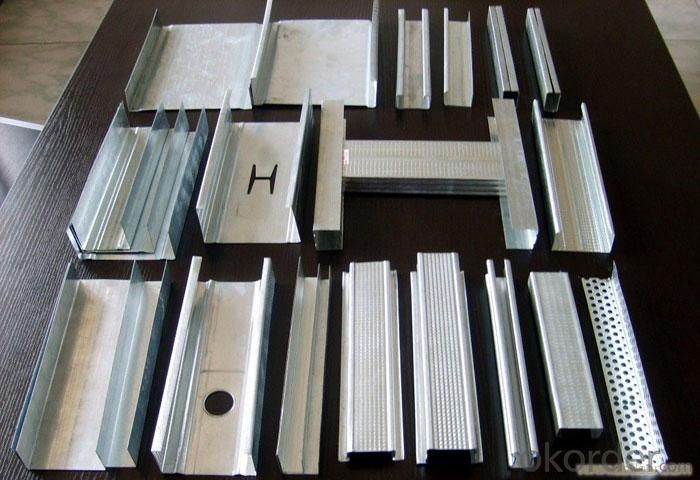

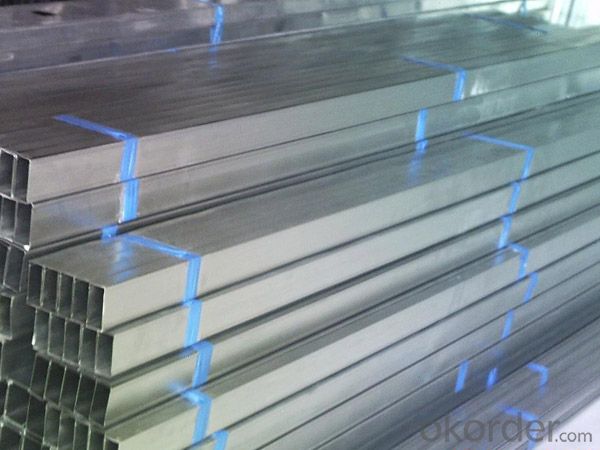

Gypsum Drywall Galvanized Steel Ceiling Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Lightgage Steel Joist

1.according to standard of GB/T11981-2001

2.adopting advanced domestic equipment

3.modern technique

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

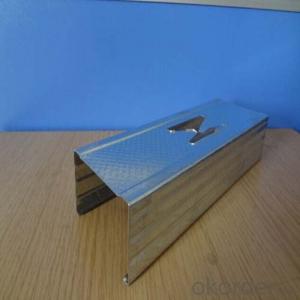

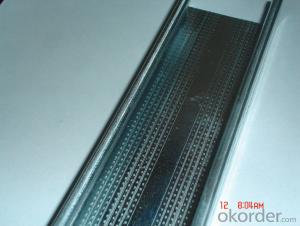

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

3.Image

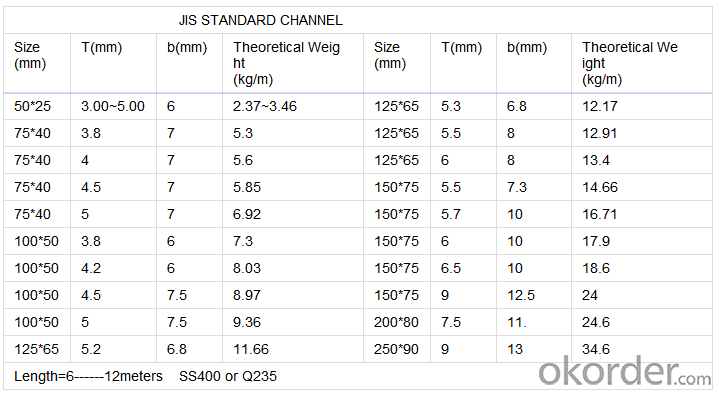

4.Detailed Specification

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

5.FAQ

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

- Q: I am a novice . The How the keel is fixed on the ceiling of the hairy house. The Also gypsum board ceiling gypsum board is how to install on the keel I think: it will not fall? Is it to take nails or what glue up? What is the use of the boom (the ceiling will seem to use ..)

- Now the ceiling is generally light steel keel gypsum board ceiling. First of all, the hanging wire with the expansion of silk fixed on the ceiling hanging under a hanging piece is fixed on the main dragon. There is a buckle on the main dragon is stuck in the vice dragon. And then the gypsum board is used by the self-Gong Luo Luo on the vice dragon. Under normal circumstances as long as the operation in accordance with the norms do not have to fall off. Please rest assured that the landlord.

- Q: Light steel keel ceiling calculation method

- Let the decoration of the people estimate, and then you go to buy.

- Q: Tectonic hierarchy of light steel keel

- Main machine The main equipment includes: saws, toothless saws, nail guns, hand saws, hand plane, pliers, screwdrivers, moving, square feet, steel ruler, steel level and so on.

- Q: Light steel keel ceiling price 60 level probably need much money

- A square about a hundred or so package materials

- Q: PVC plastic buckle plate ceiling with what keel ah?

- PVC gusset plate should be used "head" word dragon skeleton, keel spacing of 400mm-600mm, suspended skeleton to add boom, spacing 1m. Aluminum gusset used keel should be supporting keel, dragon keel spacing of 600mm, fixed boom should be supporting the simple telescopic boom to prepare for the adjustment of the dragon skeleton. Now the basic use of aluminum buckle plate plastic buckle plate market is rare to recommend the use of aluminum plate.

- Q: There are several specifications for light steel keel with household ceiling

- Wall steel ceiling keel specifications and information decoration materials Light steel keel wall materials are 50, 75, 100, 150 and several other Light steel keel thickness ranging from 0.4mm to 2.0mm. Under normal circumstances, the use of paper gypsum ceiling when most people will choose light steel keel, thin gypsum board using Pu keel, gypsum thick to use thick keel. There are two kinds of galvanized galvanized, one is hot galvanized, one is cold galvanized. Hot galvanized prices are high and cold galvanized prices are low. The ceiling keel consists of the keel (main keel), the cover keel (auxiliary keel) and various accessories. D38 (UC38), D50 (UC50) and D60 (UC60) three series. D38 for hanging point spacing 900-1200 mm not on the ceiling, D50 for hanging point spacing 900-1200 mm Master ceiling, D60 for hanging point spacing 1500 mm Master heavier ceiling, U50, U60 for the cover keel, it With the use of keel. The wall keel consists of horizontal keel, vertical keel and cross brace and various accessories. There are four series of Q50 (C50), Q75 (C75), Q100 (C100) and Q150 (C150) The width of the light steel keel is often used to refer to the keel model, such as the width of 50mm keel is called the 50 keel. Light steel keel side of the high known as the keel side of the high. Keel length is divided into 3 meters, 4 meters two. Keel each price between 12-20 yuan. Paper gypsum board per standard 2400 mm × 1200 mm) price between 22-30 yuan. Plus auxiliary materials costs and labor costs, the general light steel keel partition wall decoration price between 90 to 150 yuan per square meter. There are T line, C-shaped, U-shaped keel and so on.

- Q: Integrated ceiling and ordinary and wood keel ceiling difference and good or bad?

- Integrated ceiling to be installed naturally nothing to ceiling accessories - keel. So, the ceiling keel on the ceiling plays a clear support, fixed role. Wood keel ceiling is good or light steel keel ceiling is better? It has a fire and rust anti-aging and other characteristics, but also in the construction of convenient, decorative effect is also very good. Light steel keel is relatively heavy, a long time more or less there will be sagging tendencies. Advantages and Disadvantages of Integrating Ceiling with Wood keel and Light Steel Now the light steel keel generally have been treated with paint, moisture, waterproof performance trustworthy, with a lot of performance. The wood keel light, easy to install and the price is relatively low, but there are some children defect. Wood keel because the main body is wood, it is easy to burn and corrosion, easy to mold in the wet bathroom, which the whole ceiling will cause a great impact. Of course, now a lot of wood keel have done anti-corrosion treatment, but also the surface of the wooden keel is also painted fire protection materials. This greatly improved the role of wood keel. In general, the wood keel ceiling or light steel keel ceiling is good, they have their own advantages, in fact, now with the development of society, integrated ceiling are more light steel keel.

- Q: Light steel keel gypsum board ceiling lamp how to install

- This is not the most basic process? Cutter to open the downlight to buy the LED is the external spotlight effect is kind ~

- Q: Will the light steel keel ceiling be deformed?

- Generally not Please adopt If you acknowledge my answer, please accept it in time, ~ If you acknowledge my answer, please click on the "Accept Satisfactory Answer" button ~ ~ Mobile phone questions friends in the upper right corner of the client evaluation point [satisfaction] can be. ~ Your adoption is the driving force of my progress ~ ~ O (∩ _ ∩) O, remember praise and adoption, help each other

- Q: Wood keel and light steel keel were used for where?

- Light steel keel main use in a large area of the ceiling, the general home decoration in addition to kitchen and steel is used outside the light keel are used wood keel. Be sure to pay attention to full brush fire retardant coating.

Send your message to us

Gypsum Drywall Galvanized Steel Ceiling Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords