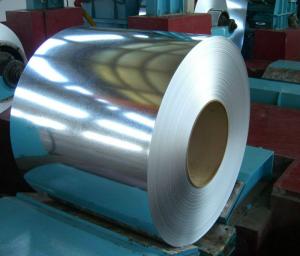

prepainted galvanized steel coil manufacturer made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | 300 Series | Standard: | JIS,AISI,GB | Length: | as customers' requested |

| Thickness: | 0.1-120mm | Width: | 1000-2000mm | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CNBM | Model Number: | 309S | Type: | Coil |

| Application: | petroleum refining | Certification: | SGS, ISO | Color: | natural color |

| Packing: | Standard export seaworthy packing or according to your requirements | Available Finish: | 2B/BA/8K/No.4/SB/HL | Edge: | slit edge and mill edge |

| Features: | accurate dimensions | Manufacture technology: | cold drawn,pickling, hot rolled and cold rolled | Quality: | high quality 201, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

| Stock: | Always in stock | Item: | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Packaging & Delivery

| Packaging Detail: | Standard export packing or as customer's requirement ASTM 309S Stainless Steel Coil |

| Delivery Detail: | In 15 days |

Specifications

201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil

Width:1000-2000mm

Thickness: 0.1-120mm

Quality:High quality

Product Description

ASTM 309S Stainless Steel Coil

Thickness:0.1-120mm

Width:1000-2000mm

Length: As required

Typical physical properties for stainless steel coil

Grade | Chemical composition | ||||||

C | Si | Mn | P | S | Ni | Cr | |

% | % | % | % | % | % | % | |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.030 | 12.00-15.00 | 22.00-24.00 |

Item | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201, 202,301, 304,316,304L,316L,309,410,430 |

Surface | NO.1,2B, mirror finish,4K,8K,Hairline finish |

Thickness | 0.1-120mm |

Width | 1000-2000mm |

Price term | FOB,CFR,CIF,CNF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

- Q: Just wondering how good are forge steel screw drivers, tool boxes(organisers) and pliers are, as screw fix are having a january sale, and looking to add to my tool collection. Thanks in advance

- Go craftsman not bad prices and lifetime warranty.

- Q: What are the different types of steel coil storage systems?

- There are several different types of steel coil storage systems, including coil racks, coil cradles, coil saddles, and coil bunks. Each of these systems is designed to safely and efficiently store steel coils in a warehouse or manufacturing facility. Coil racks are typically used for larger, heavier coils and have adjustable arms to accommodate different sizes. Coil cradles are used for smaller coils and provide a stable base for storage. Coil saddles are specifically designed to hold and transport coils with overhead crane systems. Coil bunks are used for storing large quantities of coils and provide a stacking system to maximize space utilization.

- Q: I heard that titanium isn't the most hypoallergenic metal because it is treated and the chemicals can cause an allergic reaction. I also heard that surgical steel is the best because it is what is used in surgery and in hip replacement implants etc. Is this correct?I've always heard that titanium is best, but now I'm curious because surgical steel is much cheaper than titanium which can be expensive.Thanks

- Implant grade titanium is much better than surgical steel. The nickel content in it (which is what alot of people are allergic to) is virtually non-existant. Though most people with a nickel allergy are fine with surgical steel too, its too small for most people to react to. But the odd few people do. Its the same with everything. Good surgical steel is probably better than cheap titanium. But implant grade ti will beat it hands down. And ti is alot stronger, and is also used in surgical impants and as replacement bits too. But a big lump of titanium hip is going to be expensive. If you're not allergic to steel, theres little reason for the extra cost, especially if it's likely to outlive you. Niobium has no nickel in at all. But that really is expensive, and I've never seen any threaded. Any particular reason why you ask? ----- Piercing-wise titanium will be better than steel. Unless they carry some not so great ti. You should be fine with steel though.

- Q: What is the weight of a typical steel coil?

- The weight of a typical steel coil can vary significantly depending on its size, thickness, and type of steel used. However, a typical steel coil can range anywhere from a few hundred kilograms to several tonnes in weight.

- Q: How many millimeters is a number 3 steel crochet hook?

- In the rest of the world, a #3 hook is 6.5 mm. But the thing to do is use the hook size according to the yarn you are using. You would never follow the pattern exactly for hook size, you know that! You must do a gauge swatch to find out what YOUR tension is, and if that yarn will make the kind of fabric YOU want. You need to do a little research on this... as you know. Don't you remember your first lesson when you took your basic beginner class? Review your notes.

- Q: Can we construct a barn using steel and will it be a durable one?

- Steel barns in the USA is the going fad; they are both strong and economical; and some companies offer DIY kits

- Q: The Iron and Steel Corporation of Great Britain (1949) or Iron and Steel Bill was introduced in 1949 during the Labour post-war Government.What was it introduced for?

- It was a holding company that originally had 107 companies who manufactured iron or steel products in Great Britain.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws as they serve as the raw material for manufacturing the screws. The steel coils are unwound and fed into a machine that cuts and shapes the steel into the desired screw form. This process ensures that the screws are made from high-quality steel and have the necessary strength and durability.

- Q: Hey guys do you know anything about Steel Arch Building and how this structure really looks like?

- Just google steel arch building, you will get plenty of selection , pictures, prices and designs

- Q: What are the common coil storage conditions?

- The common coil storage conditions include storing coils in a dry and clean area, away from direct sunlight and extreme temperature variations, and ensuring proper ventilation to prevent moisture buildup. It is also important to stack the coils properly, avoiding any damage or deformations, and to label and organize them for easy identification and retrieval.

Send your message to us

prepainted galvanized steel coil manufacturer made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords