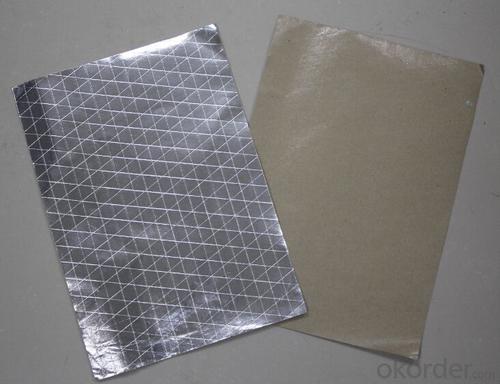

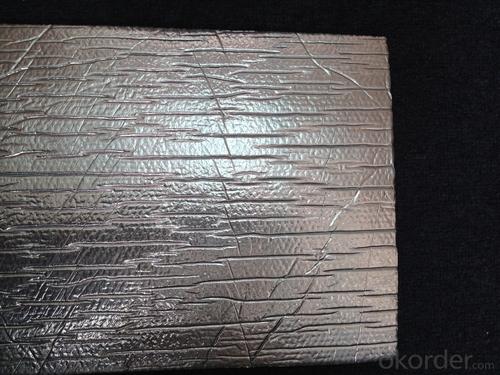

Fiberglass Facing Flexible Ducts Bubble Insulation Reflect

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Is it possible to utilize black fiberglass tissue in the construction of paper airplanes?

- <p>While black fiberglass tissue is not a typical material for making paper airplanes, it is technically possible to use it. However, it's important to note that fiberglass tissue is much stronger and less flexible than traditional paper, which might affect the flight characteristics of the airplane. Additionally, fiberglass can be abrasive and may not fold as cleanly, potentially leading to a less aerodynamic design. It's also heavier, which could impact the airplane's ability to fly effectively. For the best results in paper airplane construction, lightweight and flexible materials like standard paper or tissue paper are recommended.</p>

- Q: Is it possible to utilize black fiberglass tissue as an insulating material?

- <p>Yes, black fiberglass tissue can be used for insulation materials. It is a type of glass wool that provides thermal insulation, sound absorption, and fire resistance. The black color is typically due to the addition of colorants, which do not affect its insulating properties. However, it is important to note that fiberglass insulation, including black fiberglass tissue, should be handled with care due to potential health risks from inhaling fibers and should be installed in accordance with safety guidelines.</p>

- Q: Is it safe and practical to use black fiberglass tissues as diaper wipes for babies?

- <p>Black fiberglass tissues are not suitable for use as diaper wipes. Fiberglass can be abrasive and may contain chemicals that are harmful to the skin, especially for sensitive baby skin. It's important to use soft, gentle materials like cotton or specially designed baby wipes that are free from harsh chemicals to avoid skin irritation and potential health risks.</p>

- Q: What characteristics define black glass fiber cloth and what are its notable attributes?

- <p>Black glass fiber cloth is a type of fabric made from woven glass fibers, known for its high strength, heat resistance, and electrical insulation properties. It is resistant to chemicals and has a high melting point, making it suitable for use in harsh environments. This cloth is also non-flammable and has good UV resistance, which is why it's often used in applications where durability and safety are paramount. It's commonly used in the automotive, aerospace, and construction industries due to its ability to withstand high temperatures and protect against electrical hazards.</p>

- Q: What are the potential hazards and precautions one should be aware of when handling black fiberglass tissue?

- <p>Black fiberglass tissue can pose safety concerns due to its fibrous nature and potential to cause skin irritation, respiratory issues, and eye injuries. To mitigate these risks, it's crucial to wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator mask. Avoid inhaling dust or fibers, and ensure proper ventilation in the work area. Skin contact should be minimized, and any contact should be followed by thorough washing with soap and water. Dispose of the material according to local regulations to prevent environmental contamination.</p>

- Q: What is the production cost for black fiberglass tissues?

- <p>The cost to produce black fiberglass tissues varies and depends on several factors including the raw material costs, production scale, labor, energy consumption, and market demand. Fiberglass itself is made from silica sand, which is melted and spun into fine fibers. The addition of color, in this case, black, will add to the cost. However, without specific details on the production process, quantity, and current market prices for materials and labor, it's challenging to provide an exact figure. Generally, the cost can range from a few dollars to tens of dollars per square meter, but this is a rough estimate and actual costs may differ significantly.</p>

- Q: This question asks about the impact of black fiberglass tissue on the quality of air inside buildings.

- <p>Black fiberglass tissue, commonly used as insulation, can affect indoor air quality if not properly installed or if it becomes damaged. Fiberglass releases tiny glass fibers into the air, which can be inhaled and cause respiratory irritation, allergies, or even more severe health issues over time. Proper installation and sealing can minimize the release of these fibers. Additionally, ensuring good ventilation in buildings can help reduce the concentration of airborne fibers. It's also important to follow safety guidelines when handling fiberglass to prevent exposure.</p>

- Q: Can I repurpose old black fiberglass tissues for cleaning purposes?

- <p>Yes, you can use your old black fiberglass tissues to make cleaning cloths or wipes. Fiberglass tissues are durable and can effectively pick up dirt and grime. However, it's important to ensure that the tissues are clean and free from any contaminants before repurposing. Cut them into desired sizes and use them for general cleaning tasks. Be cautious with the edges as fiberglass can be sharp. Always handle with care and consider wearing gloves to avoid irritation or injury.</p>

- Q: This question asks for the steps and considerations to properly install black fiberglass tissue to ensure its effectiveness and longevity.

- <p>To install black fiberglass tissue effectively and ensure its durability, follow these steps: 1) Clean the surface to be covered thoroughly to remove any dirt or debris. 2) Cut the fiberglass tissue to the required size, ensuring it fits snugly over the surface. 3) Apply a suitable adhesive, such as epoxy resin, to the surface and fiberglass tissue, following the manufacturer's instructions. 4) Press the fiberglass tissue firmly onto the surface, smoothing out any wrinkles or air bubbles. 5) Apply a protective layer of resin over the tissue to seal and protect it. 6) Allow the adhesive to cure fully as per the manufacturer's recommendations. 7) Regularly inspect and maintain the fiberglass tissue to prevent damage and prolong its lifespan.</p>

- Q: This question asks whether black fiberglass tissue can be recycled multiple times.

- <p>Black fiberglass tissue can be recycled, but its recyclability diminishes with each cycle due to the degradation of its physical properties. The first recycling process is usually the most effective, and subsequent recyclings result in a material of lower quality. Fiberglass, being a composite material, faces challenges in the recycling process because it combines glass fibers with plastic resins. While some industries may reuse fiberglass for specific purposes, it's not typically recycled multiple times like some other materials due to the loss in strength and structural integrity.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Insulation Reflect

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords