Trustable Cuplock Scaffolding System with Best Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Ring-lock Scaffolding

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2.Main Features of Cup-lock Scaffolding

Each Cup-lock is welded on post every 0.6m. Choose step pitch based on mechanical requirementsWhen installing the scaffolding, insert ledger connector into the pole of the cup-lock, then hammer ledger connector to finish fastening.The more load, the more reliable fasten.Cup-lock Scaffolding has no special retaining member and no active parts. It’s easy and convenient to operation with integral low costs.

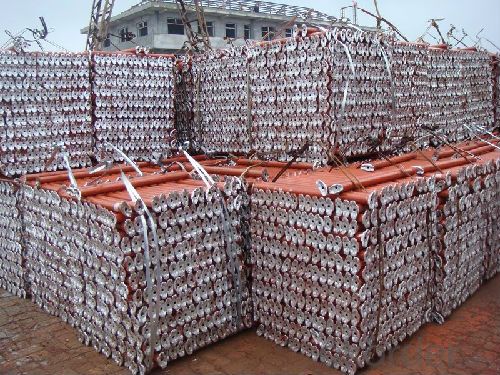

3.Cup-lock Scaffolding Images

4.Cup-lock Scaffolding Specification

A support system for construction, owns advantages of both cup-lock scaffolding and shoring tower.It is in the development direction of new type scaffolding.

It is widely used in buildings, bridges, tunnels etc.

5.FAQ OF Cup-lock Scaffolding

What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we

are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Ring-lock Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What is the retail price on a goldblatt scaffold?

- What exactly is this? I've never heard anything like this before?

- Q: What are the common signs of wear or damage on a steel tube coupler?

- Signs of wear or damage on a steel tube coupler can be identified through various indicators. These indicators include the presence of rust or corrosion on the coupler's surface, the occurrence of cracks or fractures in the metal, the deformation or bending of the coupler, and the absence or looseness of bolts or fasteners. Furthermore, if the coupler does not fit tightly onto the steel tube or if excessive play or movement is observed when the coupler is assembled, it may suggest wear or damage. To ensure proper assembly and connection, it is crucial to inspect the threads on the coupler, as threads that are worn or damaged can impede the assembly process. To maintain the structural integrity and safety of connections, it is imperative to regularly inspect and maintain steel tube couplers and promptly address any signs of wear or damage.

- Q: Are steel tube couplers reusable in scaffolding?

- Indeed, scaffolding can make use of reusable steel tube couplers. Known as scaffold fittings or scaffolding clamps, these couplers are fabricated to securely join steel tubes within scaffolding frameworks. Manufactured from top-grade steel, they possess the durability to withstand substantial loads and offer stability to the scaffolding system. The couplers can be effortlessly disassembled and reassembled, allowing for their reuse in various construction ventures or separate segments of the same project. However, it is vital to conduct a thorough inspection of the couplers for any signs of damage or wear prior to reuse to ensure the safety and dependability of the scaffolding structure.

- Q: Can steel tube couplers be used in scaffolding projects with curved structures?

- Yes, steel tube couplers can be used in scaffolding projects with curved structures. Steel tube couplers are versatile and can be used to connect steel tubes at various angles, including curved structures. They provide a strong and secure connection, ensuring the stability and safety of the scaffolding system. However, it is important to consider the specific requirements of the curved structure and select the appropriate size and type of coupler that can accommodate the curvature. Proper planning and design are crucial to ensure the scaffolding system can withstand the unique challenges posed by curved structures.

- Q: Are steel tube couplers compatible with modular scaffolding systems?

- Yes, steel tube couplers are compatible with modular scaffolding systems. They are commonly used to connect and secure the tubes and components of the scaffolding, allowing for a sturdy and safe structure.

- Q: Can steel tube couplers be used in scaffolding projects with complex structures?

- Scaffolding projects with intricate designs can utilize steel tube couplers. These couplers possess versatility, enabling the connection of tubes at different angles and facilitating the creation of personalized scaffolding structures. Their design ensures robust and secure connections, guaranteeing the stability and safety of the scaffolding system. Moreover, steel tube couplers exhibit durability and can withstand significant loads, making them suitable for supporting complex scaffolding structures. Nonetheless, it is crucial to install and use these couplers correctly, adhering to industry standards and guidelines to preserve the integrity and safety of the scaffolding system.

- Q: What is the difference between a putlog coupler and a right-angle coupler?

- Both a putlog coupler and a right-angle coupler serve as types of couplers in scaffolding systems, but they have distinct designs and purposes. Specifically designed for connecting a putlog or transom tube to a ledger or bearer, a putlog coupler ensures a secure connection with its single bolt, tightening the grip on the tubes. This type of coupler is commonly utilized in brickwork construction or when a transom is needed to support the platform. In contrast, a right-angle coupler is employed to join two tubes at right angles, creating a corner joint in the scaffold structure. With two bolts, this coupler fastens the tubes together securely, resulting in a strong and stable connection. Right-angle couplers are frequently employed when the scaffold requires a change in direction or when forming a corner support. In summary, the primary distinction between a putlog coupler and a right-angle coupler lies in their specific applications and the type of connections they facilitate. A putlog coupler connects a transom tube to a ledger or bearer, whereas a right-angle coupler connects two tubes at a right angle to form a corner joint.

- Q: What are the typical safety features of steel tube couplers?

- The typical safety features of steel tube couplers include high tensile strength, corrosion resistance, and secure locking mechanisms to prevent accidental disengagement. They are also designed to withstand extreme loads and provide stability and durability in various applications.

- Q: Can steel tube couplers be used in scaffolding projects with limited working space?

- Certainly, scaffolding projects with restricted working space can definitely utilize steel tube couplers. These couplers possess remarkable versatility and can effortlessly affix to steel tubes, establishing secure connections within scaffolding frameworks. They are available in diverse sizes and varieties, including swivel couplers, sleeve couplers, and putlog couplers, enabling adaptable configurations within cramped areas. These couplers offer dependable and robust connections, guaranteeing the stability and safety of the scaffolding system. Moreover, steel tube couplers are compact and necessitate no supplementary room for assembly or disassembly, making them exceptionally suitable for undertakings with limited working space.

- Q: What are the common safety regulations for using steel tube couplers in scaffolding?

- When using steel tube couplers in scaffolding, there are several safety regulations that must be followed to ensure worker safety and prevent accidents on construction sites. 1. Installation: Proper installation of steel tube couplers is essential. It involves securely fastening the couplers to the scaffolding tubes, following the manufacturer's instructions for a tight fit and proper alignment. 2. Load capacity: The load capacity of the steel tube couplers should be considered. It is important not to exceed the maximum load capacity and to regularly inspect the couplers for any signs of damage or wear that could affect their strength. 3. Inspections: Regular inspections should be conducted to identify any damage to the steel tube couplers, such as cracks or corrosion. Any damaged couplers should be replaced immediately to maintain the scaffolding's structural integrity. 4. Proper use: Steel tube couplers should only be used for their intended purpose, which is securely connecting scaffolding tubes. They should not be used in any other way that could compromise their stability and safety. 5. Fall protection: Workers using scaffolding should always wear appropriate fall protection equipment, including safety harnesses and lanyards. This is crucial for preventing falls from heights and ensuring worker safety. 6. Training and supervision: Workers using steel tube couplers in scaffolding should receive proper training on their correct usage and safety protocols. They should also be supervised by a qualified individual to ensure compliance with all safety regulations. By adhering to these common safety regulations, the risk of accidents and injuries related to the use of steel tube couplers in scaffolding can be significantly reduced. It is essential for all workers and supervisors to prioritize safety and take necessary precautions to create a secure working environment.

Send your message to us

Trustable Cuplock Scaffolding System with Best Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords