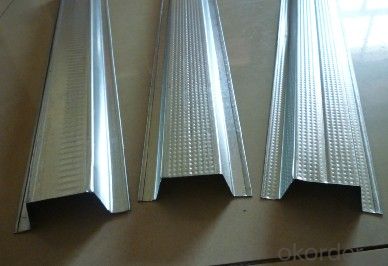

Galvanized Steel Ceiling Profile for Drywall Partition System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Lightgage Steel Joist

1.according to standard of GB/T11981-2001

2.adopting advanced domestic equipment

3.modern technique

4. Origin of China

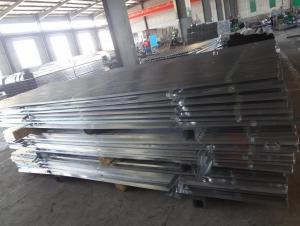

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

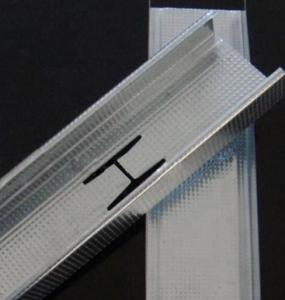

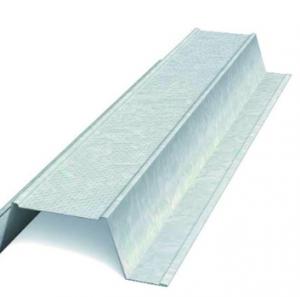

3.Image

4.Detailed Specification

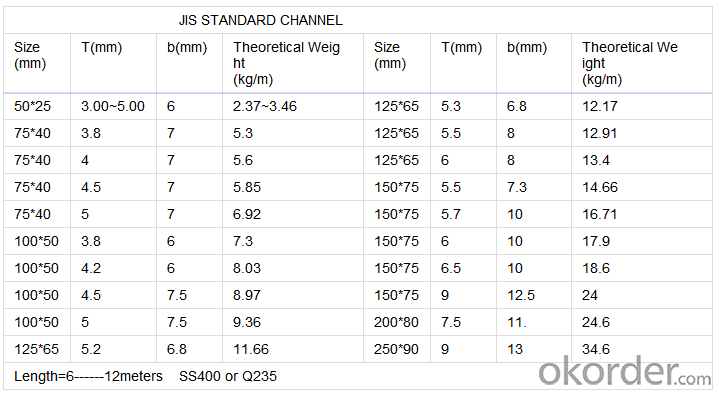

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

5.FAQ

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

8. around 25 tons can be loaded in 1x20'FCL.

- Q: Please give valid certificate, thank you! The

- The keel of the ceiling needs to be re-examined: Detection parameters Keel: size deviation, mechanical properties; Accessories: size deviation, mechanical properties. Keel ceiling project quality acceptance project: Ceiling elevation, size, from the arch and shape should meet the design requirements. Test method: observation; scale inspection. The material, variety, specifications, regiment and color of the facing material should meet the design requirements. When the facing material is a glass plate, use safety glass or take reliable safety measures. Inspection method: observation; check product certificate of competency, performance testing report and admission inspection records. Finishes should be tightly installed. The overlapping width of the facing material and the keel should be greater than two-thirds of the width of the keel. Test method: observation; hand pull check; scale check. Boom, keel material, specifications, installation spacing and connection should meet the design requirements. Metal boom, keel should be surface corrosion treatment; wood keel should be anti-corrosion, fire treatment. Inspection methods: observation; foot check; check product certificate of competency, admission acceptance records and hidden engineering acceptance records.

- Q: Light steel keel ceiling The first main keel distance from the wall should be how much? To be specific.

- W fixed spacing of the boom 900-10OOmm pitch, in the event of beam and pipe fixed point is greater than the design and procedures requirements, should increase the fixed point of the boom. W is not on the ceiling, boom length is less than 10OOmm, you can use φ6 boom, if more than 10OOmm, should be used φ8 boom, should also set the reverse support. W Master's ceiling, boom length is equal to 10OOmm, you can use φ8 boom, if more than 10OOmm, should be used φ10 boom, one end of the boom with L30X30X3 angle welding (corner of the aperture should be based on boom and expansion Bolt diameter to determine), the other end can be tapped out with more than 100mm screw, you can also buy finished screw welding.

- Q: Wood keel expensive or light steel keel expensive?

- Hello there! Wood keel with light steel keel which expensive? There are two possibilities, if the material by material to measure the two materials, it is light steel keel expensive. If used in the project of the ceiling, in accordance with the standard construction process construction, that light steel keel cost will be cheaper.

- Q: What kind of thickness of the light steel keel there is no specification?

- If the space is not too big, no special requirements, the general can,

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The effect of the two ceiling is the same, but the material is different, light steel keel price is relatively cheap, the best light steel keel material with accessories per square price of not more than 15 yuan, detailed specifications, the unit price is as follows: 1.0 main keel each Square 2 5,0.5 pairs of keel 8 per square, boom diameter 8MM 1 2, accessories 2 per square, loss plus a little on the line This ratio is limited to flat top, and only to the building materials market, light steel keel store to have such a price Oh, the decoration company fucking offer to turn several times, not just a little bit high, be careful slaughtered. Gypsum board made of the dragon card is good, imported brands are Lafarge, Jieke, can be resistant, more than 20 dollars a count down every square as long as 10 less than How can it be professional? The The

- Q: What is the light steel keel?

- Light steel keel according to the use of hanging keel and cut keel, according to cross-section of the form of V-type, C-type, T-type, L-keel. (1) product specifications series of keel main specifications are divided into Q50, Q75 and Q100. The main specifications of the ceiling keel are divided into D38, D45, D50 and D60. (2) Product marking method The marking order of light steel keel is: product name, code, width of section shape, height, thickness of steel plate and standard number. Such as cross-sectional shape of "C" type, width of 50mm, height of 15mm, steel plate thickness of 1. Smm of the ceiling keel marked as: building light steel keel DC 5 0 XIS XI. SGBllg sl (3) the appearance of quality light steel keel shape to be smooth, angular, cut not allowed to affect the use of burrs and deformation. Galvanized layer is not allowed to have skin, from the tumor, shedding and other defects. For corrosion, damage, dark spots, pitting and other defects, according to the provisions of the method should be tested in accordance with the provisions of Table 2-81. Appearance quality inspection, should be 0.5m away from the product under the conditions of bright light, the visual inspection. Light steel keel surface should be galvanized rust, the double-sided galvanized: excellent products not less than 120g / m * m, first-class goods is not less than 100g / m * m, qualified products not less than 80g / m * m. Paint keel with cold-rolled continuous hot-dip galvanized steel strip and paint belt as raw material, through the cold bending process, composite rolling from a reasonable "T" -shaped structure of the thin-walled profile.

- Q: For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling of the keel spacing is too small to easily affect the ceiling of the sound effects and life. Keel skeleton is commonly used in the ceiling of the material, if the early construction of non-standard will seriously affect the aesthetic effect, and may even affect the safety of occupants. The spacing of the keel in the ceiling is very important. The spacing of the keel is different for different ceiling materials.

- Q: Play light steel keel cut off how not to damage the ceiling

- Can be found after the next day keel fixed, the other side can be used to do vertical keel shape, and then package edge

- Q: Light steel keel ceiling specifications require boom length greater than 1500MM to add anti-support, what is anti-support? How to set up? The best specific construction node map, thank you!

- When the hanging length of more than 1.5m should be set anti-support, reverse support is in the case of normal boom, from the lower end of the boom oblique ceiling installation to connect a rod, rod to have a certain stiffness, and the boom to form a Solid triangular. To prevent the ceiling in the air pressure when the upward deformation, the formation of dome, causing damage to the ceiling. The number of anti-support should be set according to the construction plan.

- Q: Which is more cost-effective, want to get a professional answer Oh, anxious decoration it

- The kind of keel is determined by the material of the ceiling. Light steel keel for, gypsum board, integrated ceiling, relief gypsum board mineral wool board (both bones for the paint). Kitchen and other basic not suitable, integrated ceiling can be. If only the ordinary buckle top, it must be wood keel, or can not be fixed pinch. On the issue of cost-effective, light steel keel and wood keel basically no comparable, the same area of the former price of the latter twice as much as the latter, but iron is better than wood. Home improvement basically no light steel keel, because the kitchen is not suitable, in the living room after the ceiling height than the keel to 10 cm lower.

Send your message to us

Galvanized Steel Ceiling Profile for Drywall Partition System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords