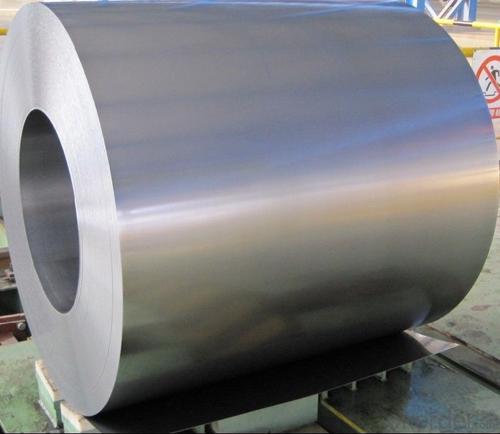

Hot Dip Galvanized Steel Coil Zero Spangle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q: How are steel coils used in the production of electrical connectors?

- Steel coils are used in the production of electrical connectors as they are often used as a raw material for manufacturing the connector pins. The steel coils are typically shaped and cut to specific dimensions to create the pins, which are then inserted into the connectors to establish electrical connections.

- Q: How are steel coils affected by global trade policies?

- Steel coils are significantly affected by global trade policies as they are subject to various tariffs, quotas, and trade restrictions imposed by different countries. These policies can impact the cost, availability, and competitiveness of steel coils in the international market. Changes in trade policies can lead to fluctuations in demand and supply, impacting the prices and trade volumes of steel coils.

- Q: How are steel coils inspected for thickness?

- Steel coils are inspected for thickness using various methods to ensure their quality and compliance with industry standards. One common method is using a non-contact laser measurement system. In this process, a laser beam is directed towards the surface of the steel coil, and the time it takes for the beam to reflect back is measured. By accurately calculating the time taken, the thickness of the steel coil can be determined. Another method involves using ultrasonic technology. Ultrasonic sensors are used to emit high-frequency sound waves that penetrate the coil. These sound waves bounce back differently depending on the thickness of the steel, allowing the sensors to measure the thickness accurately. Additionally, some manufacturers may opt for an eddy current testing method. This technique involves passing an alternating current through a coil, creating a magnetic field. The thickness of the steel coil affects the impedance of the coil, which can be measured. By analyzing the changes in impedance, the thickness of the steel coil can be evaluated. Furthermore, some companies employ a mechanical method called the caliper method. This method involves using a caliper gauge to physically measure the thickness of the steel coil by applying pressure to the coil and reading the measurement on the caliper. Regardless of the method used, it is crucial for steel coils to be inspected for thickness to ensure they meet the required specifications and provide the desired performance in various applications.

- Q: How are steel coils used in the production of steel knobs?

- Steel coils are used in the production of steel knobs by being uncoiled and fed into a stamping press, where the steel is formed into the desired knob shape. This process allows for efficient mass production of steel knobs with consistent quality and strength.

- Q: Can steel coils be coated with scratch-resistant materials?

- Yes, steel coils can be coated with scratch-resistant materials. These coatings are typically applied to the surface of the steel coils to enhance their durability and protect them from scratches and abrasions.

- Q: How are steel coils used in the production of heating and cooling systems?

- Steel coils are used in the production of heating and cooling systems as they serve as the primary component for heat transfer. These coils are designed to efficiently transfer heat or cool air, allowing for the effective regulation of temperature in heating and cooling systems.

- Q: Steel is a mixture of Iron Carbon . So , is steel a metal or non - metal ?

- This Site Might Help You. RE: Is Steel a Metal or Non - Metal ? Steel is a mixture of Iron Carbon . So , is steel a metal or non - metal ?

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

- Q: How are steel coils inspected for coil set using deflection measurement?

- Steel coils are inspected for coil set using deflection measurement by subjecting the coil to a controlled force and measuring the amount of deflection or bending that occurs. This is typically done by placing the coil on a support system and applying a known load or weight onto the center of the coil. The deflection or displacement of the coil is then measured using sensors or devices that can accurately detect any changes in the coil's shape. This measurement helps to identify any potential coil set, which is a condition where the coil retains a curved or bent shape even when unrolled.

- Q: How are steel coils tested for compliance with industry standards?

- Steel coils are tested for compliance with industry standards through various methods. These include visual inspection, dimensional measurements, and mechanical tests such as tensile and impact tests. Additionally, chemical composition analysis is performed to ensure that the steel meets the required specifications. These comprehensive tests ensure that the steel coils are of high quality and meet the standards set by the industry.

Send your message to us

Hot Dip Galvanized Steel Coil Zero Spangle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords