Galvanized Steel Coil in China Galvanized Zinc Sheet Galvanized Steel in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR GALVANIZED STEEL COILS:

Mian Quality Standard | JIS G3302, EN10346, DIN17162, ASTM A653/653M, GB2518 |

Process | hot dip galvanizing |

Process Speed | 1#. Max 120m/min, 2#. Max 130m/min |

Thickness | 1#. 0.25mm upto 1.20mm, 2#. 0.25mm upto 1.0mm |

Width | 900mm upto 1300mm |

Surface Finish | zero spangles, skinpassed, oiled,chromated, tension level, |

Coating | zinc layer mass on both sides from 30 g/m2 upto 180g/m2 |

Yield Strength | 220Mpa upto 750Mpa |

Weight per Coil | max 15,000kg |

Inner Diameter | φ 508mm |

Outer Diameter | max φ 2,050mm |

Finished Internal Diameter | Φ 508mm or φ 610mm |

Finished Coil Weight | 1#. max 10,000kg, 2#. max 15,000kg |

Packing | Mill's Export Standard Packing |

Capacity | 300,000 tons/year |

EXPORT STANDARD FOR GALVANIZED STEEL COILS:

-Axial and circumferential steel straps with seal (4 steel straps each)

-VCI Anti-rust kraft paper

-Water-proofing plastic

-Pearl wool (coil surface)

-Steel cover (coil surface/bore)

-Plastic cover (coil sides)

-Inside and outside corner protectors

Or According customers' requirements(Usually only for domestic)

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS FOR GALVANIZED STEEL COILS:FOB, CFR, CIF

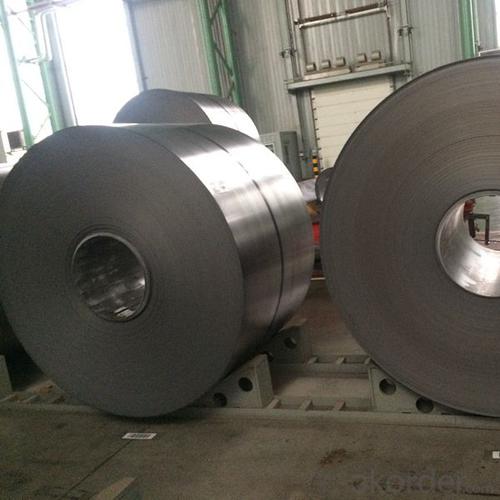

DETAILED PICTURES FOR GALVANIZED STEEL COILS:

APPLICATION FOR GALVANIZED STEEL COILS:

Galvanized steel products are mainly used in construction, light industry, automobile, agriculture , fishery and commercial industries. They have great advantages:1.it has small harm to the environment and it can be recycled, greatly lighten the stress to the environment.2.it is convenient to process,easy to construct and has good waterproof effect.

FAQ FOR GALVANIZED STEEL COILS:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

- Q: Can stainless steel sheets be used for decorative elevator doors or panels?

- Yes, stainless steel sheets can be used for decorative elevator doors or panels. Stainless steel is a versatile material that is known for its durability, sleek appearance, and resistance to corrosion. It can be easily shaped, engraved, or finished in various ways to create visually appealing designs for elevator doors or panels. Additionally, stainless steel's hygienic properties make it a popular choice for elevator applications.

- Q: Can stainless steel sheets be used for decorative room dividers or partitions?

- Yes, stainless steel sheets can be used for decorative room dividers or partitions. Stainless steel is a versatile material known for its durability, strength, and resistance to corrosion, making it a popular choice for various applications. When used as room dividers or partitions, stainless steel sheets can add a sleek and modern aesthetic to any space. They can be customized with different finishes, such as brushed, mirrored, or patterned, to create a unique and decorative look. Stainless steel dividers or partitions are also easy to clean and maintain, making them a practical choice for high-traffic areas or commercial spaces. Overall, stainless steel sheets offer both functionality and style, making them suitable for use as decorative room dividers or partitions.

- Q: What is the average lifespan of stainless steel sheets?

- The average lifespan of stainless steel sheets can vary depending on various factors such as the grade and quality of the stainless steel, the environment in which it is used, and the level of maintenance and care it receives. Generally, stainless steel sheets are known for their durability and longevity. They are designed to resist corrosion, rust, and other forms of degradation, making them suitable for a wide range of applications. In ideal conditions and with proper maintenance, stainless steel sheets can last for several decades or even longer. However, in more aggressive environments with exposure to harsh chemicals, extreme temperatures, or high levels of moisture, the lifespan of stainless steel sheets may be reduced. Regular cleaning, proper storage, and routine inspections are important to ensure the longevity of stainless steel sheets. By following recommended maintenance practices, stainless steel sheets can provide reliable performance and a long lifespan.

- Q: What are the different types of stainless steel sheet finishes for marine applications?

- There are several types of stainless steel sheet finishes commonly used for marine applications, including 2B, #4, and #8 mirror finishes. 2B finish is a smooth, matte finish with good corrosion resistance, while #4 finish has a brushed appearance and is commonly used for aesthetic purposes. #8 mirror finish is highly reflective and provides a polished, mirror-like appearance, often preferred for its decorative appeal.

- Q: Are stainless steel sheets suitable for storage cabinets?

- Yes, stainless steel sheets are suitable for storage cabinets. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an excellent choice for storage cabinets. Stainless steel sheets are able to withstand heavy loads and can resist damage from moisture, heat, and chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storage cabinets. Overall, stainless steel sheets provide a long-lasting and reliable solution for storage cabinets in various environments such as kitchens, laboratories, and industrial settings.

- Q: Can stainless steel sheets be used for heat transfer applications?

- Stainless steel sheets are indeed applicable for heat transfer purposes. Renowned for its superb heat transfer characteristics, stainless steel is widely favored for diverse applications that require heat transfer. Its exceptional thermal conductivity ensures effective heat transfer, guaranteeing even distribution of heat throughout the surface. Furthermore, stainless steel exhibits resistance to corrosion and oxidation when exposed to high temperatures, making it a suitable choice for heat transfer applications in extreme heat or corrosive environments. In conclusion, stainless steel sheets are a dependable and long-lasting option for heat transfer applications.

- Q: What are the different types of stainless steel sheet thickness tolerances?

- The different types of stainless steel sheet thickness tolerances include standard, tight, and extra tight tolerances. Standard tolerances allow for slight variations in thickness, tight tolerances have lower permissible deviations, and extra tight tolerances have even smaller allowable variations in thickness.

- Q: Can stainless steel sheets be used in medical applications?

- Certainly, medical applications can indeed utilize stainless steel sheets. The medical sector favors stainless steel for its remarkable resistance against corrosion, its durability, and its simplicity when it comes to sterilization. It finds extensive employment in medical devices, surgical instruments, and implantable components, as it can endure rigorous sterilization procedures like autoclaving. This capability is pivotal in upholding cleanliness and averting infections. Moreover, stainless steel is biocompatible, signifying that it does not interact negatively with bodily tissues or induce any harm or adverse responses. All in all, stainless steel sheets are an unwavering and adaptable material suitable for a plethora of medical applications.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are highly suitable for medical equipment or devices. Stainless steel is corrosion-resistant, durable, and easy to clean, making it ideal for use in medical settings where cleanliness and sterility are crucial. It also possesses excellent strength and can withstand high temperatures and harsh environments, making it a reliable choice for medical equipment that needs to endure rigorous use. Additionally, stainless steel is non-reactive, ensuring that it does not interact with medications, bodily fluids, or tissues, which is essential for maintaining the safety and efficacy of medical devices.

- Q: What are the standard dimensions for stainless steel sheets?

- The dimensions of stainless steel sheets differ based on the type and grade of stainless steel utilized. Nevertheless, there exist some widely available common sizes in the market. Typically, the standard width for most stainless steel sheets falls within the range of 36 to 48 inches, while the length can vary between 72 to 120 inches. These dimensions are commonly employed in construction, automotive, and manufacturing applications. The thickness of stainless steel sheets can also vary, with common choices ranging from 0.024 to 0.1875 inches. Thinner sheets are often used for decorative or lightweight purposes, whereas thicker sheets are utilized for heavy-duty applications requiring enhanced strength and durability. It is essential to note that these dimensions are general guidelines and may differ depending on specific project requirements. Moreover, custom sizes can be manufactured to meet the unique needs of a particular application. Overall, the standard dimensions for stainless steel sheets provide a range of options suitable for diverse industries and purposes. This ensures flexibility in selecting the appropriate size for a specific project.

Send your message to us

Galvanized Steel Coil in China Galvanized Zinc Sheet Galvanized Steel in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords