Pre-Galvanized Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

![]()

- Q: Can steel pipes be used for water wells?

- Yes, steel pipes can be used for water wells. Steel pipes are commonly used in water well construction due to their durability, strength, and resistance to corrosion. They provide a reliable and long-lasting solution for extracting and transporting water from underground sources.

- Q: How to establish a concrete-filled steel tubular column model in ANSYS?

- First, you have to choose at least three or more types of materials. Modeling is a little complicated. Strongly recommended that the landlord to see "ANSYS in civil engineering applications", where there is such an example, you step by step, step by step back, and then in accordance with their own requirements modeling, OK. Wish you success

- Q: What are the different methods of cleaning steel pipes?

- There are several methods of cleaning steel pipes, including mechanical cleaning, chemical cleaning, and high-pressure water jetting. Mechanical cleaning involves the use of brushes, scrapers, or other abrasive tools to remove dirt and debris from the pipe's surface. Chemical cleaning involves the application of solvents or acids to dissolve tough stains or residues. High-pressure water jetting uses a powerful stream of water to dislodge and remove contaminants from the pipe. These methods can be used individually or in combination depending on the specific cleaning requirements.

- Q: How can steel pipes be protected from corrosion?

- Steel pipes can be protected from corrosion through various methods. One common method is the application of protective coatings. These coatings act as a barrier between the steel and corrosive elements in the environment. The most widely used protective coating for steel pipes is epoxy, which provides excellent resistance to corrosion. Other coatings such as polyethylene and polyurethane can also be used depending on the specific application and requirements. Another effective way to protect steel pipes from corrosion is by cathodic protection. This technique involves the use of sacrificial anodes or impressed current systems to prevent corrosion. Sacrificial anodes, typically made of zinc or aluminum, are attached to the steel pipes. These anodes corrode instead of the steel, sacrificing themselves to protect the pipes. Impressed current systems, on the other hand, use a direct electrical current to counteract the corrosion process. Regular maintenance and inspection are crucial in the protection of steel pipes from corrosion. Monitoring the condition of the coatings, checking for any signs of damage or deterioration, and promptly addressing any issues can help prevent corrosion from occurring or spreading. Additionally, implementing proper drainage systems to avoid the accumulation of moisture around the pipes can further protect them from corrosion. Lastly, environmental factors should be taken into consideration when protecting steel pipes from corrosion. This includes mitigating exposure to corrosive substances, such as acids or chemicals, and ensuring proper ventilation and airflow to prevent the buildup of moisture and humidity. By implementing a combination of these protective measures, steel pipes can have an extended lifespan and maintain their structural integrity.

- Q: What are the different standards for steel pipe manufacturing?

- There are several standards for steel pipe manufacturing, including ASTM (American Society for Testing and Materials), API (American Petroleum Institute), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). These standards define the specifications for various aspects of steel pipe production, such as dimensions, material composition, mechanical properties, and testing procedures. Compliance with these standards ensures the quality and reliability of steel pipes for different applications, ranging from construction and infrastructure to oil and gas industries.

- Q: Can steel pipes be used for solar energy systems?

- Yes, steel pipes can be used for solar energy systems. Steel pipes are commonly used for the construction of solar water heating systems and solar thermal collectors. They are durable, resistant to corrosion, and can efficiently transport hot water or heat transfer fluids, making them suitable for various solar energy applications.

- Q: What's the difference between the fastener type steel pipe scaffold, the floor type steel pipe scaffold and the overhanging type steel pipe scaffold?

- Classification is not the only way, fastener type steel pipe scaffolding is divided by force, and the latter 2 are classified according to the structure.

- Q: What's wrong with the 3PP anticorrosive steel tube?

- At present, mainly foreign related products come out, for some countries with relatively high ambient temperature, and PP than PE to hard, so as to avoid scratching coating.

- Q: What are the different types of steel pipe elbows?

- There are several different types of steel pipe elbows that are commonly used in various industries and applications. These types include: 1. 90-degree elbows: These elbows have a sharp 90-degree bend and are commonly used when a change in direction is required to redirect the flow of fluid or gas. They are widely used in plumbing, construction, and industrial piping systems. 2. 45-degree elbows: Similar to 90-degree elbows, 45-degree elbows also provide a change in direction but with a smaller angle. They are often used in situations where a more gradual change in flow direction is required. 3. Long radius elbows: Long radius elbows have a larger radius of curvature compared to standard elbows. This design helps to reduce fluid friction and pressure drop, making them suitable for applications that require smoother flow, such as in high-flow systems or those involving viscous fluids. 4. Short radius elbows: In contrast to long radius elbows, short radius elbows have a smaller radius of curvature. They are generally used in tight spaces where a compact design is required, but they can cause higher pressure drops due to increased fluid friction. 5. Reducing elbows: These elbows are used when there is a need to connect pipes of different diameters. They have one end with a larger diameter and the other end with a smaller diameter, allowing for a smooth transition between two pipes of different sizes. 6. Mitered elbows: Mitered elbows are custom-made elbows that are fabricated by cutting and welding multiple sections of pipe at specific angles. They are often used in situations where standard elbows cannot accommodate the required angle or when a unique design is needed. Overall, the selection of the appropriate type of steel pipe elbow depends on factors such as the application, fluid flow requirements, space constraints, and compatibility with the piping system.

- Q: Can steel pipes be used for the construction of dams?

- Yes, steel pipes can be used for the construction of dams. Steel pipes are often used in dam construction for various purposes such as water intake and outlet structures, penstocks, and spillway gates. They offer durability, strength, and resistance to corrosion, making them suitable for withstanding the high pressures and harsh environments associated with dam construction.

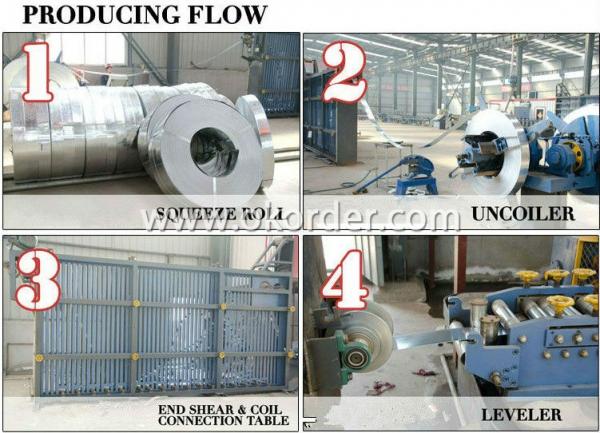

The main production and sale of galvanized steel, the thin-walled high-frequency welded pipe, galvanized pipe, square pipe, rectangular pipe, conduit, EMT conduit, greenhouse pipes, galvanized pipes, and other related products, annual production capacity of 40,000 tons. The company has independent export rights.

1. Manufacturer Overview

| Location | Tianjin ,China |

| Year Established | 2004 |

| Annual Output Value | Above 100milion rmb |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 38000squar meter |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Pre-Galvanized Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords