Electric Galvanized Hexagonal Wire Netting for Rockwool

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh for Rockwool

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh for Rockwool

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh for Rockwool

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh for Rockwool

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh for Rockwool

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

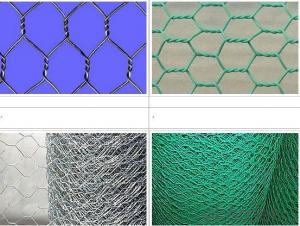

Pictures of Galvanized Hexagonal Wire Mesh for Rockwool

Specification of Galvanized Hexagonal Wire Mesh for Rockwool

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How does the roll size affect the ease of installation of steel wire mesh?

- The roll size of steel wire mesh can affect the ease of installation. Smaller roll sizes are generally easier to handle and maneuver, making them more convenient for installation. They can be easily transported to the desired location and are less likely to get tangled or damaged during the process. On the other hand, larger roll sizes can be more challenging to handle and may require additional manpower or equipment. They may also be more difficult to transport and maneuver into position. Therefore, smaller roll sizes tend to offer greater ease of installation compared to larger ones.

- Q: What are the aesthetic options available for steel wire mesh?

- There are several aesthetic options available for steel wire mesh, allowing for customization and versatility in various applications. One option is the choice of wire diameter. Steel wire mesh can be manufactured using different gauges, ranging from thin to thick wires. Thinner wires create a more delicate and intricate appearance, while thicker wires provide a sturdier and more robust look. Another aesthetic option is the mesh opening size. The spacing between the wires can vary, resulting in different patterns and visual effects. Smaller openings create a more refined and detailed look, while larger openings give a more open and airy feel. The surface finish of the steel wire mesh can also be customized. It can be left untreated for a raw and industrial appearance, or it can be coated with various finishes for added protection and aesthetics. Common finishes include galvanized, which provides corrosion resistance, and powder coating, which offers a wide range of colors and textures. Additionally, steel wire mesh can be woven in different patterns, such as plain weave, twill weave, or Dutch weave. Each pattern creates a distinct visual effect and texture, allowing for further aesthetic customization. Lastly, steel wire mesh can be combined with other materials, such as wood or glass, to create unique and visually appealing designs. This combination of materials adds depth and contrast to the overall aesthetic. In summary, the aesthetic options available for steel wire mesh are numerous. From wire diameter and mesh opening size to surface finish and weaving patterns, these options provide flexibility and allow for customization to suit different design preferences and applications.

- Q: What are the safety precautions for handling steel wire mesh?

- When handling steel wire mesh, there are a few important safety precautions to keep in mind. Firstly, it is essential to wear appropriate personal protective equipment, such as gloves and safety glasses, to prevent any injuries or cuts from the sharp edges of the mesh. Secondly, ensure that the work area is well-lit and free from any obstructions or tripping hazards. It is also advisable to use proper lifting techniques and equipment when moving or lifting heavy rolls or sheets of wire mesh to avoid strains or back injuries. Lastly, be cautious when working with power tools or machinery to avoid accidental contact with the mesh, and always follow the manufacturer's instructions and guidelines for safe operation.

- Q: Is steel wire mesh suitable for use in hydroponic systems?

- Hydroponic systems can benefit from the use of steel wire mesh. This durable and versatile material has various applications. In hydroponics, steel wire mesh serves multiple purposes. One of its main functions is providing support for plants. Steel wire mesh can be used to create trellises or cages, ensuring the proper growth of climbing plants like tomatoes or cucumbers. Its strength and rigidity prevent plant collapse or instability. Steel wire mesh can also serve as a growth medium. By suspending the mesh horizontally, plants can be placed on top, enabling their roots to grow through and access the nutrient-rich water below. This method, known as the "Dutch bucket" or "bato bucket" system, is widely used in hydroponics. Steel wire mesh is an excellent choice due to its strength and resistance to corrosion. Moreover, steel wire mesh can be utilized to make trays or baskets for holding growing media, such as perlite, vermiculite, or coconut coir. These trays or baskets allow the nutrient solution to flow through the mesh, reaching the plant roots and providing essential water and nutrients. In summary, steel wire mesh is a suitable material for hydroponic systems because of its strength, durability, and versatility. It provides plant support, serves as a growth medium, and creates trays or baskets for holding growing media.

- Q: Can steel wire mesh be used for reinforcement?

- Indeed, steel wire mesh finds utility in a multitude of applications as a reinforcement material. In the realm of construction, it is a prevalent choice for fortifying concrete structures, including walls, slabs, and foundations. Its inclusion serves to bolster the concrete, granting it heightened strength and durability, thereby thwarting the likelihood of cracks or fractures occurring when subjected to pressure. In the domain of road and pavement construction, steel wire mesh is harnessed to fortify asphalt, preventing the emergence of cracks. Moreover, it plays a pivotal role in the production of fences, cages, and other industrial implements that necessitate sturdy and enduring features. All in all, steel wire mesh is an efficacious and extensively employed medium for reinforcement purposes.

- Q: How does steel wire mesh perform in load-bearing capacity?

- Steel wire mesh has excellent load-bearing capacity due to its strong and durable nature. It can effectively distribute and bear heavy loads without deforming or breaking, making it suitable for various applications such as construction, reinforcement, and fencing.

- Q: How does steel wire mesh perform in radiation shielding applications?

- Steel wire mesh performs well in radiation shielding applications due to its high density and ability to attenuate radiation. The dense structure of the mesh effectively absorbs and scatters radiation, reducing its intensity and preventing it from passing through the shield. The thickness and composition of the steel wire mesh can be customized to provide the desired level of radiation protection. Additionally, the durability and strength of steel make it suitable for long-term use in harsh environments, ensuring the integrity of the shielding over time. Overall, steel wire mesh is a reliable and effective choice for radiation shielding applications.

- Q: What are the maintenance requirements for steel wire mesh?

- The maintenance requirements for steel wire mesh typically involve regular cleaning to remove any dirt or debris that may accumulate on the surface. Additionally, it is important to inspect the mesh for any signs of damage or corrosion and address them promptly to prevent further deterioration. Periodic lubrication may also be necessary to ensure smooth operation, especially in cases where the mesh is used in a moving or mechanical application.

- Q: Can steel wire mesh be used for sunshade?

- Yes, steel wire mesh can be used for sunshade. It is a durable and strong material that can effectively block sunlight and provide shade in various outdoor settings.

- Q: Can steel wire mesh be used in automotive applications?

- Yes, steel wire mesh can be used in automotive applications. Steel wire mesh is commonly used in automotive manufacturing for various purposes such as reinforcing vehicle body structures, providing protection for radiators and other components, as well as for interior applications like seat frames and headrests. It offers excellent strength, durability, and resistance to impact, making it a suitable material for automotive applications where safety and reliability are crucial. Additionally, steel wire mesh can be easily molded and shaped to fit different automotive parts, providing flexibility in design and assembly.

Send your message to us

Electric Galvanized Hexagonal Wire Netting for Rockwool

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords