Frame Connected Scaffolding with Easy Storage and Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

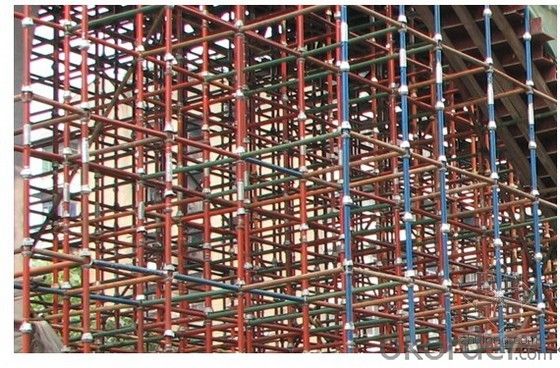

3. Images

4. Specification

Maximum breaking load: 22.2t

Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: so yesterday i had it pierced, surprisingly didn't hurt, even though she used freezing spray but yeah.but what i wanted to know was..1) how do i know what gauge it is? i know the bar is 38mm long the piercer gave me the packet it was in just in case i forgot, because i want to buy some barbells but i don't know what size to have? and the piercer said that i should go for a 36mm but i'm not sure, it doesn't seem to be big enough as it is. and the ball is about 4mm i think? dunno i used a ruler to measure it lmfao2) should i keep twisting it? i heard that you have to, to stop the skin growing over it but i read somewhere else that i shouldn't otherwise it will take longer to heal?3) to clean it, all i have done so far is rub around the pierced area with an ear bud, then like dunk it in a small tub of hot salty water for 5 minutes? is that enough? and should i use tea tree oil? and would i be able to use that even though i had it done not long ago?there might be more questions so keep checking:)

- 1. The chances are that it's going to be a 14g (1.6mm) 2. do not twist/play/move the jewelry! this is a BAD idea-- it will prolong healing time, destroy the fistula and bring in unwanted bacteria into the wound. 3. You can use tea tree oil, just make sure you dilute it in water beforehand. Keep doing the salt soaks and you should be fine, you can do them for 5-10 minutes so if you want to do them longer than 5 minutes, you can.

- Q: Are steel tube couplers compatible with different types of scaffolding stairs or access systems?

- Yes, steel tube couplers are typically compatible with different types of scaffolding stairs or access systems. Steel tube couplers are commonly used in scaffolding construction to connect tubes together, allowing for the creation of various scaffolding structures, including stairs and access systems. These couplers are designed to provide a secure and reliable connection between different scaffolding components, ensuring stability and safety. Whether it is a single or double coupler, swivel coupler, or sleeve coupler, they are generally designed to fit standard scaffolding tubes, which are commonly made of steel. However, it is important to ensure that the specific coupler being used is compatible with the type and size of the scaffolding stairs or access system being constructed. Different manufacturers may have variations in their coupler designs, so it is advisable to consult the product specifications or seek professional advice to ensure compatibility.

- Q: My neighbour has built scaffolding in my garden, I would be fine with it except it stops about halfway over my door.When i questioned what was going on the contractor said that they had permission to build it there but neither myself or my landlord have given permission.What can i do, I don't know who it is that is getting work done, i live in flats there are about 10 house next door, so i can't ask them to move it.

- If this is obstructing your access then you hae a right to have this moved tell your neighbour that you need to remove the scaffolding ..Also tell the contractor that you will need to see a copy of the permission that has been given .If none of this is available then ask them to remove the scaffolding then contact you land Lord as he will have the right to charge a fee for either the removal of the scaffolding or the time it is on his land and has the right to refuse permission to have it on his land

- Q: Are steel tube couplers resistant to UV radiation or sun exposure?

- Yes, steel tube couplers are resistant to UV radiation and sun exposure.

- Q: Single-row fastener steel scaffolding erection height should not exceed how much? The The Is it 25m or 20m? The The The The More

- Fidelity aluminum alloy gearbox is to adapt to the provisions of the national limit, specially developed a lightweight product to 12 files, for example, aluminum alloy cast iron weight than about 100KG, both performance exactly the same, aluminum High demand for road conditions

- Q: I had the scaffold piercing done around 8 weeks ago give or take.Im not sure if the piercer done it 100% correct. the upper part is fine - altho I have a small lump inside.But the lower part is in the thickest part of the ear. Its getting a layer of skin (small) over the bar now.Is this right?Also, it has a studio titanuim bar in at the moment, the top is really hurting and a bit swolen so I guess its getting infected? Ive ordered 2 standard rings to fit to try and heal by itsself (I had the bar put in right away)Is it ment to hurt that much after this long?

- Industrial piercings (or scaffolds, as you call it) can take upto a year to heal and in my experience are one of the biggest pains to heal for cartilage piercings. I've had one for 3 years and it still gets sore from time to time no matter what the jewelry. It gets just as sore when I'm wearing 2 rings as it does when I'm wearing one barbell. Are you sleeping on it at all? or bumping it? that is could be why it's hurting and swollen.. I am doubting its infected. Is there any green-ish discharge? That is one sign that it's infected. What are you doing for aftercare? Sea salt soaks work great for healing piercings, and the warm water also helps calm the piercing down. I have added a link on how to do that. If you change jewelry so soon you could just be irritating it more. It's still a pretty new piercing. If you doubt the piercer who pierced it, you could go to a new piercer and ask what they think about the placement and how it's healing.

- Q: Can steel tube couplers be used for scaffolding in marine or offshore environments?

- When using scaffolding in marine or offshore environments, it is important to consider certain factors. These environments are known for their harsh conditions, including exposure to saltwater, high humidity, and corrosive elements. Therefore, it is crucial to use steel tube couplers that are specifically designed and constructed to withstand these conditions. In marine or offshore environments, it is preferable to use stainless steel tube couplers due to their high resistance to corrosion. Stainless steel contains chromium, which creates a protective layer on the surface, preventing rust or corrosion. This makes it an ideal choice for scaffolding in these environments where exposure to saltwater and other corrosive elements is common. It is also important to regularly inspect and maintain the steel tube couplers used in marine or offshore scaffolding. This involves regular cleaning to remove any salt or corrosive substances that may have accumulated. Additionally, routine checks should be conducted to identify any signs of corrosion or damage. If any issues are identified, prompt repairs or replacements should be carried out to ensure the safety and integrity of the scaffolding structure. In conclusion, to ensure the durability and resistance to corrosion of steel tube couplers used in marine or offshore scaffolding, it is essential to use stainless steel couplers and adhere to proper maintenance practices. By doing so, scaffolding structures in these environments can be erected and maintained safely.

- Q: How do you ensure proper alignment and stability when using steel tube couplers in scaffolding?

- Proper alignment and stability when using steel tube couplers in scaffolding can be ensured by following a few key steps. Firstly, it is important to select high-quality steel tube couplers that meet industry standards and have the appropriate load capacity for the specific application. Secondly, before connecting the tubes, it is crucial to ensure that the ends of the tubes are clean and free from any debris or rust that could hinder a secure connection. Additionally, using a hammer or mallet to lightly tap the couplers into place can help ensure a tight fit. Finally, regularly inspecting the scaffolding for any signs of movement, loosening, or misalignment, and promptly addressing any issues can help maintain stability and prevent accidents.

- Q: I want to get a piercing before school starts (on the 17th). I'm getting it next Friday but I'm not sure which one would be better to get. Which one would be less sore/painful after 4 days? And my ears are really small and I have a super thick cartilage so would they still be able to pierce it / would there be a greater chance of infection if I get the industrial ? Help pleaseeee

- I have my belly button pierced and i would definatley go with that. Pretty much, the only pain for the bellybutton is getting it pierced then it doesnt hurt after (unless you hit it WHICH HURTS ALOT) it takes a while to heal but doesnt hurt and you can change it. I have my cartilage pierced and WOW. it hurt alot and it hurts for a longer time afterwards. The peircer may say you cant get your industrial if your ear is too small and if your cartilage is thick it will hurt alot more. personally i would say go with belly button., :)

- Q: I got a scaffold piercing 2 days ago, how long will it be swollen for?

- It sounds such as you have a contaminated piercing website. you will possibly desire to get a physician to look at this as there must be a situation. Are you specific that the kit that became used to pierce your ears have been thoroughly sparkling? If no longer, you will possibly have an infection from it. wish that this permits:)

Send your message to us

Frame Connected Scaffolding with Easy Storage and Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords