Galvanized Steel Coil with No Spangle in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

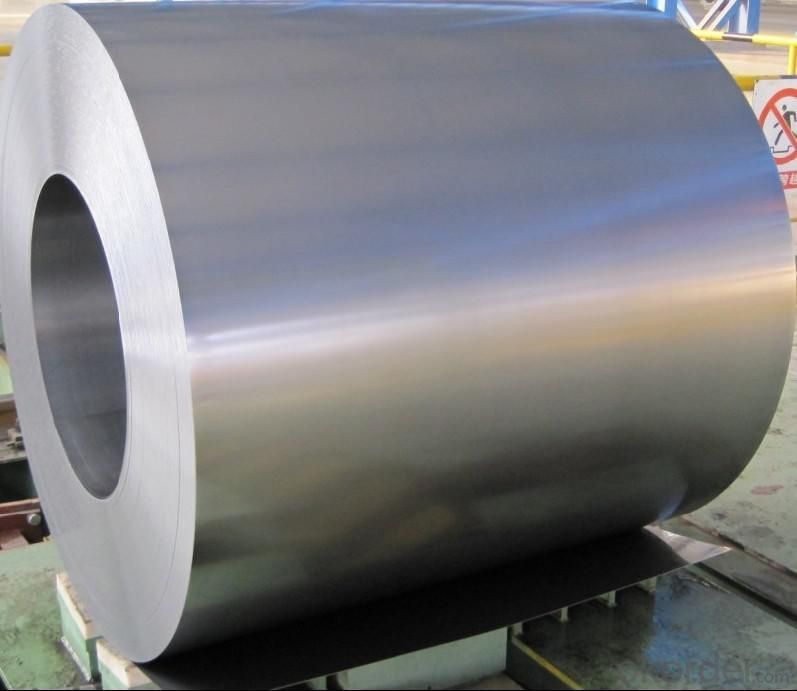

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

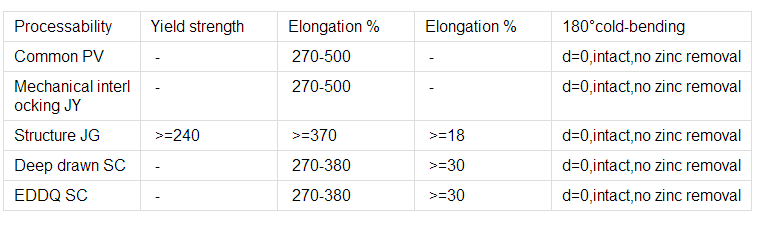

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet :

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized, galvannealed, and organic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvannealed coatings involve a two-step process where the steel is first galvanized and then heated to form an alloyed surface layer, offering enhanced paint adhesion and weldability. Organic coatings, on the other hand, use paints or other protective coatings to provide corrosion resistance and aesthetic appeal.

- Q: Are steel coils used in construction?

- Yes, steel coils are commonly used in construction. They are used for various applications such as structural framing, roofing, walls, and other components in buildings and infrastructure projects. Steel coils provide strength, durability, and flexibility, making them a popular choice in construction.

- Q: What are the different methods of stretch leveling steel coils?

- There are several methods of stretch leveling steel coils, each with its own advantages and applications. 1. Roller Leveling: This method involves passing the steel coil through a series of rollers that apply pressure to stretch and flatten the material. It is a widely used method for leveling steel coils and offers good control over the leveling process. Roller leveling is suitable for thin and medium gauge steel coils. 2. Tension Leveling: In this method, the steel coil is subjected to high tension forces applied by a set of bridle rolls. The tension helps to elongate and flatten the material, resulting in a level and stress-free coil. Tension leveling is particularly effective for thicker and harder steel coils. 3. Laser Leveling: Laser technology is employed in this method to measure and correct any imperfections in the steel coil. A laser scanner scans the surface of the coil and detects variations, which are then adjusted by a laser beam. Laser leveling offers high precision and is suitable for leveling sensitive and high-value steel coils. 4. Stretcher Leveling: This method involves stretching the steel coil beyond its yield point, which causes the material to permanently deform and eliminate any residual stresses. Stretcher leveling is commonly used for heavy gauge coils and can achieve significant flatness improvements. 5. Tensionless Leveling: As the name suggests, tensionless leveling is performed without applying tension to the steel coil. Instead, hydraulic or pneumatic pressure is used to stretch and flatten the material. This method is suitable for delicate or sensitive steel coils that may be prone to damage under high tension forces. Each method of stretch leveling steel coils has its own advantages, such as control, precision, or suitability for specific types of steel coils. The choice of method depends on factors like the thickness, hardness, and quality requirements of the steel coil, as well as the desired flatness and surface finish.

- Q: What are the different types of steel coil recoiling methods?

- There are three main types of steel coil recoiling methods: slit edge recoiling, mill edge recoiling, and oscillated recoiling.

- Q: What are the characteristics of hot-rolled steel coils and cold rolled steel coils? What loading and unloading tools should be used? What items should be paid attention to?

- When placing materials to roll on both sides of the main pad wood pallets, prevent rolling back and forth. In addition the floor should be thickened, cannot have uneven or debris, because the line of steel coils when gravity concentrated in contact with the ground floor, there is a fracture easily, debris, easy to leave the indentation in the steel roll.

- Q: How are steel coils annealed to improve their properties?

- Steel coils are annealed by heating them to a specific temperature and then slowly cooling them, which allows for the recrystallization of the steel. This process helps to relieve internal stresses, improve the material's ductility, and enhance its overall mechanical properties.

- Q: Which movie is better and why?I say Man of Steel!

- Captain America: The First Avenger

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials. This coating process enhances the electrical conductivity of the steel coils and allows them to conduct electricity efficiently.

- Q: What are the challenges in coil blanking for complex shapes?

- In order to achieve accurate and efficient results, there are several challenges that need to be addressed when it comes to coil blanking for complex shapes. One of the main challenges lies in the precise positioning and alignment of the coil material. When dealing with complex shapes, intricate cutting patterns are often required, and any misalignment or deviation can result in inaccurate cuts and wasted material. Another challenge involves the selection and optimization of the blanking tooling. Specialized dies and punches are often necessary for complex shapes, and these need to be carefully designed and manufactured to ensure accuracy and consistency. This not only involves choosing the right tooling materials but also considering factors such as cutting forces, wear resistance, and tool life. The complexity of the shapes also presents challenges in terms of material deformation and springback. During the blanking process, the material undergoes various deformations and stresses, which can cause distortions and dimensional variations in the final product. Achieving the desired shape while minimizing these deformations requires a deep understanding of material properties and advanced techniques like compensation and adjustment in the die design. Furthermore, the high-speed nature of coil blanking for complex shapes can result in increased vibration and noise levels. The dynamic forces involved in cutting intricate shapes can lead to tool chatter and excessive noise, affecting both the quality of the cut and overall operational efficiency. It is vital to implement effective damping and vibration control measures, such as tool coatings and optimized cutting parameters, to address these challenges. Lastly, the complexity of the shapes can impact production efficiency. Complex shapes often require longer tool setup times and more frequent tool changes, leading to increased downtime and reduced productivity. Additionally, the intricate nature of the cuts may require multiple passes or additional machining operations, further adding to the production time and complexity. To overcome these challenges, manufacturers need to invest in advanced technologies like computer-aided design and simulation software to optimize the blanking process. Continuous research and development efforts focused on improving tooling materials, cutting techniques, and process control can also help address the challenges associated with coil blanking for complex shapes.

- Q: What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and applying protective films. These methods help prevent corrosion, rusting, and damage to the steel surface during storage, transportation, and processing.

Send your message to us

Galvanized Steel Coil with No Spangle in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords