GALVANIZED AIRCRAFT CABLE 6X7. RR-W-410D

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Steel Grade:Carbon Steel

Standard:ASTM

Wire Gauge:1/4"-3/4"

Place of Origin:Chongqing, China (Mainland)

Type:Galvanized

Application:for bearing to tank and cableway

Alloy Or Not:Non-alloy

Special Use:Cold Heading Steel

Model Number:CHWR6*7101121

Packaging & Delivery

| Packaging Details: | Wooden Reels or as per your request. |

|---|---|

| Delivery Detail: | 35days. |

Specifications

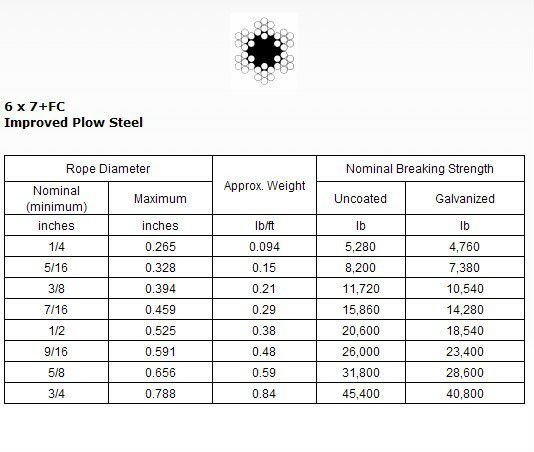

GALVANIZED AIRCRAFT CABLE 6X7. RR-W-410D

Nominal Diameter: 1/4" to 3/4"

ISO9001:2008 Cert.

GALVANIZED AIRCRAFT CABLE

Galvanized Aircraft Cable is made in accordance with Federal Specification RR-W-410D,

meeting the dimensional and strength requirements

requirements of MIL-W-83420D.

Delivery time: 35days for 1x20'container.

- Q: I'm trying to use a stereo wire instead of a mono wire for an output from a circuit I've built. The problem is, the gold wire has been cut too short, and I'd rather not strip it back any further since I don't have a lot of cord to work with. Since there are three wires (red, white, gold - ground) can I use either the red or the white as output, and the remaining color for ground, or do I have to use the gold cable for the ground and let the remaining wire dangle (taped)?Thanks

- They're just wires - you can do what you want with them. You run the risk of forgetting that you've ignored the colour coding though!

- Q: Hi,I have an issue with wiring in house. This is in Paris, France. I will share a foto so you can have a clearer picture what my question is.

- I'm not sure of your electrical system over there (except that it's 50HZ) The green/yellow wire is probably the ground (see which one is screwed into the frame of the oven to be sure) the other two shouldn't matter because it's probably a 240V unit, right?

- Q: is it safe to use twist on wire connector to connect my new stereo or should i crimp instead?

- Professional installers never use twist-on wire nuts for car audio wiring. They're fine for connecting solid wires in home wiring, but they're not made for connecting multi-strand wires in an environment with as much vibration as a vehicle. Eventually they'll fall off and you'll have a short circuit. You can use crimp-on barrel connectors, crimp bell caps, or solder your connections and cover them with shrink tubing or high-quality electrical tape. (Never use cheap electrical tape to insulate a connection--it will turn brittle and fall off over time). I like to use crimp caps.

- Q: i changed the sprak plugs wires on my 1990 300e and when i put the car on Drive it vibrates strongly. i kept checking that each wire is in the right place and on. do i need to restart the brain or reprogram the car ?

- Sounds like if you are sure the wires are in the right place, you might have spiked the coil assy. I would buy a $7.00 spark tested and make sure all wires are sending spark to the plugs.

- Q: When I am wiring my sub to my amp, what gauge of wire should I use? The sub is 750 rms and the amp is 700 rms. And how do I wire a 2 ohm sub DVC to a 2 ohm stable amp?

- The okorder /

- Q: I like bending paperclips to make things, does anyone know where you could buy spools of the wire paperclips are made out of.(any type of wire that is the same size and material will work)

- Paper Clip Wire

- Q: But I want to switch it and wire the red ceiling wire to the black fan wire and the black ceiling wire to the black/white fan wire so that the particular switches work the way I want them to. Is this ok, to switch them?

- Black wire on the fan is for the fan motor, red wire in the fan is for the light, the white wire is the neutral wire. So if you do want to switch the light off and on you have to tie red wire to the switch and the black wire can be tied to the hot at the ceiling box so you can control the fan with the chain only. If you have one switch leg in your circuit then you cannot do anything but switch them both if you tie them together. I think I am understanding what you are saying here. White Alyse ties to white Black is for the fan motor and the red is for the light. If you have three wires in the switch then you can tie them the same way color to color. Hope this has not confused you You can email me if you need further help

- Q: I think I have heard about flat cable wires?maybe even flat electrical wires.where you can hide them behind a base board.is this true?what are they called/thx

- flat co-ax cable would be an oxymoron, however there is flat twinlead. U need to know that twinlead is more likely to have interference problems though. electrical cable usually has 3 conductors so it is naturally kind of oval shaped people typically hide these behind baseboard or in the space below the baseboard if they have wall to wall

- Q: I attempted to change a bathroom fan to a new one with the help of a friend. He disconnected all the wiring without paying attention to what he was doing and what was wired where. We have a set of wires coming from somewhere (I presume the fuse box) to the fan that is hot regardless of the switch being on or off. That has a black, white and naked wire in it. Then we have another wire that comes from the switch that has black, white and naked as well. The fan has black, white and green. Can someone please tell me how to connect these as we have tried everything and the only thing that works is wired to the constant hot which of course won't allow us to turn the fan off with the switch...

- You need to pull your wall switch to see how it is wired. I suspect the original wiring used the black and white on the switch itself which would make the white actually black or hot instead of neutral. If on one side of the wall switch the black wire is wired and the other the white then you need to wire the black from the fuse panel to the black going to the switch. Then the white coming from the switch to the black on the fan. The white on the fuse panel wire would be wired to the white from the fan and all grounds(bare and green) wire together.

- Q: remote 2 wires for power black - white also 3 wires to goto fan/light ? white - black - red

- wire it black to black white to white. original wiring could be wrong. please better description. for light kit red or blue should connect to that. dont forget grounding wire even though white wire polarizes

Send your message to us

GALVANIZED AIRCRAFT CABLE 6X7. RR-W-410D

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords