FRP Roofing Panel - High Strength Fiberglass Corrugated Roofing Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fibreglass / Fiberglass Reinforced Plastic (FRP) or Glass Fiber Reinforced Plastic (GRP) is composed of thermosetting plastics and reinforced fiberglass, Greater than that of steel products and aluminum products in specific tenacity. Products in the ultra-low temperature or high temperature will not happen brittle fracture, deformation and to prevent heat transfer. Corrosion products in the environment anti-aging, yellowing resistance, corrosion resistance, friction resistance, easy to clean. Can be instead of aluminum, stainless steel plates, tiles and so on.

FEATURES

1.corrosion resistance no rust, no maintenance, long service life.

2.lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%), the one way than intensity and stiffness is quite prominent, the density of glass fiber reinforced plastic is only about a quarter of the steel, light weight, very easy to handle, so as to reduce the handling fee.

3..Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

4.anti-aging select highquality FRP pultrusion profiles, the service life of the product can reach more than 20 years, and in all the pultrusion FRP profiles were added in the formula of an-uv agent in order to get the best anti-uv effect.

5.excellent electromagnetic performance it has excellent electrical insulation, electrical, magnetic and electric spark can be used in risk conduction,

sensitive to magnetic equipment area, and flammable and explosive place.

SPECIFICATION

| Product Details | |

| Brand | CMAX |

| Model NO. | BQ-1111 |

| Color | Any Pantone color or multi-colors can be customized. |

| Size | Length: any length you want |

| width: 660mm | |

| thickness: 3mm | |

| surface | glossy |

| MOQ: | 50 meter |

| Payment Term: | TT(Telegraphic Transfer),L/C(letter of credit), Paypal, western union, HSBC Hong Kong. |

| Production Capacity: | 70000pcs Per week |

| Shipping | DHL,FEDEX |

| Additional term | 1. Any customized shape and size are available. 2. If necessary,we will provide some professional suggestion for your reference. |

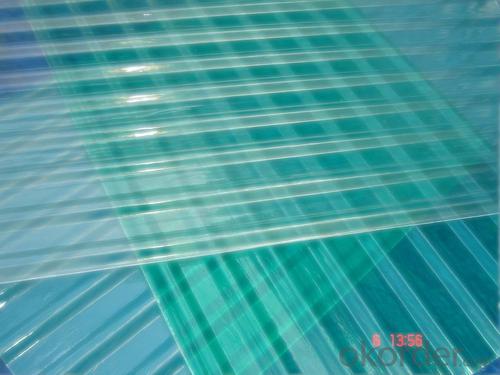

PICTURES

- Q: Can FRP roofing panels be curved or molded?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be curved or molded to fit different architectural designs and shapes. The flexibility of FRP allows for customization and versatility in roofing applications, enabling the creation of curved or molded panels to meet specific project requirements.

- Q: Can FRP roofing panels be used in modular construction?

- Modular construction can benefit from the utilization of FRP roofing panels. FRP, otherwise known as Fiber Reinforced Polymer, is a resilient and sturdy material frequently employed in construction due to its lightweight composition and resistance to corrosion and weathering. In the realm of modular construction, where buildings are constructed off-site in sections or modules and subsequently transported for assembly at the final location, the incorporation of FRP roofing panels can present several advantages. Firstly, the lightweight nature of FRP panels facilitates their handling and transportation, thereby contributing to the efficiency of modular construction. Moreover, FRP roofing panels offer exceptional insulation properties, thereby aiding in temperature regulation and reducing energy consumption within modular buildings. This is particularly advantageous in modular construction, where the maintenance of energy efficiency is crucial to sustainable and cost-effective building practices. Furthermore, FRP roofing panels exhibit high resistance to inclement weather, enduring extreme temperatures, UV rays, and moisture. This renders them a dependable choice for modular construction, particularly during transportation and assembly, when the durability of building materials is of utmost importance. Lastly, FRP roofing panels provide design flexibility, as they can be manufactured in a variety of colors, finishes, and profiles to align with the aesthetic requirements of the modular construction project. In summary, the lightweight composition, insulation properties, durability, and design flexibility of FRP roofing panels make them an ideal choice for modular construction. Their integration enhances the efficiency, sustainability, and aesthetics of modular buildings.

- Q: Can FRP roofing panels be used for walkway canopies?

- FRP roofing panels are indeed suitable for walkway canopies. These panels possess qualities like lightweightness, durability, and excellent weather resistance, which render them perfect for outdoor usage, specifically in walkway canopies. They also come in a variety of colors and designs, enabling customization based on aesthetics. Furthermore, these panels offer satisfactory light transmission and protect against harmful UV rays. In conclusion, FRP roofing panels offer an economical and enduring alternative for walkway canopies.

- Q: Can FRP roofing panels be installed on historical or heritage buildings?

- FRP roofing panels, also known as fiberglass reinforced plastic roofing panels, can indeed be installed on historical or heritage buildings. However, there are certain considerations that need to be taken into account before proceeding with the installation. First and foremost, it is crucial to assess the historical significance of the building and evaluate the impact that installing FRP roofing panels would have on its overall integrity and aesthetic value. Some historical or heritage buildings may be protected by strict conservation regulations, and any alteration to the original structure may require permission or approval from the relevant authorities. Additionally, the compatibility of FRP roofing panels with the existing roof structure needs to be carefully evaluated. Historical buildings often have unique architectural features, such as intricate designs, delicate materials, or unconventional roof shapes. It is important to ensure that the installation of FRP panels does not compromise the structural integrity or alter the appearance of these distinctive characteristics. Moreover, the choice of FRP roofing panels should be made with consideration for the specific requirements of historical buildings. Opting for panels that mimic the appearance of traditional roofing materials, such as clay tiles or slate, can help maintain the historical aesthetics while benefiting from the durability and longevity of FRP. Lastly, it is advisable to consult with professionals experienced in working with historical or heritage buildings and materials. These experts can provide valuable insights and guidance on the best practices for installing FRP roofing panels without compromising the historical value or architectural integrity of the structure. In conclusion, while it is possible to install FRP roofing panels on historical or heritage buildings, thorough research, evaluation, and consultation with experts are essential to ensure that the installation is carried out in a manner that respects and preserves the building's historical significance.

- Q: Are FRP roofing panels resistant to termites or other pests?

- Termites and other pests are not typically deterred by FRP (Fiberglass Reinforced Plastic) roofing panels. Although FRP materials are recognized for their resilience and ability to withstand various elements, they remain vulnerable to termite infestation and damage caused by other pests. Termites, specifically, are known to consume and tunnel through wood and cellulose-based materials, which FRP panels lack. Nonetheless, termites can still harm the wooden structures adjacent to the FRP panels, potentially jeopardizing the roofing system's integrity. It is advisable to regularly examine and maintain the area surrounding FRP roofing panels to prevent potential pest infestations and promptly address any concerns.

- Q: Are FRP roofing panels easy to repair?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally easy to repair. They are lightweight and can be easily patched or replaced in case of damage. Additionally, the panels can be cut and shaped to fit specific areas, making repairs more convenient.

- Q: Are FRP roofing panels fire-resistant?

- Indeed, FRP (Fiberglass Reinforced Plastic) roofing panels possess fire-resistant qualities. Their composition comprises a blend of fortified fiberglass and plastic resin, endowing them with superb resistance against fire. These panels boast a substantial ignition temperature and do not emit any noxious or detrimental fumes when subjected to flames. Furthermore, FRP roofing panels have the ability to self-extinguish, ceasing to burn once the fire's origin is eliminated. Consequently, they serve as a secure option for roofing purposes, especially in regions prioritizing fire safety.

- Q: Are FRP roofing panels resistant to acid rain or pollutants?

- FRP roofing panels possess a remarkable resistance to acid rain and pollutants, making them an ideal solution for areas prone to these environmental factors. Comprised of a blend of fiberglass and plastic resin, FRP panels exhibit exceptional resistance to corrosive chemicals, including the acids found in acid rain. This durability ensures that FRP roofing panels maintain their longevity even in the harshest conditions. The fiberglass component of FRP panels provides the necessary strength and stability, while the plastic resin acts as a protective shield against external elements. As a result, FRP panels effectively resist the detrimental effects of acid rain and pollutants, such as rust, corrosion, and discoloration. In addition, FRP panels are often equipped with a UV-resistant coating that further enhances their ability to withstand environmental factors such as acid rain and pollutants. This protective coating prevents degradation caused by prolonged exposure to sunlight and chemical reactions. It is important to recognize that the level of resistance to acid rain and pollutants may vary depending on the specific composition and quality of the FRP panel. Consequently, it is advisable to select high-quality FRP roofing panels from reputable manufacturers that offer guarantees or certifications specifically related to resistance against acid rain and pollutants. Overall, FRP roofing panels are a reliable choice for safeguarding against the damaging effects of acid rain and pollutants. They ensure long-lasting durability and performance for various construction projects.

- Q: Can FRP roofing panels be used for covered parking structures or garages?

- FRP roofing panels are suitable for covered parking structures or garages due to their lightweight, durability, and excellent weather resistance. They effectively protect vehicles from the elements. Moreover, FRP panels are corrosion-resistant, can withstand UV rays and chemicals, making them a reliable choice for outdoor use. Installing the panels is effortless and cost-effective for creating covered parking areas or garages. However, it is crucial to ensure that the structural support system is capable of handling the weight and load of the panels, as well as any potential snow or wind loads in the area. Proper installation and regular maintenance are also necessary to ensure the longevity and performance of the FRP roofing panels in these applications.

- Q: Are FRP roofing panels resistant to damage from extreme temperatures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to damage from extreme temperatures. The combination of fiberglass and plastic materials used in FRP panels allows them to withstand a wide range of temperatures without warping, cracking, or deforming. However, it's important to note that the specific resistance may vary depending on the quality and thickness of the panel, as well as the severity and duration of the extreme temperatures.

Send your message to us

FRP Roofing Panel - High Strength Fiberglass Corrugated Roofing Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords