Galvanized Corrugated Iron Sheet for Roofing Supplied in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Minimum yield strength of 550 MPa ensures required strength for roofing application

Accurate thickness, width and length gives a perfect fit for any roof

Wider valley ensures higher water discharge in case of heavy rains

Specifications of Corrugated Iron Sheet:

Corrugated board, also called pressure plate, with color coated steel, galvanized sheet metal plate by roll cold-formed into a variety of wave pressure plate, which is suitable for industrial and civil buildings, warehouse, special construction, large span steel house roof, walls and interior and exterior decoration. Has many characteristics such as light weight, high strength, rich luster, convenient construction, earthquake, fire prevention, waterproof, long service life, maintenance free, etc., has been widely applied.

Features of Corrugated Iron Sheet:

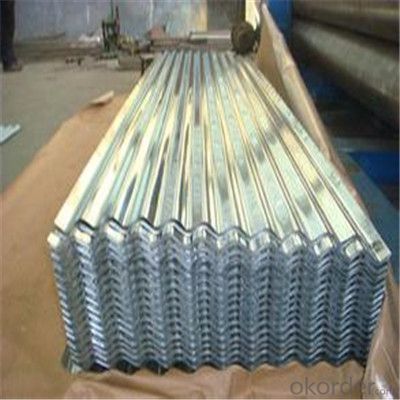

Raw material width 762mm, after corrugated width 665mm: 9 waves.

Raw material width 914mm ,after corrugated width 800mm:11 waves.

Raw material width 1000mm, after corrugated 890mm or 900mm :12 or 14 waves. as customer requirement

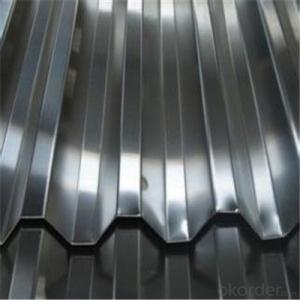

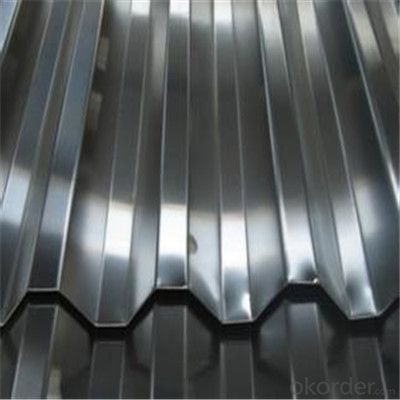

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the different types of steel sheet finishes for decorative purposes?

- For decorative purposes, one can find several varieties of steel sheet finishes that are commonly utilized. These finishes are applied to the steel sheet's surface with the intention of enhancing its appearance and achieving a desired aesthetic effect. Some of the most favored finishes for decorative purposes are as follows: 1. Brushed Finish: Achieved by brushing the steel sheet's surface with a fine abrasive material, usually in a straight line pattern, this finish imparts a smooth and satin-like appearance. It is widely used in architectural and interior design applications. 2. Mirror Finish: Also known as a polished finish, this type creates a highly reflective surface that resembles a mirror. The steel sheet is mechanically polished to achieve this finish, and it is commonly seen in decorative applications such as furniture, lighting fixtures, and signage. 3. Patterned Finish: This finish involves embossing or etching a pattern onto the steel sheet's surface. It can be achieved through various techniques like stamping, laser engraving, or chemical etching. Patterned finishes provide a decorative and textured appearance and are often used in applications like elevator panels, wall cladding, and decorative screens. 4. Colored Finish: To add vibrancy and enhance visual appeal, steel sheets can be coated with a colored finish. Processes such as powder coating are employed, where a dry powder is applied to the steel sheet and then cured to create a durable, colored finish. Colored finishes are commonly used in architectural applications like building facades and signage. 5. Antique Finish: This particular finish is designed to give the steel sheet an aged or weathered look, resembling antique metal. Various techniques such as chemical treatments, patinas, or distressing can be employed to achieve this appearance. Antique finishes are often utilized in decorative applications to create a rustic or vintage aesthetic. These are just a few examples of the diverse range of steel sheet finishes available for decorative purposes. Each finish provides a distinct appearance and can be customized to suit specific design preferences. The choice of finish relies on factors such as the desired look, application, and required level of durability for the project.

- Q: Can steel sheets be used as a decorative material?

- Yes, steel sheets can be used as a decorative material. With its sleek and modern appearance, steel sheets can add a contemporary touch to various applications, such as interior and exterior design, furniture, wall panels, and more. Additionally, steel sheets offer durability, versatility, and low maintenance, making them a popular choice for decorative purposes.

- Q: What are the different methods of surface cleaning for steel sheets?

- Surface cleaning of steel sheets offers various methods, each with its own advantages and applications. 1. Mechanical Cleaning: To physically eliminate dirt, rust, and other contaminants from steel sheet surfaces, one can utilize sandpaper, wire brushes, or abrasive blasting. This approach is ideal for heavy-duty cleaning and preparing surfaces for further treatment or coating. 2. Chemical Cleaning: By employing chemicals or detergents, one can dissolve or remove contaminants from the steel surface. This method is particularly effective in eliminating grease, oil, and other organic substances. It is crucial to select the appropriate chemical cleaner based on the type of contamination and the composition of the steel sheet, ensuring effective cleaning without surface damage. 3. Electrolytic Cleaning: This technique involves submerging the steel sheet in an electrolyte bath along with an electric current to dissolve and separate contaminants. Electrolytic cleaning is effective in removing stubborn rust, scale, and oxidation, while also providing a polished finish. 4. Power Washing: Also known as pressure washing, this method employs a high-pressure water stream to cleanse the steel surface. Power washing effectively removes loose debris, dirt, and mild contaminants. However, it may not be suitable for heavy-duty cleaning or the elimination of stubborn substances like rust. 5. Vapor Degreasing: Vapor degreasing utilizes solvent vapors to clean the steel surface. By exposing the steel sheet to these vapors, contaminants are dissolved and removed. This technique is particularly effective in eliminating oil, grease, and other organic substances. Vapor degreasing is a precise and controlled cleaning method commonly utilized in industrial applications. Before selecting a surface cleaning method, it is crucial to consider the type and severity of contamination, the desired level of cleaning, and the specific requirements of the steel sheets. Additionally, it is important to prioritize safety precautions and utilize appropriate protective equipment when performing any surface cleaning procedure.

- Q: How long do steel sheets typically last?

- Steel sheets typically have a long lifespan and can last anywhere from 20 to 50 years, depending on factors such as maintenance, exposure to harsh conditions, and quality of the steel.

- Q: Can steel sheets be used in marine environments?

- Yes, steel sheets can be used in marine environments. However, it is important to use corrosion-resistant steel grades or apply protective coatings to prevent rusting and degradation caused by exposure to saltwater and other harsh marine conditions.

- Q: Can steel sheets be used for manufacturing storage racks or shelves?

- Yes, steel sheets can be used for manufacturing storage racks or shelves. Steel is a durable and strong material that can withstand heavy loads, making it suitable for constructing storage racks or shelves that need to support various items. Additionally, steel sheets can be easily shaped and customized to accommodate different sizes and designs, making them highly versatile for manufacturing storage solutions.

- Q: Can steel sheets be used for manufacturing musical instruments?

- Yes, steel sheets can be used for manufacturing certain musical instruments such as steel drums, steel guitars, and some percussion instruments.

- Q: What's the difference between single rolling steel sheet and continuous rolling steel plate?

- Single rolled steel plate usually refers to medium plate, in the process of rolling and finishing, the plate has been flat, usually thicker (6mm or more), the width of the fastest up to 4800mm.

- Q: Can steel sheets be used for staircase railings?

- Yes, steel sheets can be used for staircase railings. Steel is a strong and durable material that can provide stability and safety to staircase railings. It can be shaped and designed to create various styles and patterns, making it a versatile choice for railings.

- Q: What are the different sheet metal joining techniques for steel sheets?

- There are several sheet metal joining techniques that can be used for steel sheets. Some of the most common ones include: 1. Welding: Welding is a popular and widely used technique for joining steel sheets. It involves melting the edges of the sheets and fusing them together using heat and pressure. Different types of welding techniques can be employed, such as arc welding, spot welding, or laser welding, depending on the specific application and requirements. 2. Riveting: Riveting is a fastening method where metal fasteners called rivets are used to hold the sheets together. It involves drilling holes in the sheets and inserting the rivets, which are then deformed to secure the joint. This technique provides strong and durable connections, making it suitable for structural applications. 3. Bolting: Bolting involves using bolts and nuts to connect steel sheets. Holes are drilled in the sheets, and bolts are inserted through the holes, with nuts tightened on the other side to hold the joint in place. Bolting offers the advantage of easy disassembly and reassembly, making it suitable for applications where frequent maintenance or repairs are required. 4. Adhesive bonding: Adhesive bonding is a technique where a strong adhesive or glue is used to bond steel sheets together. The adhesive is applied between the surfaces to be joined, and then pressure is applied to ensure proper bonding. Adhesive bonding provides a clean and aesthetically pleasing joint, without the need for drilling holes or using fasteners. 5. Clinching: Clinching is a cold joining technique that involves deforming the sheets to create a mechanical interlock. It is achieved by pressing the sheets together using a punch and die, which forms a raised feature on one sheet that interlocks with a depression on the other sheet. Clinching is a cost-effective and quick method for joining steel sheets without the need for additional materials. Each of these joining techniques has its own advantages and limitations, and the choice of technique depends on factors such as the specific application, required strength, durability, cost, and ease of assembly.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Supplied in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords