primarily used for transporting water and wastewater. Steel pipes are known for their exceptional strength and durability, allowing them to withstand high pressure and heavy loads. This makes them ideal for water distribution systems, sewage networks, and treatment plants. Steel coils provide the necessary material for the production of these pipes, ensuring a reliable and long-lasting infrastructure. Moreover, steel coils are also utilized in the construction of storage tanks and reservoirs. These tanks are essential for water treatment plants, where they store large volumes of water or wastewater during the treatment process. Steel coils provide the necessary material for the fabrication of these tanks, ensuring their structural integrity and preventing leaks or contamination. Additionally, steel coils are used in the manufacturing of various equipment and components used in the water and wastewater industry. For instance, steel coils are utilized in the production of pumps, valves, and control systems, which are crucial for the efficient operation of water treatment plants, pumping stations, and sewage networks. Steel's strength and corrosion resistance make it an ideal material for these applications, ensuring reliable and long-lasting equipment. Furthermore, steel coils are also employed in the construction of wastewater treatment plants and facilities. These plants employ various processes to remove contaminants from wastewater before it is discharged into the environment. Steel coils provide the necessary material for the construction of these facilities, including structural supports, tanks, and other components. The durability and resilience of steel ensure the longevity and efficiency of these treatment plants. In summary, steel coils are integral to the water and wastewater industry due to their contribution to the construction and maintenance of critical infrastructure. They are used in the manufacturing of pipes, tanks, equipment, and facilities, ensuring the strength, reliability, and durability necessary for the efficient operation of water and wastewater systems.

- Q: So carbon is gas that brakes down to hydrogen and helium before going in...And steel can go a little farther towards sun before evaporating.. 200 degrees closer at leastso steel is full of a heavier gas bomb in my hypothesis and needs to be broken up outside stars(broken down)Is steel capable of going into sun with an element thats wrong wayLike iron has no air to boil outAnd steel goes just as far with carbon in it..Other words can u answer me with..Carbon is already IN the sun and is capable of braking down Carbon INSIDE the star/sunOnly way I see steel boiling is inside and it releases carbon gas at once..carbon bomb

- Hi: okorder /

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- I'm afraid you have opened a can o'worms. Aluminum as a material is roughly 1/2 the weight of steel. Aluminum as a material is also roughly 1/3 the strength of steel. his means you need 3 times more aluminum to make a frame as strong as steel which makes the aluminum frame 25% heavier. That being said, well designed and more expensive aluminum frames can easily weigh less than low zoot steel. Buying a cheap bike with an aluminum frame will ALWAYS weigh more than a middle of the road bike with a steel frame. ...and THAT being said, high end steel can easily weigh less than a high quality aluminum frame... note we are talking frames in the $2000 range- just for the frame. So, based on your explanation and attendant budget of the bikes you are considering, buy the steel bike. You won't be losing or gaining anything... except saving money.

Send your message to us

SGCC/SGLCC/Coated Alumimum Zinc Coils/ Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords