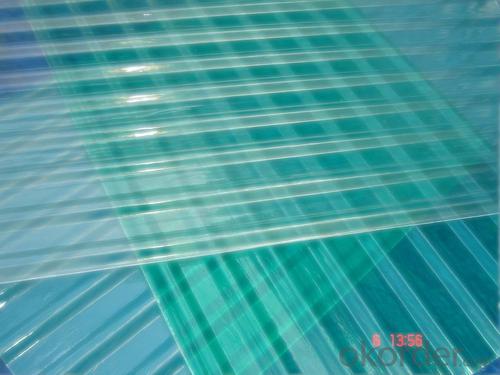

China FRP Roof Panels - High Quality Fiberglass Reinforced Plastic FRP Flat Roofing Sheet On Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATIONS

Thickness | Mesh size | Panel size | Open area | Weight |

(MM) | (MM) | (MM) | % | (kg/m2) |

25 | 38*38 | 1220*3660 | 68 | 12.5 |

1220*4076 | ||||

1220*4000 | ||||

30 | 38*38 | 1220*3660 | 68 | 14.75 |

1220*4000 | ||||

38 | 38*38 | 1007*4047 | 68 | 19.5 |

1220*3660 | ||||

1220*4000 | ||||

50.7 | 50.7*50.7 | 1220*3660 | 71 | 23.5 |

1220*4000 | ||||

30 | 19*19 | 1007*4007 | 40 | 18.1 |

38 | 19*19 | 1007*4007 | 40 | 23.5 |

PICTURES

- Q: Can FRP roofing panels be used for retail stores?

- Indeed, retail stores can make use of FRP (Fiberglass Reinforced Plastic) roofing panels. It is not uncommon to find FRP roofing panels in commercial and industrial buildings owing to their durability, versatility, and cost-effectiveness. Being lightweight and simple to install, they are also capable of enduring harsh weather conditions, which renders them appropriate for retail establishments. Moreover, these panels are accessible in a variety of colors and designs, enabling retailers to select a style that harmonizes with their brand identity. Furthermore, FRP roofing panels exhibit resistance to UV rays, chemicals, and corrosion, ensuring that retail establishments have a long-lasting solution at their disposal.

- Q: Can FRP roofing panels be installed on greenhouses or botanical gardens?

- FRP roofing panels are capable of being installed in both greenhouses and botanical gardens. These panels possess numerous advantageous characteristics, including their lightweight composition, durability, and exceptional thermal insulation capabilities. Consequently, they prove to be an optimal choice for such structures. Furthermore, FRP panels exhibit resistance to UV radiation, chemicals, and moisture, all of which are commonly encountered within greenhouse and botanical garden settings. This resistance enables the panels to effectively shield plants from the elements while simultaneously facilitating the transmission of ample natural light. By incorporating FRP roofing panels, one can achieve a cost-effective, long-lasting, and visually appealing solution for maintaining a controlled environment conducive to plant growth in greenhouses or botanical gardens.

- Q: Are FRP roofing panels prone to discoloration from air pollution?

- Yes, FRP roofing panels are generally prone to discoloration from air pollution. The pollutants in the air, such as smog, industrial emissions, and dust particles, can gradually cause discoloration on the surface of FRP panels over time. However, the extent of discoloration may vary depending on the specific composition and quality of the FRP panels, as well as the severity of air pollution in the area. Regular cleaning and maintenance can help minimize discoloration and preserve the appearance of FRP roofing panels.

- Q: Are FRP roofing panels resistant to cracking or splitting?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to cracking or splitting. FRP panels are made by combining fiberglass and plastic resin, resulting in a durable and strong material that can withstand a wide range of weather conditions and mechanical stress. The fiberglass reinforcement provides added strength and rigidity to the panels, making them highly resistant to cracking or splitting, even under heavy loads or impact. Additionally, FRP roofing panels are designed to be flexible, which further reduces the risk of cracking or splitting. Overall, FRP roofing panels are a reliable and long-lasting solution that can withstand various external forces without compromising their structural integrity.

- Q: Can FRP roofing panels be installed on both residential and commercial buildings?

- Yes, FRP roofing panels can be installed on both residential and commercial buildings. FRP panels are versatile and can be used in various applications, including homes, offices, warehouses, and industrial buildings. They offer durability, lightweight construction, and resistance to weathering, making them suitable for both residential and commercial roofing needs.

- Q: Are FRP roofing panels resistant to oil or grease stains?

- Generally, oil and grease stains do not adhere easily to FRP (Fiberglass Reinforced Plastic) roofing panels due to their smooth surface. This makes cleaning and maintenance of FRP panels easy. However, it is crucial to consider that the resistance level may differ depending on the type and quality of the FRP panel. For detailed information regarding the resistance of the specific FRP roofing panel being utilized, it is advisable to consult the manufacturer or supplier.

- Q: Are FRP roofing panels prone to discoloration?

- Yes, FRP roofing panels are prone to discoloration over time due to exposure to UV rays and other environmental factors. This can result in a faded or yellowish appearance, affecting the aesthetic appeal of the panels. However, regular maintenance and the application of protective coatings can help prevent or minimize discoloration.

- Q: Can FRP roofing panels be used in cold climates?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in cold climates. FRP roofing panels are known for their durability and ability to withstand extreme weather conditions, including cold temperatures. They have excellent thermal insulation properties, which help to prevent heat loss and keep the interior of buildings warm. Additionally, FRP panels are resistant to damage caused by freezing and thawing cycles, making them a suitable choice for cold climates where temperature fluctuations are common. However, it is important to ensure proper installation and maintenance of FRP roofing panels to maximize their performance and longevity in cold weather conditions.

- Q: Can FRP roofing panels be used in commercial buildings?

- FRP roofing panels have the ability to be utilized in commercial buildings. Their durability, strength, and resistance to different environmental elements make them a favored choice for these types of structures. Despite being lightweight, they offer superb protection against UV rays, extreme temperatures, and corrosion. Moreover, FRP panels are simple to install, require minimal upkeep, and can be tailored to fit specific design needs. Their cost-effectiveness also makes them a sensible choice for owners of commercial buildings. In conclusion, FRP roofing panels are a viable option for commercial buildings, offering enduring and dependable roofing solutions.

- Q: Are FRP roofing panels suitable for canopies or awnings?

- Yes, FRP roofing panels are suitable for canopies or awnings. FRP (Fiberglass Reinforced Plastic) panels are lightweight, durable, and resistant to weathering, making them an ideal choice for outdoor structures such as canopies or awnings. They provide excellent strength and protection against UV rays, rain, and other external elements, ensuring long-lasting performance and aesthetic appeal.

Send your message to us

China FRP Roof Panels - High Quality Fiberglass Reinforced Plastic FRP Flat Roofing Sheet On Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords