High-Quality FRP Roofing Panel - Corrugated Fiberglass Sheets on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

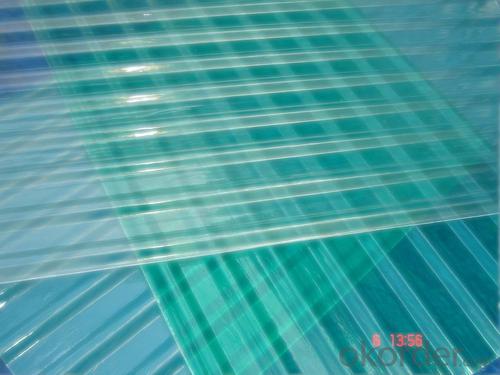

PICTURES

- Q: Are FRP roofing panels resistant to impact from falling debris?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to impact from falling debris. The fiberglass composition provides strength and durability, making them able to withstand the impact without significant damage. However, the level of resistance may vary depending on the specific type and thickness of the FRP panels.

- Q: Can FRP roofing panels be used for retail stores?

- Yes, FRP roofing panels can be used for retail stores. FRP (Fiberglass Reinforced Plastic) roofing panels are durable, lightweight, and provide excellent protection against weather elements. They are cost-effective, low-maintenance, and can be easily installed. Additionally, FRP panels are available in various colors and designs, allowing them to enhance the aesthetics of retail stores. Overall, FRP roofing panels are a suitable choice for retail store applications.

- Q: Can FRP roofing panels be used for skylights in sports facilities?

- Skylights in sports facilities can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess qualities that make them an excellent choice, including being lightweight, durable, and having exceptional light transmission capabilities. These attributes make FRP panels perfectly suited for skylights. Moreover, they offer resistance to UV radiation, impact, and weathering, which are vital features for outdoor sports facilities. Furthermore, FRP panels can be tailored to meet specific design requirements, allowing for various shapes, sizes, and colors. This adaptability enables seamless integration of skylights into the architectural design of sports facilities, while simultaneously providing natural light to the interior spaces. In summary, FRP roofing panels provide a cost-effective and dependable solution for creating skylights in sports facilities.

- Q: Are FRP roofing panels soundproof?

- FRP (Fiberglass Reinforced Panels) roofing panels are not specifically designed to be soundproof. While they may provide some level of sound insulation due to their construction and material properties, they are not as effective as dedicated soundproofing materials or systems. The primary function of FRP roofing panels is to provide durability, weather resistance, and natural light transmission, rather than noise reduction. If soundproofing is a priority, it is recommended to explore alternative solutions specifically designed for sound insulation, such as acoustic panels or soundproofing materials applied beneath or on top of the roofing panels.

- Q: Can FRP roofing panels be used for both new construction and roof replacements?

- FRP roofing panels are suitable for new construction as well as roof replacements. They can be easily installed on different types of structures, such as residential, commercial, and industrial buildings. These panels are lightweight, durable, and have exceptional weather resistance, making them ideal for new roofs or replacing old or damaged ones. Moreover, their low maintenance requirements and simplicity of installation make FRP panels a cost-effective choice for any construction or replacement endeavor.

- Q: Are FRP roofing panels resistant to warping or bowing?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to warping or bowing. The unique composition of FRP panels, which consists of a reinforced fiberglass layer embedded in a plastic resin matrix, provides excellent structural integrity and dimensional stability. This construction makes FRP panels highly resistant to the effects of temperature changes, moisture, and UV exposure, which are common causes of warping or bowing in other roofing materials. Furthermore, FRP panels are designed to withstand heavy loads and resist flexing. Their high strength-to-weight ratio ensures that they maintain their shape and structural integrity over time, even under significant external pressures. As a result, FRP roofing panels are ideal for applications where flatness and stability are essential, such as in industrial buildings, agricultural structures, or commercial facilities. However, it is important to note that extreme conditions or poor installation practices can potentially lead to some degree of warping or bowing in FRP roofing panels. Therefore, it is crucial to follow manufacturer guidelines and specifications during installation to ensure optimal performance and minimize any potential issues.

- Q: Can FRP roofing panels be installed in low-pitched roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed in low-pitched roofs. FRP panels have excellent waterproofing properties and can be effectively used in roofs with a low slope. However, it is important to ensure proper installation and use appropriate sealants to prevent any potential leaks.

- Q: Do FRP roofing panels require any specific cleaning products?

- FRP (Fiberglass Reinforced Plastic) roofing panels typically do not require any specific cleaning products. In fact, using harsh chemicals or abrasive materials can potentially damage the panels. Instead, a regular cleaning routine with mild soap or detergent and water is usually sufficient to keep FRP roofing panels clean and in good condition. It is important to avoid using solvents, strong acids, or alkalis on the panels as these can cause discoloration or deterioration. Additionally, using a soft cloth or sponge for cleaning and gently rinsing the panels afterwards is recommended to prevent any scratches or marks.

- Q: Scrap glass fiber reinforced plastic water tank board what to use, where there is recycling?

- Mainly depends on the aging situation, such as showing no cracks, no deformation, these panels in combination into small water tanks or low pressure water tank

- Q: Do FRP roofing panels come in different colors?

- Yes, FRP roofing panels come in different colors.

Send your message to us

High-Quality FRP Roofing Panel - Corrugated Fiberglass Sheets on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords