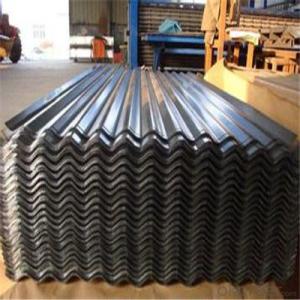

Galvanized Corrugated Steel for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:CUS-140527-K

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q235

Surface Treatment:Galvanized

Technique:Cold Rolled

Thickness:0.12-1.5mm

Zinc Coating:40-275G/M2

Surface Structure:Ero Spangle, Regular Spangle or Normal Spangle

Width:600-1250mm

Material:SGCC,Sgcd,Secc,Secd,Dx51d+Z

Export Markets:Global

Additional Info.

Packing:Export Packing

Standard:ISO9001/SGS/BV

Origin:Henan, China

HS Code:7210

Production Capacity:300000 Mt/Year

Product Description

Specifications:

1. Thickness: 0.12-1.5mm

2. Width: 600-1250mm

3. Material: SGCC, SGCD, SECC, SECD, DX51D+Z

4. Zinc coating: 40-275G/M2

5. Surface Structure: Galvanized, zero spangle, regular spangle or normal spangle

6. Surface treatment: Chromated and oiled, chromated and non-oiled

Main characteristics:

1. Strong corrosion resistance

2. Surface quality

3. Conducive to deep processing, such as corrugated steel sheet 4. Economy and practicality

Packing

Each bare coil to be securely tied with two bands through the eye of coil (or not) and one circumferential, the contact points of these bands on the coil edge to be protect with edge protectors. Coil then to be properly wrapped with water proof /resistant paper, it then to be properly and completely metal wrapped. And each packed coil to be properly wrapped with band, three-six such band through the eye of coil at about equal distance, and two-four such bands securely tied around belly of coil at about equal distance.

| Commodity | Hot dip galvanized steel coil and sheet |

| Techinical Standard: | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-1.5mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20''containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| delivery time | 25 days after recepit of 30% TT |

| Remarks | Insurance is as requirements |

| MTC will be handed on with shipping documents | |

| We accept the third party certification test |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What is the lifespan of steel coils?

- The lifespan of steel coils can vary depending on various factors such as the quality of the steel, the conditions in which they are stored or used, and the maintenance practices employed. However, with proper care and maintenance, steel coils can last for several decades or even longer.

- Q: What are the common methods of packaging steel coils for transportation?

- There are several common methods of packaging steel coils for transportation. One widely used method is to use steel strapping or bands to secure the coils together. This method involves tightly wrapping the coils with steel bands and securing them with metal buckles or seals. The strapping helps to keep the coils in place and prevents them from shifting or rolling during transportation. Another common method is to use wooden pallets or skids to stack and transport the steel coils. The coils are placed on the pallets and secured with steel strapping or bands. This method provides stability and allows for easy handling and loading onto trucks or other transportation vehicles. Some steel coils are also packaged in wooden crates or boxes. These crates are typically made of strong and durable wood and are designed to protect the coils from external impacts or damage during transportation. The crates are often reinforced with steel bands or strapping to provide additional strength and stability. In addition to these methods, some steel coils are packaged in specialized containers or units. These containers are specifically designed to hold and secure steel coils for transportation. They often have built-in mechanisms or features that make loading and unloading the coils easier and safer. It is important to note that the specific method of packaging steel coils for transportation may vary depending on factors such as the size and weight of the coils, the mode of transportation, and any specific requirements or regulations in place.

- Q: Can steel coils be coated with organic materials?

- Yes, steel coils can be coated with organic materials.

- Q: What are the dimensions of a steel coil?

- The dimensions of a steel coil can vary depending on several factors such as the intended use, manufacturer specifications, and industry standards. However, common dimensions for steel coils typically include variations in width, thickness, and weight.

- Q: How are steel coils used in the production of steel locks?

- Steel coils are used in the production of steel locks as they are rolled into sheets and then cut into appropriate sizes to form the body and components of the locks. The coils provide a consistent and high-quality raw material that can be easily shaped and transformed into the desired lock designs, ensuring durability and strength in the final product.

- Q: During fatigue testing of any material (especially for steels), why is strain-control mode preferred over stress control mode?

- because metals, like steel, are ductile and will stretch before breaking. Straining the metal is stretching it, stressing the metal is applying a shearing force or bending until there is an actual metal failure. A sheet metal strap 1inch across and 24 gauge metal is commonly used to support metal ducting systems in construction. These have an average strain to failure weight load as high as 16,200 lbs. As reported by the smacna index, they will safely hold 6800 pounds. Of more interest is the screws used to hold the strap to the duct. While they are grade 3, fairly strong, they strain to 1400 pounds when properly installed, and are safely able to support 650 pounds, unless they are overtorqued (stripped) and this quickly drops to 400 pounds and 125 pounds...big difference.

- Q: please i need your help in answering this question manufacturing process of steel containers and 20 references

- There are many types of steel containers and many different mnfg processes. There are also thousands of different steel alloys. Steel is used for canned food, compressed air cyclinders, hydraulic pressure vessels, electrical boxes, and many other containers. Steel containers are made out of sheet metal by soldering, brazing, spot welding, seam welding, riveting, bolting, screwing, etc. Heavier wall containers are fabricated of plate steel. Some steel containers are made by deforming the steel by extruding, forging, spin forming, drawing, ironing, etc. Some steel containers are made by machining. You should be able to find plenty of references if you search for these terms. good luck

- Q: How is it used easy 10 points just tell me how its used or any intersting facts this is for my comp science paper lol. I know what the hell does steel have to too do with computers he is a Fg! Please be descriptive THANKS! FAST ANSWERS TOO it 9pm bedtime for a 14 year old lol..

- steel is used for cars and trains. one of the largest steel manufacturers is in my town its called CarTech its in reading pa.

- Q: Hey I just got a mini 14 manufactured in 1980. I also had some .223 Wolf steel cased HP rounds (about 200) that i could shoot throught it, but I was just wondering if its a bad idea to use this steel cased ammo...? Only the casing is steel i believe... and the bullet is copper jacketedthanks for your help

- I have used wolf steel cased ammunition as well when I borrowed my friend's AR-15. It's good ammunition and I personally have not experienced a stovepipe or a jam with the ammunition. A Mini 14 is a great .223 civilian rifle made by Ruger and should not jam with the ammunition. If the polymer coating really is a problem sometimes, just don't use it with knockoff AR-15s or Mini-14s but stick with the major manufacturers.

- Q: I'm quite confused...i watched all of steel angel kurumi (the 28 episodes) and then continued to steel angel kurumi zero. it was an entire different story line with only the steel angels being the same. the world is different the guys are different, and there is a new character. Even the humor is gone. its like a whole different series. So what gives, what is the relationship between them?

- Steel Angel Zero is an OVA (Original Video Animation), a very short animation that went straight to DVD. It probably was written because Kurumi was so popular, and the producer wanted to check the waters for whether they should make a second season. It's pretty hard to keep track of what anime is which, especially in the more popular series. If you think Zero is worth zero, try Steel Angel Kurumi 2 (anime, 12 episodes), and Steel Angel Kurumi Encore (OVA, 4 episodes) as well.

Send your message to us

Galvanized Corrugated Steel for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords