Prepainted galvanized corrugated plate / sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

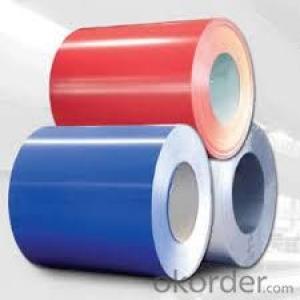

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length,according to the transportation,generally less than 12m

4.color: standard color:red,blue,white,grey; pecial color:according to RAL color

Specification:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length,according to the transportation,generally less than 12m |

color | standard color:red,blue,white,grey |

special color:according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span:more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house,steel house,mobile house,modular house,villa,bungalow design,portable house/carbin,ready made house,kiosk booths,steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts,maufacturing shells of motors and so on | |

packing | plastic film,pallet or as your request |

Images:

- Q: Are steel sheets resistant to termites?

- Steel sheets are not immune to termites, contrary to materials like concrete or steel. Termites can effortlessly invade steel sheets and devour the wood framing or any organic substances that might be there. Thus, it is crucial to implement necessary precautions to safeguard steel sheets from termite infestation. These measures may include utilizing termite barriers, treating the adjacent soil, or routinely examining and upkeeping the region to deter termite intrusion and destruction.

- Q: What are the different methods of cleaning steel sheets?

- There are several methods of cleaning steel sheets, including mechanical methods such as scrubbing or sanding, chemical methods like using solvents or detergents, and thermal methods like heat treating or flame cleaning.

- Q: Can steel sheets be used for HVAC applications?

- Yes, steel sheets can be used for HVAC applications. Steel is a common material used in HVAC systems due to its strength, durability, and heat resistance. It is often used for ductwork, air handling units, and other components of HVAC systems.

- Q: What material is steel plate against drilling?

- There is also an ordinary steel sheet drilling method: steel plate carburizing, quenching treatment, to achieve high hardness.

- Q: Stainless steel plate how to cast mirror plate?

- Stainless steel hot rolled plate mirror polishing (mirror, polishing)In recent years, more and more requirements for polishing of stainless steel hot rolled plate, and even mirror polishing have been demanded. The treatment of hot rolled plate is quite different from that of cold rolled plate, and the whole process is more complicated and difficult to handle than cold rolled plate.

- Q: The difference between steel edge sealing strip and steel plate putty water stop belt

- The steel sealing strip is made of pure steel plate and can be divided into galvanized steel sheet, ordinary steel plate and stainless steel water stop belt.

- Q: What are the different grades of steel used for sheets?

- The different grades of steel used for sheets vary depending on factors such as strength, durability, and corrosion resistance. Some common grades include carbon steel (e.g., A36), stainless steel (e.g., 304 or 316), and high-strength low-alloy steel (e.g., A572). Each grade has specific properties that make it suitable for various applications in industries like construction, automotive, and manufacturing.

- Q: Can steel sheets be used in corrosive chemical environments?

- Steel sheets can be used in corrosive chemical environments, but their resistance to corrosion will depend on the specific type of steel and the nature of the chemicals present. Stainless steel sheets, for example, are known for their excellent corrosion resistance and are commonly used in such environments. However, it is important to consider the concentration, temperature, and duration of exposure to the corrosive chemicals to determine the suitability of steel sheets for a specific application. Additional protective measures like coatings or alloys may also be necessary to enhance the corrosion resistance of steel sheets in highly corrosive chemical environments.

- Q: Can steel sheets be recycled after use?

- Yes, steel sheets can be recycled after use. Steel is a highly recyclable material, and recycling steel sheets helps to conserve energy and reduce the need for raw materials in steel production.

- Q: Are steel sheets resistant to staining or discoloration?

- Yes, steel sheets are generally resistant to staining or discoloration due to their nonporous nature and protective coatings.

Send your message to us

Prepainted galvanized corrugated plate / sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords