Fiberglass Fabrics - High Quality Fiberglass Fabric Cloth

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

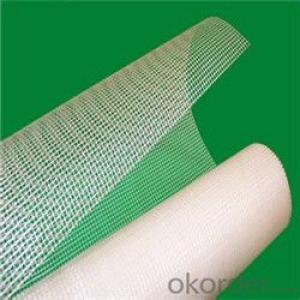

Introduction of Fiberglass Fabric Cloth:

Fiberglass fabric is weaved of high quality C-glass fibers or E-glass fibers.

Fiberglass fabric is a good construction material with the following excellent properties

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of Fiberglass Fabric Cloth

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

Packing of Fiberglass Fabric Cloth:

Fiberglass fabric is wound on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

Storage of Fiberglass Fabric Cloth:

Store rolls in a cool, dry location

Protect rolls from weather and other damage.

- Q: Is fiberglass fabric resistant to oil and grease?

- Yes, fiberglass fabric is generally resistant to oil and grease. Fiberglass has excellent chemical resistance properties, making it highly resistant to a wide range of oils and greases. This resistance is due to the non-reactive nature of fiberglass, which prevents the fabric from being degraded or damaged by contact with oil and grease. Additionally, fiberglass fabric is also resistant to many other chemicals, including acids, alkalis, and solvents, making it a versatile material in various industries where resistance to oil and grease is required. However, it is important to note that the level of resistance may vary depending on the specific type and quality of fiberglass fabric used. It is always recommended to consult the manufacturer or supplier for specific information on the resistance capabilities of the fiberglass fabric in question.

- Q: How does fiberglass fabric perform in insulation against sound?

- Fiberglass fabric is widely used in various applications including insulation against sound. It performs exceptionally well in reducing and absorbing sound waves due to its unique properties. The structure of fiberglass fabric consists of densely packed fibers, which helps in breaking down sound waves and reducing their transmission. As sound waves encounter the fabric, they are dispersed and absorbed by the fibers, preventing them from passing through to the other side. This absorption capability is crucial in creating a soundproof environment and reducing noise pollution. Furthermore, fiberglass fabric is known for its high density and low porosity. These properties contribute to its effectiveness in sound insulation. The dense structure of the fabric prevents sound waves from passing through, while the low porosity minimizes the amount of sound that can penetrate the fabric. This combination results in excellent soundproofing capabilities. Moreover, fiberglass fabric is a lightweight material, making it easy to install in various settings such as walls, ceilings, and floors. Its flexibility allows it to conform to different shapes and sizes, ensuring complete coverage and minimizing the risk of sound leakage. Additionally, fiberglass fabric is also known for its thermal insulation properties. This means that it not only helps in reducing sound transmission but also provides additional benefits by preventing heat transfer. This dual functionality is advantageous in applications where both soundproofing and temperature control are desired, such as in recording studios, theaters, or industrial settings. In summary, fiberglass fabric performs exceptionally well in insulation against sound. Its dense structure, low porosity, and absorption capabilities effectively reduce the transmission of sound waves. Its lightweight and flexible nature make it easy to install in various settings, while its thermal insulation properties provide additional benefits. Overall, fiberglass fabric is a reliable choice for soundproofing applications.

- Q: Can fiberglass fabrics be used for insulation in refrigeration systems?

- Yes, fiberglass fabrics can be used for insulation in refrigeration systems. Fiberglass is a common material used for insulation due to its excellent thermal properties. It is a lightweight and durable material that can effectively resist heat transfer, making it suitable for insulating refrigeration systems. Additionally, fiberglass fabrics can be easily molded or shaped to fit the specific needs of the refrigeration system, ensuring a proper and tight insulation. It is also resistant to moisture, which is important in refrigeration systems where condensation can occur. Overall, fiberglass fabrics are a reliable choice for insulating refrigeration systems and are commonly used in the industry.

- Q: Is fiberglass fabric resistant to termites?

- No, fiberglass fabric is not resistant to termites. Termites are known to feed on organic materials such as wood, paper, and fabric, and fiberglass fabric is not exempt from their feeding habits. While fiberglass fabric may not provide a suitable food source for termites, they can still cause damage to the fabric by chewing through it or using it as a pathway to reach other materials. Therefore, it is important to take appropriate measures to protect fiberglass fabric from termite infestation, such as using termite barriers, regular inspections, and treating the surrounding area for termites if necessary.

- Q: Does anyone know what kind of sculpture of glass fiber reinforced plastic sculpture is?

- Generally large items to see more, and are not particularly expensive. But it's more expensive than the average stone carving because you want to turn the mold and the clay.

- Q: Roof with a single group of waterproof coating and glass fiber cloth done, but the past is still in the seam water seepage, how should remediation?

- Now there are waterproof paint, not black, black is likely to be asphalt type, easy to brittle crackingNow there are chlorinated rubber class waterproof, and silicone waterproof, you buy when asked clearly type, and then mixed white cement modulation, brush more than a few times, anti cracking, waterproof prominent, can be directly built

- Q: Can fiberglass fabric be dyed or printed on?

- Yes, fiberglass fabric can be dyed or printed on. However, it is important to use specific dyes and printing techniques suitable for fiberglass to ensure proper adhesion and durability of the color or print.

- Q: Can fiberglass fabric be used for reinforcement in swimming pools?

- Yes, fiberglass fabric can be used for reinforcement in swimming pools. It is a durable and lightweight material that is commonly used in the construction and maintenance of pools to provide added strength and support.

- Q: How does fiberglass fabric perform in chemical exposure?

- Fiberglass fabric performs exceptionally well in chemical exposure. Due to its inherent resistance to a wide range of chemicals, it is commonly used in various industries where exposure to corrosive substances is expected. The fabric's composition, typically consisting of glass fibers woven together, provides a strong barrier against chemical attack and degradation. In many cases, fiberglass fabric can withstand exposure to acids, alkalis, solvents, and other corrosive chemicals without experiencing any significant damage or deterioration. This resistance to chemical attack makes it an ideal choice for applications such as chemical storage tanks, pipes, ducts, and equipment linings. Moreover, the fabric's non-reactive nature helps prevent contamination or leaching of chemicals into the surrounding environment, making it a safe and reliable option for handling hazardous substances. Additionally, fiberglass fabric's thermal insulation properties can further enhance its performance in chemical exposure by offering protection against extreme temperatures that may accompany certain chemical processes. However, it is important to note that the specific performance of fiberglass fabric in chemical exposure can vary depending on the type and concentration of the chemical, as well as the duration and temperature of exposure. Therefore, it is always recommended to consult with manufacturers or industry experts to ensure the suitability of fiberglass fabric for a particular application and to determine any necessary precautions or compatibility considerations.

- Q: Is fiberglass fabric durable?

- Yes, fiberglass fabric is known for its durability. It is a strong and resilient material that is designed to withstand high temperatures, harsh chemicals, and extreme weather conditions. It is resistant to abrasion, tearing, and impact, making it suitable for various applications where durability is required. Additionally, fiberglass fabric has a long lifespan and does not easily degrade or deteriorate over time.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Fabrics - High Quality Fiberglass Fabric Cloth

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords