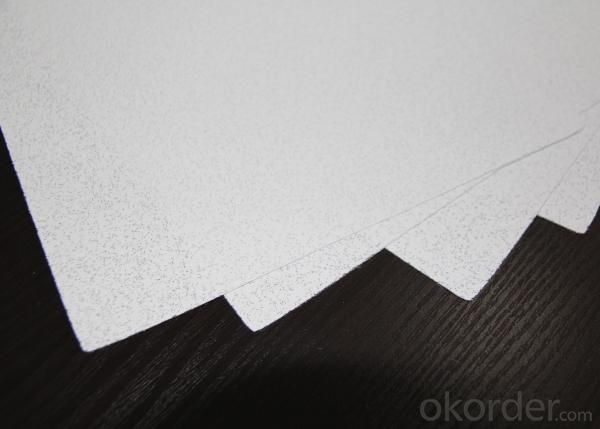

Fiberglass Facing White Spray Coating Tissue 700#-W

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 30000M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Spray Coating Tissue

700W

|

Specification | ||

|

ITEM |

UNIT |

VALUE |

|

Weight |

g/m2 |

380 |

|

Thickness |

mm |

0.55 |

|

Property ofFire Retardant |

|

Non-ignitability A level |

|

Tensile Strength MD |

n/5cm |

150 |

|

Tensile Strength CMD |

n/5cm |

110 |

SIZE:

Width: 0.6m---1.3m

Length: 50m-300m

Core I.D.: 3"(76mm ±1)

Based on order, special sizes are also available.

MSDS:No harm for body and environment, non-volatile product.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: ±0.5%.

3. The products should be stored at room temperature, kept from wet and kept away heat source.

4. Good appearance without stain, oxidation, mildew.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

Usage/Applications of Spraying Coating Tissue

Fiberglass facing is good at fireproof, mildew resistant, damp proof and strong air permeability. After laminated with glass wool or rock wool, the physical properties is excellent such as heat preservation, noise elimination, fire retardant, extinction, etc.

Packaging & Delivery of Spraying Coating Tissue

Each roll is packed by water-proof film

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing black glass fiber in construction projects.

- <p>Black glass fiber offers several advantages in construction, such as high strength and durability, making it ideal for reinforcement. It is also resistant to corrosion and has excellent electrical insulation properties. Additionally, it is lightweight, which can reduce the overall weight of structures. However, it has some disadvantages, including its brittleness, which can lead to breakage under certain conditions. Black glass fiber can also be harmful to health if inhaled, necessitating proper handling and safety measures. Moreover, it is not as flexible as some other materials, which may limit its use in certain applications.</p>

- Q: This question asks for methods to properly maintain and care for black fiberglass tissue to ensure its longevity and appearance.

- <p>To maintain black fiberglass tissue, follow these steps: Regularly clean the surface with mild soap and water to remove dirt and grime. Avoid using harsh chemicals or abrasive cleaners that can damage the surface. Periodically inspect for any signs of wear or damage and address them promptly to prevent further deterioration. Apply a UV-resistant sealant or coating to protect the fiberglass from sun damage, which can cause fading and weakening over time. Store the tissue in a cool, dry place when not in use to prevent moisture damage. Regular maintenance will help preserve the color and integrity of the black fiberglass tissue.</p>

- Q: This question asks for an explanation of the various methods used in the manufacturing process to produce black fiberglass tissue.

- <p>Black fiberglass tissue is typically produced through a series of manufacturing processes that involve the use of glass fibers and resins. The primary methods include: 1) The wet lay-up process, where glass fibers are soaked in a resin solution and then layered to form the tissue. 2) The spray-up process, where resin and chopped glass fibers are sprayed onto a mold and allowed to cure. 3) The hand lay-up process, which is similar to wet lay-up but involves manually applying the resin and fibers. 4) The pultrusion process, where fibers are pulled through a resin bath and then into a heated die to form the desired shape. 5) The filament winding process, where continuous glass fibers are wound around a rotating mandrel to create a strong, uniform tissue. Each method has its own advantages and is chosen based on the specific requirements of the end product, such as strength, flexibility, and cost.</p>

- Q: The user is asking if they can use old dryer sheets with black fiberglass tissues to enhance their performance.

- <p>Using old dryer sheets with black fiberglass tissues is not recommended as it may not improve their performance and could potentially cause damage. Dryer sheets are designed to reduce static and soften fabrics in laundry, and their chemicals may not be suitable for fiberglass tissues. Instead, consider using products specifically designed for cleaning and maintaining fiberglass to ensure their longevity and optimal performance.</p>

- Q: Is it possible to recycle black fiberglass tissue with ease?

- <p>Recycling black fiberglass tissue is not as straightforward as recycling other materials due to its unique composition and color. The black dye can interfere with the recycling process, making it difficult to recycle like standard fiberglass. Specialized facilities are required to handle the recycling of black fiberglass, and it's often not accepted in standard curbside recycling programs. Therefore, while it is technically recyclable, it is not easily recyclable in the conventional sense and requires specific processes and facilities.</p>

- Q: This question asks for the typical cost range of high-quality black fiberglass tissues, which are materials used in various industries.

- <p>The price range for high-quality black fiberglass tissues can vary significantly based on factors such as the manufacturer, thickness, and specific application requirements. Generally, the cost can range from $1 to $10 per square meter for standard grades, while more specialized or high-performance grades may cost between $10 to $50 per square meter. It's important to note that these prices are approximate and can fluctuate due to market conditions, availability, and the quantity purchased. For precise pricing, it's best to contact suppliers directly or check current market listings.</p>

- Q: Is it possible to utilize black fiberglass tissue as an insulating material in construction?

- <p>Yes, black fiberglass tissue can be used for building insulation. It is a type of insulation material known for its thermal and acoustic insulation properties. Black fiberglass is made from glass fibers and is often used in construction for insulating walls, roofs, and floors. It helps to reduce heat transfer, thereby improving energy efficiency and comfort within the building. However, it's important to note that proper installation and safety precautions are necessary due to the potential health risks associated with fiberglass, such as skin and respiratory irritation.</p>

- Q: Can I produce my own brand of black fiberglass tissues domestically?

- <p>Creating your own brand of black fiberglass tissues at home is challenging due to the specialized equipment and materials required. Fiberglass is made from fine fibers of glass, which are combined with a resin to harden. This process typically involves high temperatures and controlled environments that are not easily replicated at home. Instead, consider partnering with a manufacturing facility or purchasing from a supplier.</p>

- Q: This question asks about the environmental effects of utilizing black fiberglass tissue.

- <p>The use of black fiberglass tissue can have several environmental impacts. It is often used in construction and insulation, which can reduce energy consumption and lower greenhouse gas emissions. However, the production process can be energy-intensive and may release pollutants. Additionally, black fiberglass tissue can contribute to urban heat island effect due to its dark color, which absorbs more heat. Proper disposal is crucial as improper disposal can lead to environmental contamination. Overall, while it has benefits in insulation, the environmental impact must be managed through sustainable production and disposal practices.</p>

- Q: Is it possible to utilize black fiberglass tissue as a material for creating a floor mat?

- <p>Yes, you can use black fiberglass tissue to make a floor mat. Fiberglass is known for its strength and durability, making it a suitable material for various applications, including floor mats. However, it's important to ensure that the mat is properly treated to be non-slip and comfortable to walk on. Fiberglass can be abrasive and may not provide the softness or cushioning that some users prefer. Additionally, consider the aesthetic appeal and whether the black color is appropriate for your intended use. Always follow safety guidelines when working with fiberglass to avoid skin and respiratory irritation.</p>

1. Manufacturer Overview

| Location | Jangsu, China |

| Year Established | 1999 |

| Annual Output Value | Above US$0.3 billion |

| Main Markets | 0.00% Mid East 15.00% Northern Europe 15.00% North America 10.00% Eastern Asia 20.00% Africa 0.00% Eastern Europe 20.00% Southeast Asia 0.00% Oceania 0.00% Western Europe 0.00% Southern Europe 0South east asia;North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Facing White Spray Coating Tissue 700#-W

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 30000M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords