GALVALUME Galvanized Steel Corrugated Roof Panel / Wall Panel / plate /Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GALVALUME Galvanized Steel Corrugated Roof Panel / Wall Panel / plate /Sheet

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Grade: | SGCC ,Q235 ,SPCC ,DC01, DX51D+Z | Thickness: | 0.15-1.2mm |

| Type: | Steel Plate | Technique: | cold rolled or hot rolled | Surface Treatment: | Galvanized,Chromated, dry or oiled |

| Application: | roofing sheet | Special Use: | High-strength Steel Plate | Width: | 790-1025mm |

| Length: | 1000-6000mm | price term: | FOB CFR CIF |

Specifications

price:advantage

delivery:fast

packing:as your requirment

Thickness | 0.13-0.8mm |

Width | 650-1100mm |

Length | 1700-5800mm |

Zinc / AZ coating | 50-275g/m2 |

Pitch | 76mm |

Wave height | 18mm or as request |

Wave No. | 8-12 |

Type | steel plate |

Weight of each package | about 3 mt |

Technology | cold rolled |

Material | SGCC SGCH SPCC DX51D+Z SGLCC DX51D+AZ |

Standard | ASTM,GB,JIS,DIN |

Price | FOB USD700-900 per mt |

Packing | packed in iron sheet lined with kraft paper or as per client's request. |

Surface treatment | galvanized,corrugated,bright finished,chromated,oiled(or unoiled)

|

Delivery time | within 20 days after receiving the down payment or irrevocable L/C at sight

|

Payment | 30% down payment of the total value by T/T and the balance must be paid by T/T or irrevocable L/C at sight after the goods finished. |

Application

a.) Attractive and innovative appearance, rich colors, decorative, flexible combination, can express a different architectural style;

b.) Light weight, high mechanical properties;

c.) Anti-earthquake, fire, rain, long life, no maintenance;

d.) Installation is simple, shorten the construction period;

e.) Environmental protection, etc.

a.) Industrial and civil buildings, warehouse;

b.) Special construction;

c.) Steel structure houses and mobile homes, roof, walls, and interior and exterior decoration, etc.

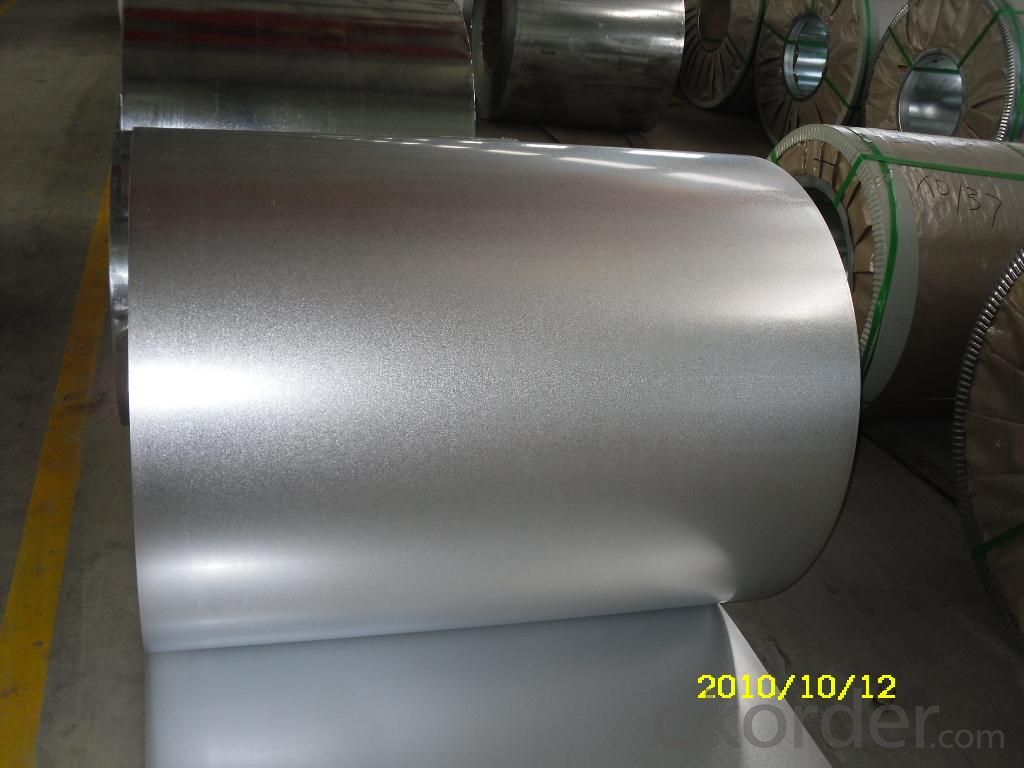

Picture:

- Q: How can the white steel plate be bright and cleaned?

- The corrosion resistance of white steel depends mainly on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and the internal structure of the alloy. The main element is chromium. Chromium has high chemical stability, can form a passive film on the steel surface, so that the metal is isolated from the outside, protect the steel plate from oxidation and increase the corrosion resistance of the steel plate. When the passive film is destroyed, the corrosion resistance will decrease.

- Q: Can steel sheets be used for manufacturing machinery parts?

- Yes, steel sheets can be used for manufacturing machinery parts. Steel is a strong and durable material that is commonly used in the manufacturing industry for various applications, including machinery parts. Steel sheets can be easily formed, cut, and welded to create complex shapes and structures required for machinery components. Additionally, steel offers excellent mechanical properties such as high tensile strength and resistance to wear, which are crucial for machinery parts that are subjected to heavy loads and frequent use.

- Q: What is the average lifespan of a steel sheet roof?

- The average lifespan of a steel sheet roof can vary depending on various factors such as the quality of materials used, installation techniques, climate conditions, and maintenance. However, on average, a well-maintained steel sheet roof can last anywhere from 20 to 50 years.

- Q: Can the steel sheets be easily formed into curves or angles?

- Yes, steel sheets can be easily formed into curves or angles using various techniques such as bending, rolling, or shaping.

- Q: Can steel sheets be used for mezzanine floors?

- Yes, steel sheets can be used for mezzanine floors. Steel sheets are commonly used in construction for their strength and durability, making them suitable for supporting the load requirements of mezzanine floors. They can provide a solid and stable surface for various applications, such as storage or additional workspace.

- Q: How do steel sheets handle chemical exposure?

- Steel sheets are renowned for their outstanding ability to resist chemical exposure. They exhibit a high level of resistance to corrosion and can endure exposure to a wide array of chemicals, including acids, alkalis, solvents, and other substances that cause corrosion. This exceptional resistance is primarily attributed to the formation of a protective oxide layer, known as patina, on the surface of the steel. This layer acts as a barrier, preventing the chemicals from attacking the steel. Moreover, steel sheets can be further safeguarded by applying various protective coatings, such as galvanization, epoxy coatings, or powder coatings. These coatings provide an extra layer of protection and enhance the steel's resistance to chemical exposure. However, it is important to acknowledge that the resistance of steel sheets to chemical exposure may vary based on the specific type and concentration of the chemicals involved. Highly concentrated or aggressive chemicals may still lead to some degree of corrosion or damage to the steel surface over time. Hence, it is crucial to carefully consider the specific chemical environment and select the appropriate grade of steel and protective coating to ensure optimum resistance to chemical exposure. In summary, steel sheets are a dependable and durable choice for applications that demand resistance to chemical exposure. With careful selection and maintenance, they can effectively withstand diverse chemical environments and deliver long-lasting performance.

- Q: Can steel sheets be used for agricultural equipment?

- Yes, steel sheets can be used for agricultural equipment. Steel is a versatile and durable material that is commonly used in the fabrication of various agricultural machinery and equipment. It is known for its strength, rigidity, and resistance to wear and tear, making it suitable for heavy-duty applications in farming and agriculture. Steel sheets can be used to manufacture a wide range of agricultural equipment, such as plows, cultivators, seeders, harvesters, trailers, and storage containers. These equipment require sturdy materials to withstand the demanding conditions of the agricultural environment, including exposure to soil, moisture, and heavy loads. Steel sheets can be formed and manipulated into different shapes and sizes, allowing for the customization of agricultural equipment to meet specific requirements. Additionally, steel can be easily welded, ensuring the structural integrity of the equipment and enabling repairs if necessary. Furthermore, steel sheets can be coated or galvanized to enhance their corrosion resistance, further increasing their longevity and durability in agricultural applications. This helps to protect the equipment from rust and deterioration caused by exposure to various weather conditions and chemicals commonly found in farming activities. Overall, steel sheets are a suitable material for agricultural equipment due to their strength, durability, and versatility. Their use in the manufacturing of agricultural machinery helps to ensure reliable and efficient performance, contributing to the productivity and success of farming operations.

- Q: Is color steel plate the same as color steel tile?

- Some people call this product "pre roll painted steel plate" and "plastic color steel plate".Color steel products are manufacturers in continuous production line volume production, it is also called color coated steel coil. Color steel plate not only has high mechanical strength, easy molding property, but also has good decorative and corrosion resistance. Color steel plate is a new material respected by the world. With the progress of science and technology, enhance the awareness of the environment, improve people's living standards, color plate activity room shows more and more strong vitality and broad market prospects, by construction, household appliances, electronics, transportation, interior decoration, office equipment and other industries favored.

- Q: Are steel sheets resistant to discoloration from sunlight?

- Yes, steel sheets are generally resistant to discoloration from sunlight.

- Q: Are steel sheets suitable for manufacturing kitchen appliances?

- Yes, steel sheets are suitable for manufacturing kitchen appliances. Steel is a versatile and durable material that is commonly used in the manufacturing industry. It has high strength, which makes it suitable for withstanding the daily wear and tear of kitchen appliances. Steel sheets are also resistant to corrosion, which is important in a kitchen environment where appliances are constantly exposed to water, moisture, and food spills. Additionally, steel is a hygienic material that is easy to clean and maintain, making it ideal for kitchen appliances where cleanliness is crucial. Furthermore, steel sheets can be easily shaped and formed into different designs and sizes, allowing for a wide variety of kitchen appliances to be manufactured. Overall, steel sheets provide the necessary properties and characteristics required for the manufacturing of kitchen appliances.

Send your message to us

GALVALUME Galvanized Steel Corrugated Roof Panel / Wall Panel / plate /Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords