Sewing Fiberglass Fabric FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pultrusion Roof Tile Sheets or Panels

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. Corrosion resistance no rust, no maintenance, long service life.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. The intensity and stiffness is quite prominent,.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

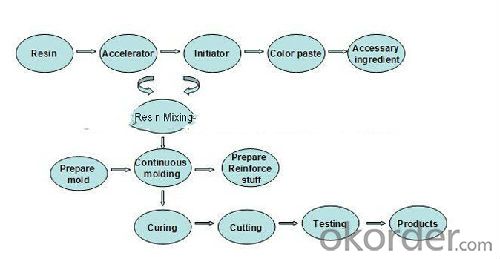

Production Process

Specification

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: What are the disadvantages of using fiberglass fabric?

- One disadvantage of using fiberglass fabric is that it can be brittle and prone to cracking or breaking under certain conditions. Additionally, fiberglass fabric can be quite irritating to the skin and respiratory system, requiring the use of protective gear when working with it. Furthermore, fiberglass fabric is not as flexible as other materials, making it more challenging to work with in certain applications. Finally, fiberglass fabric can be more expensive compared to alternative fabric options, making it less cost-effective for certain projects.

- Q: Can fiberglass fabric be used for reinforcement in sporting equipment?

- Certainly, sporting equipment can benefit from the utilization of fiberglass fabric for reinforcement purposes. Renowned for its remarkable durability and impressive strength-to-weight ratio, fiberglass fabric proves to be highly suitable for a wide range of applications, including the field of sporting equipment. By incorporating fiberglass fabric, items like skis, surfboards, tennis rackets, bicycles, and hockey sticks, among others, can have their structural integrity fortified. Typically, the fiberglass fabric is skillfully layered or laminated alongside other materials, resulting in a composite structure that simultaneously provides enhanced strength and stiffness while remaining lightweight. This reinforcement significantly elevates the performance and lifespan of the sporting equipment, rendering it an exceedingly favored choice among manufacturers.

- Q: Can fiberglass fabric be used for making protective sleeves and gloves?

- Protective sleeves and gloves can be made using fiberglass fabric, which is renowned for its outstanding resistance to heat, durability, and insulation properties. These attributes render it appropriate for tasks necessitating protection against elevated temperatures, sparks, and molten metal. The utilization of fiberglass fabric in the production of protective sleeves and gloves ensures a dependable shield against heat and flames. It can endure temperatures of up to 1000 degrees Fahrenheit, making it particularly well-suited for sectors like welding, foundries, and glass manufacturing. Moreover, fiberglass fabric boasts wear-resistance, tear-resistance, and excellent tensile strength, guaranteeing that the resulting protective sleeves and gloves are long-lasting and offer reliable protection. Furthermore, the fabric is lightweight and flexible, facilitating ease of movement and dexterity, which is crucial for tasks requiring fine motor skills. Nevertheless, it is worth noting that fiberglass fabric has the potential to cause skin irritation. Consequently, it is frequently coated or lined with other materials to prevent direct contact with the skin. This lining or coating not only enhances comfort but also provides supplementary protection against potential skin allergies or irritation. In conclusion, fiberglass fabric proves to be a suitable material for the production of protective sleeves and gloves due to its heat resistance, durability, and insulation properties. It offers dependable defense against high temperatures, sparks, and molten metal, making it an exceptional choice for individuals employed in industries exposed to heat and flame hazards.

- Q: Can fiberglass fabric be used for reinforcement in power plant tanks?

- Yes, fiberglass fabric can be used for reinforcement in power plant tanks. Fiberglass fabric is a strong and durable material that is commonly used for reinforcement applications in various industries, including power plants. It offers high tensile strength and excellent resistance to corrosion, chemicals, and extreme temperatures. Additionally, fiberglass fabric is lightweight and easy to handle, which makes it a practical choice for reinforcing tanks in power plants. It can help enhance the structural integrity of the tanks, providing additional support and protection against potential leaks or failures.

- Q: How does fiberglass fabric compare to other fabric materials in terms of cost?

- The cost of fiberglass fabric can vary depending on several factors, including quality, thickness, and how it is used. In general, fiberglass fabric is usually more expensive than traditional fabrics like cotton or polyester. However, when compared to specialized industrial fabrics like Kevlar or carbon fiber, fiberglass fabric often provides a more affordable option. The reason for fiberglass fabric's affordability is mainly because it is widely available and produced at a relatively low cost. Moreover, the durability and long lifespan of fiberglass fabric can lead to cost savings in the long term, as it may require fewer replacements or repairs compared to other fabric materials. Overall, although fiberglass fabric may not be the most inexpensive fabric option, it is often considered a cost-effective choice for various applications.

- Q: Is fiberglass cloth antistatic?

- Fiberglass cloth itself is not static, also known as glass fiber glass fiber cloth geotextile, with tensile strength is very strong, the surface static electricity accumulation, no fouling dead angle, easy to clean

- Q: Is fiberglass fabric suitable for use in automotive interiors?

- Automotive interiors benefit greatly from the use of fiberglass fabric. This material is renowned for its durability, strength, and ability to withstand high temperatures and fires. These exceptional properties make it an excellent option for automotive interiors, where it can endure daily wear and tear and provide exceptional protection. In the automotive industry, fiberglass fabric is extensively utilized for various purposes. It serves as a reinforcement material for seats, headliners, door panels, and other interior components. Its remarkable tensile strength ensures that the fabric can withstand the pressure and stress placed on these parts, ensuring their longevity. Moreover, fiberglass fabric is commonly employed as a sound and heat insulator in automotive interiors. Its thermal characteristics help to reduce heat transfer, keeping the cabin cooler during hot weather. Additionally, it effectively dampens sound vibrations, resulting in a quieter and more comfortable driving experience. Furthermore, fiberglass fabric's resistance to moisture, mold, and mildew makes it an ideal choice for automotive interiors exposed to diverse weather conditions. It is also effortless to clean and maintain, which is vital for preserving the aesthetics and functionality of the interior components. In conclusion, fiberglass fabric offers a multitude of advantages that render it suitable for automotive interiors. Its strength, durability, heat resistance, and insulation properties make it a favored option among manufacturers and designers seeking to create top-notch, long-lasting, and comfortable automotive interiors.

- Q: With what glue can stick glass steel cans?

- The modified epoxy adhesive can stick to the FRP tank;In addition to the epoxy resin and other non-polar polyolefin plastic adhesive is not good, for all kinds of metal materials such as aluminum, steel, iron, copper; non metallic materials such as glass, wood and concrete; and thermosetting plastics such as phenolic, amino, unsaturated polyester has excellent adhesive properties, so it is called monengjiao. Epoxy adhesive is an important kind of structural adhesive.

- Q: Is fiberglass fabric resistant to tears and punctures?

- Fiberglass fabric is widely recognized for its exceptional ability to withstand tears and punctures. This can be attributed to the strength and durability of fiberglass, which is derived from delicate glass fibers. These fibers are intricately interwoven to produce a fabric that exhibits remarkable resistance against tearing and puncturing. Moreover, manufacturers often apply specialized coatings or finishes to fiberglass fabric, thus augmenting its tear and puncture resistance. Nevertheless, it is crucial to acknowledge that the precise degree of resistance may fluctuate based on the particular construction and caliber of the fiberglass fabric.

- Q: Can fiberglass fabric be used for making air ducts?

- Air ducts can be made using fiberglass fabric, which is a versatile material commonly found in various industries, including HVAC. This material provides several benefits when used in air duct applications. To begin with, fiberglass fabric is lightweight, making it easier to handle and install compared to alternative materials like sheet metal. This leads to faster and more cost-effective installation processes. Furthermore, fiberglass fabric is non-porous, meaning it resists moisture, mold, and mildew. This is especially important in air ducts as it helps maintain indoor air quality by preventing the growth of harmful bacteria and fungi. In addition, fiberglass fabric offers excellent thermal insulation properties, effectively retaining heat or cold air. This improves energy efficiency by reducing heat transfer and minimizing energy losses. Moreover, fiberglass fabric is known for its fire-resistant properties, making it a safe choice for air duct applications. It has a high melting point and does not emit toxic gases when exposed to fire, ensuring the safety of occupants in case of a fire incident. Lastly, fiberglass fabric is flexible and easily molded and shaped to fit different duct configurations, including bends and turns. This flexibility allows for easy customization and adaptation to various building layouts. Overall, fiberglass fabric is a suitable material for making air ducts due to its lightweight, non-porous, thermal insulation, fire-resistant, and flexible properties. However, it is important to ensure that the fiberglass fabric used for air ducts meets the necessary industry standards and regulations to ensure proper performance and safety.

Send your message to us

Sewing Fiberglass Fabric FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords