Welded Wire Mesh for Chicken Fence-1 X 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

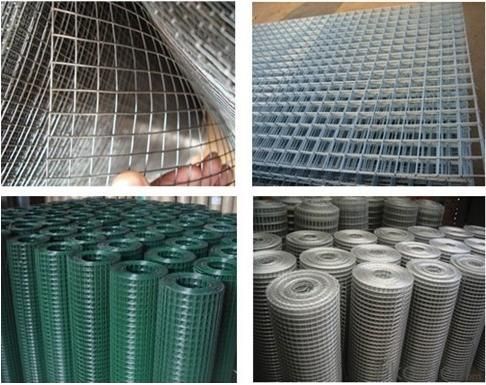

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is steel wire mesh resistant to vibrations or shocks?

- Yes, steel wire mesh is generally resistant to vibrations and shocks due to its high tensile strength and structural stability. It can effectively absorb and distribute the impact force, making it suitable for applications where stability and durability are required.

- Q: How does steel wire mesh perform in terms of durability?

- Steel wire mesh is known for its exceptional durability. It is made from high-quality steel that is strong and resilient, allowing it to withstand various environmental factors and physical stresses. The durability of steel wire mesh makes it suitable for a wide range of applications, including construction, fencing, industrial uses, and even art installations. One of the key factors contributing to the durability of steel wire mesh is its resistance to corrosion. Steel wire mesh is typically galvanized or coated with a protective layer to prevent rust and corrosion. This coating ensures that the mesh retains its strength and integrity even when exposed to moisture, chemicals, and other corrosive elements. Furthermore, steel wire mesh is highly resistant to impact and deformation. Its robust construction allows it to withstand heavy loads, impacts, and pressure without bending or breaking. This makes it an ideal choice for applications that require a strong and durable material, such as reinforcing concrete structures or providing security fencing. In terms of longevity, steel wire mesh has a significantly longer lifespan compared to other materials like plastic or aluminum. It can endure harsh weather conditions, temperature fluctuations, and UV exposure without deteriorating or losing its structural integrity. This longevity translates to cost savings in the long run, as steel wire mesh does not require frequent replacements or repairs. Overall, steel wire mesh is a highly durable material that offers exceptional strength, resistance to corrosion, and longevity. Its ability to withstand various environmental and physical challenges makes it a reliable choice for a wide range of applications where durability is crucial.

- Q: Can steel wire mesh be used for creating sunscreens or shades?

- Yes, steel wire mesh can be used for creating sunscreens or shades. Steel wire mesh is a durable and versatile material that can effectively block sunlight and provide shade. Its open design allows for airflow and visibility while still providing protection from direct sunlight. Steel wire mesh can be used in various applications such as window screens, pergolas, or outdoor structures to create functional and aesthetically pleasing sunscreens or shades. Additionally, steel wire mesh is resistant to corrosion and is able to withstand harsh weather conditions, making it a suitable choice for outdoor use.

- Q: Can steel wire mesh be used for construction?

- Yes, steel wire mesh can be used for construction. It is a versatile material that offers various benefits in construction projects. Steel wire mesh is commonly used for reinforcing concrete structures, such as foundations, walls, and slabs, as it provides added strength and durability. It helps to distribute the load evenly, minimizing cracks and improving the overall structural integrity of the construction. Moreover, steel wire mesh can also be used in construction for other purposes, such as forming partitions, creating fences, and providing security. Its high tensile strength, corrosion resistance, and flexibility make it suitable for various construction applications.

- Q: How does the weaving method affect the overall quality of steel wire mesh?

- The weaving method has a significant impact on the overall quality of steel wire mesh. The choice of weaving method determines the strength, durability, and appearance of the mesh. Different weaving methods, such as plain weave, twill weave, or Dutch weave, offer varying levels of stability, resistance to wear and tear, and filtration capabilities. The weaving method also affects the mesh's ability to withstand heavy loads, corrosion, and maintain its shape over time. Therefore, selecting the appropriate weaving method plays a crucial role in ensuring the desired quality and performance of steel wire mesh.

- Q: What are the different sizes and gauges available for steel wire mesh?

- Steel wire mesh is available in a variety of sizes and gauges to suit different applications and requirements. The sizes of steel wire mesh typically range from small, fine meshes to larger, coarser meshes. The sizes are usually specified by the number of openings per linear inch or by the clear opening size. Common sizes include 2 mesh (2 openings per inch), 4 mesh, 8 mesh, 16 mesh, and 30 mesh, among others. In terms of gauges, steel wire mesh is available in different thicknesses. The gauge of a wire refers to its diameter, with a lower gauge number indicating a thicker wire. Common gauges for steel wire mesh range from 6 gauge (0.192 inches) to 24 gauge (0.0201 inches), with 10 gauge, 12 gauge, and 14 gauge being commonly used. The selection of the appropriate size and gauge of steel wire mesh depends on the specific application. Fine mesh sizes are often used for sifting, filtering, and separating materials, while coarser mesh sizes are suitable for applications such as fencing, reinforcement, and protection. The choice of gauge depends on factors such as the desired strength, durability, and level of visibility required. It is worth noting that these sizes and gauges are standard measurements, but custom sizes and gauges can also be manufactured to meet specific project needs. Overall, the availability of different sizes and gauges allows for flexibility in choosing the most suitable steel wire mesh for a particular application.

- Q: How is steel wire mesh different from other types of wire mesh?

- Steel wire mesh is different from other types of wire mesh primarily because it is made from steel, which gives it enhanced strength, durability, and resistance to corrosion. This makes steel wire mesh the ideal choice for applications that require high tensile strength, such as construction, industrial, and agricultural purposes. Additionally, steel wire mesh is available in various sizes, weaves, and configurations, making it suitable for a wide range of applications and providing versatility that sets it apart from other types of wire mesh.

- Q: How is steel wire mesh used in reinforcement of warehouses?

- Steel wire mesh is commonly used in the reinforcement of warehouses for several reasons. Firstly, it provides structural integrity and strength to the building. The steel wire mesh is typically embedded within the concrete floors and walls of the warehouse, acting as a reinforcement material to enhance the overall durability and load-bearing capacity of the structure. Additionally, steel wire mesh helps to control cracking and prevent the propagation of cracks. As warehouses often experience heavy loads and vibrations from equipment and storage, the steel wire mesh effectively distributes these forces, minimizing the risk of cracks forming and spreading throughout the structure. This ensures the longevity and safety of the warehouse. Moreover, steel wire mesh is beneficial in reinforcing warehouse floors to withstand heavy traffic, such as forklifts and pallet jacks. By adding a layer of steel wire mesh within the concrete slab, the floor becomes more resistant to impact and abrasion, reducing the likelihood of damage and increasing the overall lifespan of the flooring. Furthermore, steel wire mesh is used to reinforce warehouse walls and ceilings to enhance their resistance to lateral forces such as wind or seismic activity. This reinforcement helps to maintain the structural integrity of the warehouse, ensuring the safety of both the building and its contents. In summary, steel wire mesh is an essential component in the reinforcement of warehouses. It provides structural strength, controls cracking, enhances load-bearing capacity, and improves resistance to heavy traffic and external forces. By incorporating steel wire mesh into the construction of warehouses, builders can create durable and reliable structures that can withstand the demands of industrial environments.

- Q: Can steel wire mesh be used for retaining rock walls?

- Yes, steel wire mesh can be used for retaining rock walls. Steel wire mesh is commonly used in various construction applications, including retaining walls. When properly installed, it provides additional support and stability to the rock wall by acting as a reinforcement. The wire mesh helps to prevent the rocks from shifting or sliding, enhancing the overall strength and durability of the wall. Additionally, steel wire mesh is resistant to corrosion, making it a suitable choice for outdoor applications where it may be exposed to moisture and other environmental factors.

Send your message to us

Welded Wire Mesh for Chicken Fence-1 X 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords