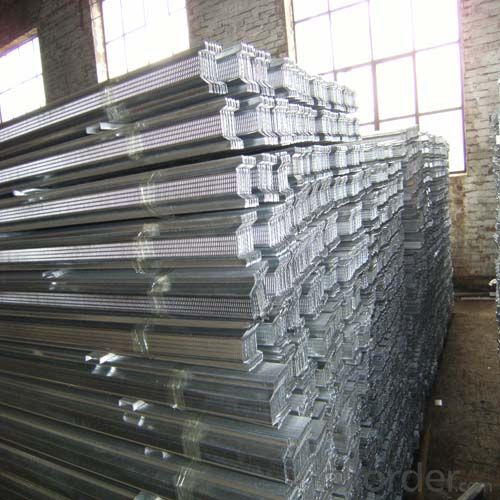

Galvanized Ceiling Drywall Steel Stud Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Discription of DRY WALL METAL PROFILE OF U CHANNEL ZINC GALVANIZED

1>adopting high-grade quality hot-dipped galvanized steel,

2>The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product.

Specification:

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Feature

(1) Ceiling solid structure, good safety performance

(2) Frame and light weight

(3) No rust, no corrosion, life is very long

(4) It can variety of shapes roofs

Product Overviews

FAQ

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method. 8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price *large quantity *honesty *good after-service

9.Certificates ISO 9001:2000 Quality management system

- Q: How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q: I was not a tool in the category, or else I got myself!

- Look at the size of the area. Small words are generally not the unit price of the normal words is to use a gypsum board with a gypsum board is 65 - 75 range.

- Q: The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- You know how to do it If you want to do their own, you need to find the location of the wall light steel keel, and then a layer of woodworking board fixed to the light steel keel, and then do the partition in the woodworking board. Very simple, you may be confused

- Q: What is the light steel keel gypsum board partition? What are the characteristics?

- According to the Austrian decoration experience, light steel keel gypsum board wall with simple construction, light, strong, fire-retardant, thermal insulation and other characteristics, the keel sub-vertical keel and horizontal sub-keel, commonly used width of 65,75, Can be fixed with self-tapping screws on the main keel. Keel can be filled with rock wool and other insulation materials.

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- But in a dry place, with a 20 years no problem, light steel keel life and its wall thickness, sealing plate varieties and thickness are closely related. Do not worry about the damp environment, it is recommended to use light steel keel partition, after all, it has light, space-saving, construction convenience, the cost is relatively low advantage.

- Q: Light steel keel wall Why do not cross brace welding with welding

- Then the book is too much trouble to weld, to master the master to welding, Moreover, the time is too long, so no one with the welding.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- 1, the main structure is completed, before the ceiling, the first wall construction. 2, light steel keel installation is completed, should be based on the construction acceptance of the keel for acceptance, such as skeleton does not meet the requirements, should be promptly adjusted. 3, the installation of gypsum board must be stress-free installation, first with self-tapping nail fixed gypsum board center parts, and then fixed the edge, so that the gypsum board after installation without any stress.

- Q: Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- I am a decoration worker, painter, there are a few details you need to add 1, before the black latex paint is how long to sit? 2, there is no grass-roots off, loose phenomenon? 3, need to transform the home improvement? Or tooling? Because each has a processing method? Need to be added to determine your home to change how to deal with the grassroots, gypsum board in addition to the degree of solidarity you can rest assured that the situation is not damp its structure is still very high!

- Q: Light steel keel partition wall how to get, and how to purchase materials and tools, I now empty-handed, the best comprehensive ~!

- You said there is still wet the ground, then use the light steel keel to do the wall, then, is not appropriate. Because gypsum board is not damp. Therefore, it is recommended that you use lightweight brick to cement mortar masonry walls as well, its strength is much better than the light steel keel, but also more solid, more durable, the operation is relatively simple, do not need so many power tools.

- Q: How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

Send your message to us

Galvanized Ceiling Drywall Steel Stud Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords