Galvanized Hexagonal Wire Netting Before Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

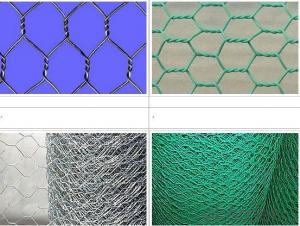

Pictures of Galvanized Hexagonal Wire Mesh Galvanized Hexagonal Wire Netting Before Weaving

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the different weaving patterns available in steel wire mesh?

- Steel wire mesh offers a variety of weaving patterns, each with its own distinct characteristics and uses. Some commonly used patterns include the following: 1. Plain Weave: The most basic and widely used pattern, plain weave involves interlacing wires in a simple crisscross manner. It is known for its strength, durability, and versatility. 2. Twilled Weave: In this pattern, each wire passes over two adjacent wires and under two others in a diagonal arrangement. Twilled weave offers a tight structure and high strength, making it ideal for applications requiring extra durability and resistance to wear and tear. 3. Dutch Weave: Dutch weave combines elements of plain and twilled weaves. It typically utilizes thicker warp wires and thinner weft wires, resulting in a tighter weave and smaller openings. Dutch weave is often used when precise filtration and separation are necessary. 4. Welded Wire Mesh: Unlike the previous patterns, welded wire mesh is not woven but rather created by welding individual wires at their intersections. This produces a strong, rigid mesh with consistent openings. Welded wire mesh finds common use in construction, fencing, and industrial settings. 5. Expanded Metal Mesh: Instead of weaving wires, expanded metal mesh is formed by cutting and stretching a metal sheet. This process creates interconnected diamond-shaped openings. Expanded metal mesh is lightweight yet sturdy, making it popular for architectural applications, filtration, and security purposes. These examples represent only a fraction of the weaving patterns available for steel wire mesh. The choice of pattern depends on specific requirements such as strength, filtration capabilities, and visual aesthetics.

- Q: How does the wire diameter affect the rigidity of steel wire mesh?

- The wire diameter directly affects the rigidity of steel wire mesh. A larger wire diameter generally results in a stiffer and more rigid mesh, while a smaller wire diameter leads to a more flexible and less rigid mesh.

- Q: Is steel wire mesh resistant to moisture?

- In general, steel wire mesh is resistant to moisture. Unlike other metals, steel is not easily affected by water and does not rust as easily. Moreover, the mesh design promotes air circulation, which prevents moisture buildup and potential harm. Nevertheless, it is worth mentioning that extended exposure to moisture, particularly in harsh conditions or when combined with corrosive elements, can still result in rust or corrosion over time. For optimal resistance, it is often advised to use stainless steel or galvanized steel wire mesh as they have added protective coatings that enhance their resistance to moisture and other corrosive substances.

- Q: Is steel wire mesh suitable for landscape design?

- Steel wire mesh proves to be an ideal choice for landscape design. Its versatility allows for a multitude of applications that not only enhance the aesthetics but also the functionality of outdoor spaces. Whether it's for fencing, trellises, or screens, this material offers both boundaries and privacy while introducing a contemporary and industrial vibe to the landscape. Moreover, the construction of raised beds becomes effortless with steel wire mesh, offering flexibility and creativity in gardening options. Furthermore, it serves as a sturdy support structure for climbing plants, enabling the creation of stunning vertical gardens. Its enduring durability and strength guarantee a long-lasting option that withstands harsh weather conditions and resists corrosion. By seamlessly blending with different materials and styles, steel wire mesh unlocks limitless possibilities for landscape design.

- Q: What are the different grades of steel used in wire mesh manufacturing?

- There are several different grades of steel that are commonly used in wire mesh manufacturing. These grades are determined based on the composition and characteristics of the steel, and each grade has its own unique properties and applications. One widely used grade of steel in wire mesh manufacturing is low carbon steel, also known as mild steel. This grade is popular due to its affordability, ease of fabrication, and good corrosion resistance. Low carbon steel wire mesh is commonly used in various applications such as filtration, fencing, and construction. Another grade of steel commonly used in wire mesh manufacturing is stainless steel. Stainless steel wire mesh is highly resistant to corrosion, making it suitable for outdoor and marine applications. It is also known for its strength and durability, making it ideal for heavy-duty applications such as mining, sieving, and security fencing. Stainless steel wire mesh is available in various grades, including 304 and 316, which offer different levels of corrosion resistance. High carbon steel is another grade used in wire mesh manufacturing. It has a higher carbon content, which provides increased strength and hardness. High carbon steel wire mesh is frequently used in industrial applications that require strong and durable mesh, such as mining screens, vibrating screens, and machine guards. Lastly, there are also specialty grades of steel used in wire mesh manufacturing. These include galvanized steel, which is coated with a layer of zinc for enhanced corrosion resistance, and alloy steel, which contains additional elements such as chromium, nickel, or molybdenum to improve specific properties like strength and heat resistance. Overall, the different grades of steel used in wire mesh manufacturing offer a range of properties and characteristics to meet various industry requirements. The choice of grade depends on factors such as the intended application, environmental conditions, and required strength or corrosion resistance.

- Q: How does the surface treatment affect the resistance of steel wire mesh to rust?

- The resistance of steel wire mesh to rust is greatly influenced by its surface treatment. Steel wire mesh can undergo various surface treatments, including galvanization, coating, or passivation. Galvanization involves the application of a protective layer of zinc onto the surface of the steel wire mesh. This layer of zinc acts as a barrier, preventing moisture and oxygen from reaching the steel underneath. As a result, the steel wire mesh becomes highly resistant to rust and corrosion. Another commonly used surface treatment for steel wire mesh is coating. This treatment entails applying a layer of protective material, such as paint or epoxy, onto the mesh's surface. This coating acts as a physical barrier, shielding the steel from environmental factors that cause rust. The effectiveness of the coating depends on its quality and thickness. Passivation, on the other hand, is a chemical treatment that eliminates impurities and forms a passive oxide layer on the surface of the steel wire mesh. This oxide layer serves as a protective barrier against rust and corrosion. Passivation is often combined with other surface treatments, such as galvanization or coating, to enhance the overall resistance of the steel wire mesh. Overall, the surface treatment of steel wire mesh directly impacts its ability to resist rust. Galvanization, coating, and passivation are all effective methods that improve the durability and longevity of the mesh by preventing rust formation. The choice of surface treatment depends on the specific application and the desired level of protection.

- Q: What are the different sizes and gauges available for steel wire mesh?

- Steel wire mesh is available in a variety of sizes and gauges to suit different applications and requirements. The sizes of steel wire mesh typically range from small, fine meshes to larger, coarser meshes. The sizes are usually specified by the number of openings per linear inch or by the clear opening size. Common sizes include 2 mesh (2 openings per inch), 4 mesh, 8 mesh, 16 mesh, and 30 mesh, among others. In terms of gauges, steel wire mesh is available in different thicknesses. The gauge of a wire refers to its diameter, with a lower gauge number indicating a thicker wire. Common gauges for steel wire mesh range from 6 gauge (0.192 inches) to 24 gauge (0.0201 inches), with 10 gauge, 12 gauge, and 14 gauge being commonly used. The selection of the appropriate size and gauge of steel wire mesh depends on the specific application. Fine mesh sizes are often used for sifting, filtering, and separating materials, while coarser mesh sizes are suitable for applications such as fencing, reinforcement, and protection. The choice of gauge depends on factors such as the desired strength, durability, and level of visibility required. It is worth noting that these sizes and gauges are standard measurements, but custom sizes and gauges can also be manufactured to meet specific project needs. Overall, the availability of different sizes and gauges allows for flexibility in choosing the most suitable steel wire mesh for a particular application.

- Q: Can steel wire mesh be used for creating gabion mattresses?

- Yes, steel wire mesh can be used for creating gabion mattresses. Gabion mattresses are typically made by filling steel wire mesh containers with stones or other fill materials to create erosion control structures. The steel wire mesh provides structural integrity and stability to the gabion mattress, making it an ideal material for this purpose.

- Q: What are the cost considerations for steel wire mesh?

- The cost considerations for steel wire mesh typically include factors such as the size and thickness of the mesh, the quality and composition of the steel used, the quantity needed, and any additional customization requirements. The prices of steel wire mesh can vary depending on these factors, so it is important to consider them when determining the overall cost.

- Q: Can steel wire mesh be used for bridge construction?

- Steel wire mesh is a versatile material that has several advantages for bridge construction. It can provide structural support, reinforcement, and stability to the bridge structure. The mesh is commonly installed in the form of panels or rolls in different sections of the bridge, such as the deck, beams, and columns. One of the main advantages of steel wire mesh is its high tensile strength, which allows it to withstand heavy loads and provide additional reinforcement to the bridge. This makes it suitable for constructing bridges that need to support significant weight, like vehicular bridges or pedestrian walkways. Additionally, steel wire mesh is corrosion-resistant, which is important for bridge construction because of exposure to various weather conditions and environmental factors. Its resistance to corrosion ensures the durability and longevity of the bridge structure, reducing the need for frequent maintenance and repairs. Furthermore, steel wire mesh offers flexibility in terms of design and construction. It can be easily shaped and molded to fit different bridge configurations, making it suitable for both simple and complex bridge designs. Moreover, it is lightweight compared to other construction materials, making it easier to handle and transport during the construction process. In conclusion, steel wire mesh is a suitable material for bridge construction due to its high tensile strength, corrosion resistance, and flexibility. It provides structural support, reinforcement, and stability to the bridge structure, ensuring its durability and longevity.

Send your message to us

Galvanized Hexagonal Wire Netting Before Weaving

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords