Galvanized Steel CoiLs of High Qualities

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08-Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Workability, durability

• Excellent anticorrosive property

• Excellent process capability

• High strength

• Smooth and flat surface

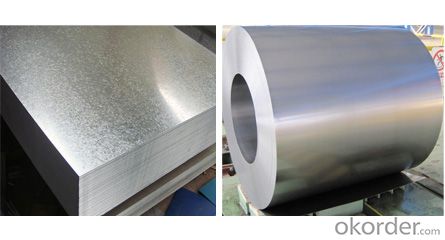

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Why does steel with several composites have a greater hardenability from quenching than low carbon steel alloys?Any help would be great

- Bit tricky to explain and I don't know muh about it but steel on its own has lost of gaps in it ( the molecular structure) and when carbon is added thos gaps are filled, I think of it like this: it is easier to punch through expanded polystyrene( with all the little balls) than unexpanded(just a lump of plastic) as the balls are not properly joined and have air pockets between them.

- Q: Hi, I live in the Boston area and I'm trying to find a steel suppler that can provide mild steel for hobby welding. I can go through my job, but we only put in orders every couple of months so it's not very convenient. Also, the few suppliers I've found only sell in bulk. So if anyone knows where I can angle irons, flat bars, sheets, etc... by the piece it would greatly appreciated. Thanks

- They will sell any quantity of metal and even cut it to size - my experience has been that their prices are not wildly out of line for single pieces of full length stock compared to buying singles where you have to buy a minimum. They also may have sizes that ordinary places consider odd. I was looking for 5/8 square 16 gauge and was told it would have to be shipped in from Houston (to Dallas) by my nearest supplier and found it in stock at MetalSM. But check if you get something odd - the 5/8 cost more than 3/4 at both places and MetalSM actually gave me 3/4 but took it back even though I had cut it. Also check the regular steel suppliers in your area as well as retail welders metal supply places.

- Q: Hi, I would like to know if steel is an important material in desalination plants. If it is, could you specify what type of steel is used (i.e. flat steel products, long steel products, etc). Thanks.

- If stainless steels were used they would have to be high grade, high Chromium-Nickel alloyed stainless steels. The best in the range would be the Stainless Steel 316 series with superior corrosion resistance and strength. The downside to this is the expense. Carbon steel may be used but only if reinforced with a more corrosive resistant element

- Q: Molten steel changes to solid steel at its __________ point. Could you please fill in the blank? Thank you so much, it is greatly appreciated. I have been looking for the answer to this question for a long time, but I never understand what the websites are trying to say because I don't have that big of a vocabulary and don't know what they mean. I've seen things saying steel boiling point, steel melting point, and steel freezing point. I don't know what any of those mean, and they might be the answer. Please help me. Thank you.

- just like a melting point of ice and the boiling point of water, there are different points where something is converted into another form. such as icewatersteam. it's always the same thing and it's a physical change, but just in a different form. molten steel changes to solid steel at it's freezing point. or solid point. i'm not sure how you would word that. but it would not be melting or boiling point. hope that helped.

- Q: Can steel coils be coated with decorative designs?

- Yes, steel coils can be coated with decorative designs. This is commonly achieved through various coating techniques like painting, powder coating, or laminating, which can add aesthetic appeal to the steel coils while enhancing their overall appearance and functionality.

- Q: Can steel coils be coated with zinc?

- Yes, steel coils can be coated with zinc through a process called hot-dip galvanization or electroplating. This coating of zinc helps protect the steel from corrosion and rust, extending its lifespan and improving its durability.

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Wood is made up of elements which are non-metals with a high electron affinity. Specifically, carbon, oxygen, hydrogen, and some nitrogen. Furthermore the covalent bond structure in wood means electrons are tightly bound and cannot move easily from atom to another. Not without adding a great deal of energy to the first. Steel is mostly iron, which is a metal. Metals have low electron affinity. The outer electrons in metals are bound very loosely, so that they can move from atom to atom using almost no energy. Metals tend to conduct electricity very easily.

- Q: How are steel coils used in the manufacturing of fuel systems?

- Steel coils are commonly used in the manufacturing of fuel systems for their strength, durability, and resistance to heat and corrosion. These coils are typically formed into various components such as fuel tanks, pipelines, and fuel lines. The steel coils provide structural support and ensure the integrity of the fuel system, enabling safe and efficient transportation, storage, and delivery of fuel.

- Q: What are the different types of steel grades used for coil production?

- There are several types of steel grades used for coil production, including carbon steel, stainless steel, and alloy steel. Carbon steel is the most common type and is widely used due to its affordability and versatility. Stainless steel is highly resistant to corrosion and is often used in applications where hygiene and appearance are important. Alloy steel, on the other hand, contains additional elements such as manganese, nickel, and chromium, which enhance its strength and durability. Each type of steel grade has its own unique properties and is chosen based on the specific requirements of the coil production process.

- Q: Ok so i have a certain amount of money that I want to invest in either GE or US Steel. Tickers: ge, x. GE looks like a strong co, but less risk. Whereas US Steel looks risky, but high reward. :). i am willing to take risks. Any comments?

- I would go with some in one and less in the other. Given that steel prices have collapsed (and seeing as the Chinese economy is going into a recession, they will probably stay low for a while) I would say that because US Steel is a blue chip company it will be around for the long term, but, it won't make much for a while. GE on the other hand has been beaten down thanks to some mismanagement issues under current CEO Jeffrey Immelt, however, they have a range of strong products (save for their broadcast division, RCA/NBC). Given that the stock is at a severe low with the company itself being worth quite a bit (with a fair amount of bailout funds coming to its' financial division) and the Obama administrations' green initiatives coming online over the next couple of years the demand for their products will be high. I would simply say 70/20 GE/US. Good luck.

Send your message to us

Galvanized Steel CoiLs of High Qualities

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords