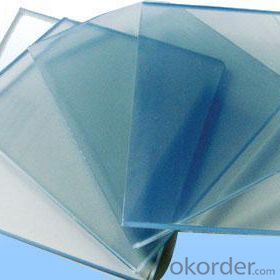

FRP Roofing Panel - Fibreglass Reinforced Polyester (FRP) Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fibreglass / Fiberglass Reinforced Plastic (FRP) or Glass Fiber Reinforced Plastic (GRP) is composed of thermosetting plastics and reinforced fiberglass, Greater than that of steel products and aluminum products in specific tenacity. Products in the ultra-low temperature or high temperature will not happen brittle fracture, deformation and to prevent heat transfer. Corrosion products in the environment anti-aging, yellowing resistance, corrosion resistance, friction resistance, easy to clean. Can be instead of aluminum, stainless steel plates, tiles and so on.

FEATURES

Corrosion resistance,last 10-15 years life span

Color stable.

Sound absorption and heat insulation.

Good water resistance.

Fireproof resistance.

Easy to install.

Good impact and low temperature resistance.

Light weight.

Stable volume.

SPECIFICATIONS

| Name: | Fibreglass Reinforced Polyester(FRP ) Sheet |

| Material: | Protective film, Unsaturated resin polyester, Fiberglass |

| Weight: | 1800g/2400g/2750g/3050g Square meter |

| Thickness: | 0.8~3.0mm |

| Length: | Customized |

| Temp: | used in -40°c to 140 °c |

| OEM: | Welcomed |

| Color: | Clear/Blue |

PICTURES

- Q: Can FRP roofing panels be used in high wind areas?

- FRP (Fiberglass Reinforced Plastic) roofing panels are capable of being utilized in areas with high wind. These panels possess a reputation for their exceptional strength and durability, rendering them suitable for enduring powerful winds. Nevertheless, it is imperative to ensure that the panels are installed and anchored correctly to the structure in order to prevent any potential damage or displacement during high wind conditions. Furthermore, it is advisable to opt for panels specifically designed to withstand high wind loads, as they come with additional reinforcement and structural features that enhance their performance in such areas. In summary, when installed properly and selected appropriately, FRP roofing panels can serve as a dependable choice for areas prone to high winds.

- Q: Are FRP roofing panels resistant to algae growth?

- Yes, FRP roofing panels are generally resistant to algae growth due to their smooth and non-porous surface, making them an ideal choice for areas prone to algae growth and requiring low maintenance.

- Q: Can FRP roofing panels be used for canopies?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for canopies. FRP panels are known for their durability, lightweight nature, and resistance to corrosion and UV rays. These qualities make them ideal for outdoor applications such as canopies. Additionally, FRP panels are available in various thicknesses, colors, and translucencies, allowing for customization to suit the specific design and aesthetic requirements of the canopy. Whether for residential or commercial purposes, FRP roofing panels can provide a sturdy and long-lasting solution for canopy construction.

- Q: How do FRP roofing panels compare to metal roofing in terms of durability?

- FRP roofing panels, also known as fiberglass reinforced plastic panels, are highly durable and offer several advantages over metal roofing in terms of durability. While metal roofing is also known for its longevity, FRP panels have a longer lifespan due to their resistance to corrosion, rust, and weathering. Unlike metal, FRP panels are made of a composite material that combines fiberglass and plastic, creating a lightweight yet sturdy roofing option. This composition makes FRP panels more resistant to damage from extreme weather conditions such as hail, heavy rain, and strong winds. In contrast, metal roofing may dent or become damaged under similar circumstances. Furthermore, FRP panels have excellent UV resistance, meaning they are less likely to fade or degrade when exposed to sunlight. Metal roofing, on the other hand, may experience color fading or surface deterioration over time due to prolonged exposure to the sun's rays. This makes FRP panels a more suitable choice for areas with high sun exposure. Another factor that adds to the durability of FRP roofing panels is their resistance to chemicals and corrosive substances. They can withstand exposure to various chemicals, including acids and alkalis, without deteriorating or losing their structural integrity. In contrast, metal roofing may be susceptible to corrosion when exposed to certain chemicals or corrosive environments. Additionally, FRP panels offer excellent insulation properties, helping to regulate the temperature inside the building. This can contribute to energy efficiency and reduce heating and cooling costs. Metal roofing, on the other hand, may transfer heat more readily, potentially increasing energy consumption for temperature control. In summary, while both FRP roofing panels and metal roofing are durable options, FRP panels have several advantages in terms of longevity. They are highly resistant to corrosion, rust, weathering, and UV radiation. Their composite composition and resistance to chemicals make them a reliable choice for long-term durability.

- Q: Can FRP roofing panels be used for walkways or pedestrian bridges?

- Indeed, FRP roofing panels possess the capability to be utilized for walkways or pedestrian bridges. Renowned for their exceptional strength-to-weight ratio, durability, and resistance to corrosion, FRP panels prove to be a fitting choice for such purposes. Despite their lightweight nature, these panels exhibit ample strength to withstand pedestrian traffic. Furthermore, FRP panels can be designed to incorporate non-slip surfaces, ensuring optimal safety for pedestrians. Moreover, the installation of these panels is effortless and their maintenance requirements are minimal, rendering them a cost-effective selection for walkways or pedestrian bridges. In summary, FRP roofing panels serve as a dependable option for the creation of secure and long-lasting pathways for pedestrians.

- Q: Are FRP roofing panels UV resistant?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are UV resistant. FRP roofing panels are specifically designed to withstand the damaging effects of UV (ultraviolet) radiation from the sun. They are manufactured with a protective gel coating that acts as a barrier against UV rays, preventing them from causing discoloration, fading, or degradation of the material over time. This UV resistance helps to maintain the aesthetic appearance and structural integrity of FRP roofing panels, making them a durable and long-lasting roofing solution for various applications.

- Q: Are FRP roofing panels compatible with rooftop gardens or hydroponic systems?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are compatible with rooftop gardens or hydroponic systems. These panels are lightweight, durable, and resistant to corrosion and UV rays, making them suitable for supporting the weight of plants and handling water and nutrient solutions. Additionally, FRP panels can be easily customized to accommodate irrigation systems and drainage requirements, making them an ideal choice for rooftop gardening or hydroponic setups.

- Q: Can FRP roofing panels be used in hospitals or healthcare facilities?

- Yes, FRP roofing panels can be used in hospitals or healthcare facilities. FRP (Fiberglass Reinforced Plastic) roofing panels are durable, lightweight, and resistant to corrosion, making them suitable for such environments. They are also easy to clean and maintain, helping to maintain a hygienic and sterile environment in healthcare facilities. Additionally, FRP panels offer good thermal insulation properties and can be designed to meet specific fire safety and acoustic requirements, making them a practical choice for hospitals and healthcare facilities.

- Q: Are FRP roofing panels suitable for hospitals or healthcare facilities?

- Yes, FRP roofing panels are suitable for hospitals and healthcare facilities. They are durable, lightweight, and resistant to corrosion and chemicals, making them ideal for environments that require high levels of hygiene and cleanliness. Additionally, FRP panels are easy to clean and maintain, reducing the risk of bacterial growth and ensuring a safe and healthy environment for patients and staff.

- Q: Can FRP roofing panels be used in churches or religious buildings?

- FRP roofing panels are a suitable choice for churches or religious buildings due to their durability, lightweight nature, and exceptional weather resistance. These panels are commonly used in commercial and industrial structures but can also be utilized in religious establishments. One notable advantage of FRP panels is their ability to allow natural light into the building while providing insulation. This creates a warm and inviting atmosphere, especially in churches where natural light is desired. Additionally, these panels are available in a variety of colors and finishes, allowing customization to match the aesthetic of the religious building. Moreover, FRP panels are easy to install and maintain, making them a cost-effective option for churches or religious buildings with limited budgets. They possess resistance against corrosion, rust, and UV radiation, ensuring their durability and reducing the need for frequent repairs or replacements. However, it is crucial to consult with a professional or roofing specialist to assess the specific requirements and determine if FRP panels are the optimal choice for a particular church or religious building. Factors such as local climate, building codes, architectural design, and structural considerations must be carefully considered before reaching a final decision.

Send your message to us

FRP Roofing Panel - Fibreglass Reinforced Polyester (FRP) Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords