Prepainted Galvalnized Steel Coils for Corrugated Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Surface Treatment:Coated

Technique:Cold Rolled

Standard:JIS

Type:Steel Coil

Special Use:High-Strength Steel Plate

Application:Building Material, Roofing, Household Appliance, E

Export Markets:Global

Additional Info.

Packing:Standard Export and Seaworthy Packing

Standard:GB/T12754, JIS3312, EN 10169 ASTM A755

Origin:China

Product Description

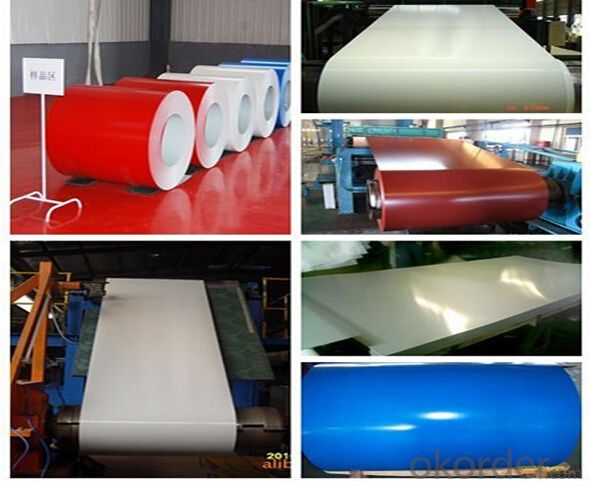

Color coated Prepainted Galvanized Steel Coils

Grade: SGCC, DX51D, CGCC

Thick: 0.17-0.8, Width: 58-1250mm

Coat: PE, SMP, HDP, PVDF

PPGI PPGL Prepainted Steel coil:

Color coated Prepainted galvanized Steel Coils

Certificate: ISO 9001/14001

The main specification is as belows:

Standards: GB/T12754, JIS3312, EN 10169 ASTM A755

Thickness: 0.14-0.8mm; Width: 914-1250mm

Tolerance: +2/0mm, thickness tolerance: +0.02/-0.02mm (or according to customers' request).

Coating mass: Top; 13-25, Back: 5-10

Coil weight: 5-8 metric tons

Coil DM: I. D: Φ 508m/610mm O. D: Max Φ 1500mm

Coating type: PE, SMP, HDP, PVDF

Common performance of front coating:

(1). Thickness: ≥ 20μ M

(2). Pencil Hardness: 2H

(3). 60° Specular glossiness of coating: >60

(4). 180° Bend: ≤ 3T

(5). Impact: ≥ 9J

(6). Salt Fog Resistant: ≥ 500h

(7). Color difference:<3Δ E

Application :

1. Construction: (Outside) workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door

(Inside) door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter

2. Electrical appliance: Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

3. Furniture: Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf

4. Carrying trade: Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board

5. Others: Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment

Specification:

| NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

| CERTIFICATE | ISO9001 | ||

| STANDARD | GB/T-12754 JIS G 3312 EN 10169 ASTM A755 | GB/T-2518 JIS G 3302 EN 10142/10427 ASTM A653 | GB/T-14798 JIS G 3321 EN 10215 ASTM A792 |

| GRADE | SGCC DX51D SGCH CGCD1-CGCD3 CGC340-CGC570 GRADE | SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

| MODEL NO | 0.16MM-1.0MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc |

| SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating | |

| APPLICATION | Structural use ,roofing, corrugated roofing, commercial use, household appliance, industry, family | ||

| SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: All the steel straps that secure my deck and stair 6x6 posts to the concrete piers have some rust on them. Had bought a rust reducer to spray on them and repaint. As I went to do this I found that one of them is on its last legs, with the steel rusted through and bubbling up all up the sides of the straps. Since this is the end post on a row of 3 deck support posts, I was thinking of removing as much rust as possible, then paint with Rustoleum and cover lower post with something to keep water away from post and pier in the future? Was thinking of something removeable so I could check on it for further rusting. What do you folks with building experience think of this? Thanks.

- If these steel straps are rusting through and on their last legs, a coat of paint is going to be cosmetic at best. Replace these straps with new ones. The originals were either very poorly galvanized, or you live someplace with a very corrosive environment. In any event, paint can't save this sort of thing. Steel brackets serve a real purpose, and after they're weakened, they can't do that anymore. How would your home hold up in an earthquake, for example? What you're proposing doesn't sound safe.

- Q: What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel products across various sectors such as construction, automotive, and infrastructure is contributing to the growth of the industry. Steel coils are widely used in these sectors for manufacturing various products such as automobiles, buildings, bridges, and pipelines. Secondly, rapid industrialization and urbanization in emerging economies are fueling the growth of the steel coil industry. Countries like China, India, and Brazil are witnessing significant infrastructure development and construction activities, which require a large amount of steel coils for various applications. Additionally, technological advancements in the manufacturing process and the use of advanced steel alloys are driving the growth of the industry. These advancements have led to the production of high-quality steel coils that offer better strength, durability, and corrosion resistance. Moreover, the growing focus on sustainable and eco-friendly practices is also driving the growth of the steel coil industry. Steel is a highly recyclable material, and the increasing awareness about the environmental benefits of using steel is boosting its demand. Furthermore, favorable government policies and initiatives to promote domestic steel production and reduce imports are also contributing to the growth of the industry. Governments are implementing measures such as import tariffs and subsidies to support local steel manufacturers, which is driving the demand for steel coils. In conclusion, the factors driving the growth of the steel coil industry include increasing demand from various sectors, rapid industrialization, technological advancements, environmental awareness, and supportive government policies.

- Q: What are the different types of corrosion protection methods used for steel coils?

- There are several types of corrosion protection methods used for steel coils, including: 1. Coating: Applying a protective layer of paint or coating, such as epoxy or zinc, on the surface of the steel coil to prevent direct contact with moisture and corrosive substances. 2. Galvanization: Immersing the steel coil in a bath of molten zinc to create a protective zinc coating, which acts as a sacrificial layer that corrodes first before the steel. 3. VCI (Volatile Corrosion Inhibitors): Using volatile chemicals that release protective vapors, which form a thin layer on the steel coil's surface, inhibiting corrosion by blocking moisture and oxygen. 4. Passivation: Treating the steel coil with chemicals like nitric acid to remove impurities, creating a passive oxide layer that protects against corrosion. 5. Cathodic Protection: Connecting the steel coil to a sacrificial anode (usually made of zinc or magnesium) or using impressed current to provide a flow of electrons, which prevents corrosion by making the steel coil the cathode in an electrochemical cell. 6. Environmental Control: Maintaining controlled temperature, humidity, and atmospheric conditions during storage and transportation to minimize exposure to corrosive elements. These methods can be used individually or in combination, depending on the specific requirements and environmental conditions.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several different types of steel coil surface treatments that are used to enhance corrosion resistance. These treatments are applied to the surface of the steel coil to create a protective layer that prevents corrosion and extends the lifespan of the steel. Some of the common types of surface treatments for corrosion resistance include: 1. Galvanizing: This is one of the most popular and effective methods for protecting steel against corrosion. In this process, a layer of zinc is applied to the surface of the steel coil. The zinc acts as a sacrificial anode, corroding before the steel does, thus protecting it from rust and corrosion. 2. Chromate conversion coating: This treatment involves applying a chromate-based solution to the surface of the steel coil. The chromate forms a thin film on the steel, providing a protective barrier against corrosion. It also enhances the adhesion of paint or other coatings that may be applied later. 3. Phosphating: Phosphating is a process where a phosphate coating is applied to the steel coil. This coating provides excellent corrosion resistance by forming a chemical bond with the steel surface. It also improves the adhesion of subsequent coatings or paints. 4. Organic coatings: These coatings, such as paint or epoxy, are applied to the steel coil to create a barrier between the steel and the surrounding environment. They provide both corrosion resistance and aesthetic appeal. The choice of organic coating depends on the specific application and the desired level of corrosion protection. 5. Zinc-rich paint: Similar to galvanizing, zinc-rich paint contains a high concentration of zinc particles. When applied to the steel coil, the zinc particles provide sacrificial protection, preventing corrosion. This coating is often used in harsh environments or for steel coils that will be exposed to frequent moisture or saltwater. It is important to note that the choice of surface treatment depends on various factors such as the application, environment, budget, and required level of corrosion resistance. Consulting with a steel coil manufacturer or corrosion specialist is recommended to determine the most suitable treatment for a specific situation.

- Q: which pokemon has the most steel pokemon???

- Probaly Pokemon Platinum or Pokemon HGSS

- Q: What are the different methods of shearing steel coils?

- There exist various approaches to shearing steel coils, each with its own unique pros and cons. Some of the most prevalent methods include: 1. Guillotine Shearing: This technique involves the use of a guillotine-like machine that vertically moves a blade to slice through the steel coil. Guillotine shearing provides high efficiency and accuracy, making it suitable for large-scale industrial production. However, it can lead to deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is employed to cut through the steel coil. This method enables continuous cutting, making it ideal for high-speed production lines. It ensures a clean and precise cut, but necessitates regular maintenance and blade sharpening. 3. Slitting: Slitting entails passing the steel coil through circular blades that create multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers great precision and the ability to generate multiple strips simultaneously. However, slitting may result in edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the steel coil along a predetermined path. This method offers exceptional precision and can cut intricate shapes or patterns. It is commonly employed for specialized applications where accuracy is crucial, although it can be relatively costly. 5. Waterjet Cutting: Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, making it suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM employs electrical discharges to erode the steel coil and achieve the desired shape. This method is commonly used for intricate or delicate cutting tasks that demand high precision. It is particularly effective for hard materials. Each method of shearing steel coils possesses its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: is broken steel the only fallout dlc that will raise the level cap from 20 to 30? also do i have to complete the main quest to play it? which fallout dlc do you think would be the best to get?

- Yes, Broken Steel is the only DLC that raises your level cap. Yes, you have to complete the main quest to play it. It's kind of a prologue to the events of the ending. If you don't have the DLC and complete the game it just ends and you can't play it anymore. With the DLC you'll be able to continue playing. As for which one to get, that's your preference. Most people like the Broken Steel because it has to do with the main story and it raises the level cap - so that's the one I'll suggest to you. I also think The Pitt and Point Lookout are worth getting as well. Mothership Zeta is the one I liked least. I thought it was kind of stupid, to be honest. Operation Anchoarge is a simulation and it's pretty fun, but I don't think it's worth the $9.99.

- Q: who, when and where was dual phase steel invented?

- Looking okorder /... but I would note that this stuff seems an awful lot like the techniques that have been used for making high quality swords and cutting tools for thousands of years including the famed Damacas steel. In these, the steel is heated and slowly cooled (annealed) to produce the tough matrix, then the piece is reheated and quenched to produce the hard edge. What Dual-phase seems to do is bring the process to bulk manufacture.

- Q: What are the different types of steel coil edge conditions?

- There are several different types of steel coil edge conditions, each designed to meet specific requirements and applications. The most common types include: 1. Mill Edge: Mill edge is the default edge condition for hot-rolled steel coils, where the edges are left as they come out of the rolling process. This edge condition is characterized by a slightly rough and uneven surface. 2. Slit Edge: Slit edge is created by cutting the coil along its width to achieve narrower strips. This edge condition is typically smoother and more uniform than mill edge, making it suitable for applications where a clean and precise edge is required. 3. Trimmed Edge: Trimmed edge is achieved by removing irregularities and imperfections from the edges of the coil. This process results in a straight and smooth edge, making it suitable for applications where a precise and uniform surface is necessary. 4. Deburred Edge: Deburred edge is created by removing burrs or sharp edges from the coil. This edge condition is commonly used in applications where safety is a concern, as it eliminates any potential hazards associated with sharp edges. 5. Round Edge: Round edge is achieved by rounding the corners of the coil. This edge condition is often employed in applications where the material needs to be easily handled or when there is a need to prevent damage to other materials or surfaces. 6. Slit and Deburred Edge: Slit and deburred edge combines the benefits of both slit edge and deburred edge conditions. It involves cutting the coil to achieve narrower strips and then removing any burrs or sharp edges, resulting in a clean and safe edge. Each of these edge conditions serves a specific purpose and is chosen based on the requirements of the application. By understanding the different types of steel coil edge conditions, one can select the most suitable option to ensure optimal performance and safety.

- Q: What is the average lead time for receiving replacement steel coils?

- The average lead time for receiving replacement steel coils can vary depending on various factors such as the supplier, location, and specific requirements. It is recommended to contact the supplier directly for an accurate estimation of the lead time.

Send your message to us

Prepainted Galvalnized Steel Coils for Corrugated Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords