Galvanized Steel Coil of Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

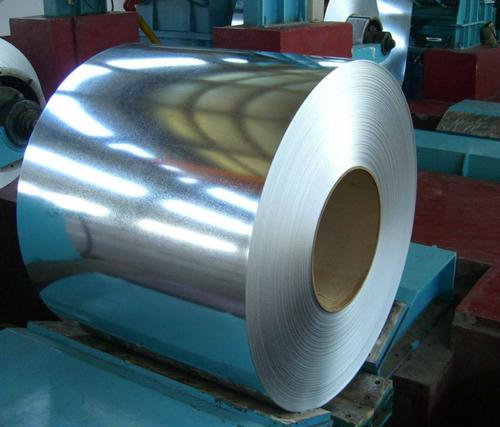

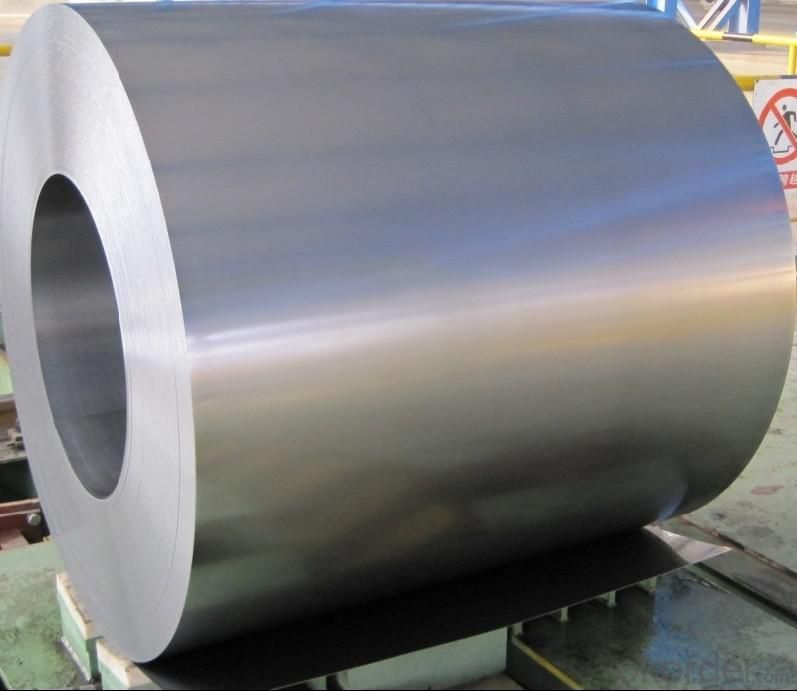

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the HVAC industry?

- Steel coils are commonly used in the HVAC industry for various purposes such as heat transfer, refrigerant circulation, and air conditioning. They are typically found in heat exchangers, condensers, and evaporators, where they help in transferring heat between air and refrigerant. Steel coils play a crucial role in maintaining the desired temperature and providing efficient cooling or heating in HVAC systems.

- Q: What are the safety precautions for handling steel coils?

- When handling steel coils, it is important to follow certain safety precautions to prevent accidents and injuries. Some of these precautions include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against cuts, impacts, and eye injuries. It is also essential to ensure proper training and knowledge of correct lifting techniques to avoid strains or back injuries. Additionally, using equipment like cranes or forklifts with appropriate capacity and stability is crucial for safe handling and storage of steel coils. Regular inspection and maintenance of equipment, as well as adhering to proper storage procedures, are also important safety measures to prevent incidents.

- Q: All of my friends say that if a car made of mostly carbon fiber would crash into a full steel car, or vice versa, the steel car would be DESTROYED and the carbon fiber would drive away, if not, easily repairable.

- Depends on the design/construction.

- Q: How are steel coils used in the manufacturing of pipes and tubes?

- Steel coils are used in the manufacturing of pipes and tubes by being unwound and fed into a pipe or tube mill. The steel coils are then shaped and welded together to form a continuous pipe or tube, which is further processed and finished according to specific requirements.

- Q: i want to know if i should buy a set of acrylic tapers or steel. they r close in cost so it's not a money factor i want to know which work better and if there is a downside to either. thanks!

- Steel is better. Acrylic is porous so isn't as suitable for piercing jewellery as steel. Steel can also slide through easier for some people, acrylic isn't quite as smooth. For tapers it doesn't make a huge deal of difference as they're only passing through your ear briefly, not being worn as jewellery, but if they're close in cost anyway then go for the steel. And the plugs you insert after putting the taper through should always be steel, titanium or glass until your stretch has healed.

- Q: can steel boil and turn into a gaseous state?? if so how hot does it have to be for it to boil

- The amount of heat needed can be generated. The heat on the surface of the sun is sufficient. Steel will break down before it gets that hot. The carbon in the steel will oxidize into carbon dioxide, or vaporize into carbon gas. The outer core of the Earth is composed of molten iron and nickel. Its also done in steel plants every day.

- Q: I have two guitars, a nylon stringed classical, and a steel stringed acoustic, I find the nylon strings easier to play, but doesn't have as good of sound as the steel stringed, and when I play with the steel strings, it really hurts my fingers, and if I play just a little bit, it feels like the high e string is going to cut my finger. Are the strings too high? What can I do to make the steel strings easier to play?

- If you want to end up playing acoustic steel string, continue learning on that one. Yes, it will hurt, but that's normal and your fingers will toughen up within a couple of weeks of playing (if you play on a regular basis). You will develop callouses. Also, go take your guitar to a shop to get a set up and they will fix the action if it's too high. (Too high action makes the guitar harder to play). When I started playing, at first my fingers *HURT*, but now they don't anymore, even the pinky. :D

- Q: How are steel coils protected from extreme weather conditions?

- Steel coils are typically protected from extreme weather conditions through the application of a weather-resistant coating or paint. This coating acts as a barrier, shielding the steel from moisture, UV radiation, and other environmental elements that could cause corrosion or damage. Additionally, steel coils may be stored in covered or enclosed areas to further protect them from rain, snow, and other severe weather conditions.

- Q: How do steel coil manufacturers handle customer complaints?

- Customer complaints in the steel coil manufacturing industry are addressed and resolved through a structured process. The manufacturer begins by carefully listening to and understanding the nature of the complaint. This involves actively engaging with the customer to gather all relevant information and ensure clear communication. Upon full comprehension of the complaint, the manufacturer promptly investigates the situation. This may involve reviewing production records, analyzing quality control measures, or conducting internal inspections. The goal is to identify the root cause of the problem and determine any contributing factors. Once the investigation is complete, the manufacturer provides a timely response to the customer. This response includes an explanation of the findings, an acknowledgement of the customer's concerns, and a proposed solution or resolution. The proposed solution may involve replacing defective coils, offering compensation, or providing expert advice to mitigate the issue. To prevent future complaints, the manufacturer takes steps to rectify any internal shortcomings. This could involve revisiting quality control procedures, improving communication among departments, or implementing additional employee training. Furthermore, maintaining open and transparent communication with customers throughout the complaint handling process is essential. Regular updates on the investigation's progress are provided, and any further concerns or questions from the customer are promptly addressed. In summary, prioritizing customer satisfaction and ensuring a fair and efficient resolution are crucial in handling customer complaints in the steel coil manufacturing industry. By following a structured approach, actively listening, and taking appropriate corrective actions, manufacturers can effectively address customer complaints and maintain positive client relationships.

- Q: What are chemical properties of high speed steel? Physical properties?What is high speed steel used for? One interesting fact about high speed steel?

- wikipedia: High speed steel (often abbreviated HSS, sometimes HS) is a material usually used in the manufacture of machine tool bits and other cutters. It is often used in power saw blades and drill bits. It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and a high abrasion resistance (generally linked to tungsten content often used in HSS) compared to common carbon and tool steels. see reference for more info .

Send your message to us

Galvanized Steel Coil of Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords