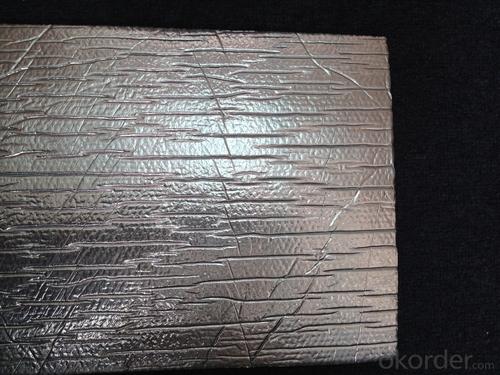

Fiberglass Facing Flexible Ducts Bubble Foil Green Foil Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: This question asks for environmentally friendly methods to dispose of old black fiberglass tissues.

- <p>To dispose of old black fiberglass tissues without harming the environment, follow these steps: First, check your local waste disposal regulations as they may have specific guidelines for hazardous materials. If fiberglass is considered hazardous in your area, contact a professional waste disposal service that specializes in hazardous waste. If not, you can dispose of it in a designated landfill or recycling facility. Avoid burning the tissues as it can release toxic fumes. Always handle the tissues with gloves to protect your skin and avoid inhaling fibers. Encourage recycling when possible, as this can reduce the environmental impact.</p>

- Q: What is the texture or appearance of the surface of black fiberglass tissue?

- <p>The surface finish of black fiberglass tissue is typically smooth and matte. It is characterized by a uniform, non-reflective appearance with a slight texture that is often associated with the woven nature of the fiberglass. This finish can vary slightly depending on the specific manufacturing process and the intended application of the fiberglass tissue.</p>

- Q: What is the chemical stability of black fiberglass tissue, and how does it react to various chemicals?

- <p>Black fiberglass tissue, which is a type of composite material made from glass fibers and a resin matrix, typically exhibits good chemical stability. It is resistant to many chemicals, including alkalis, acids, and salts, making it suitable for various industrial applications. However, it may not be as stable against strong acids or bases over extended periods. The stability can also be influenced by the specific type of resin used in the fiberglass, with some resins offering better resistance to certain chemicals than others. It's important to consult the material data sheet for specific information on chemical resistance for the black fiberglass tissue in question.</p>

- Q: Is it possible to use black fiberglass tissue as an insulating material for the roofs of residential homes?

- <p>Yes, black fiberglass tissue can be used for roof insulation in residential homes. It is a type of insulation material that provides thermal resistance, helping to reduce heat transfer and maintain a comfortable indoor temperature. Black fiberglass is also known for its durability and resistance to moisture, which can be beneficial in various climates. However, it's important to note that proper installation and ventilation are crucial for its effectiveness and to prevent any potential health risks associated with fiberglass.</p>

- Q: Is the use of black fiberglass scraps considered safe in construction projects?

- <p>The use of black fiberglass scraps in construction work is generally not recommended due to safety and quality concerns. Black fiberglass scraps may contain impurities and inconsistencies that can compromise the structural integrity of the construction. Additionally, they can pose health risks due to the inhalation of fiberglass particles, which can cause respiratory issues. It's crucial to use high-quality, undamaged materials that meet safety standards to ensure the safety of both the construction workers and the longevity of the construction project.</p>

- Q: How does fiberglass facing improve insulation?

- Fiberglass facing improves insulation by acting as a barrier that reduces heat transfer through conduction and radiation. It helps to trap air pockets within the insulation, enhancing its ability to resist heat flow. Additionally, the facing can provide a vapor barrier, preventing moisture from seeping into the insulation and compromising its effectiveness.

- Q: What is the standard thickness measurement for black fiberglass paper towels?

- <p>The thickness of black fiberglass paper towels can vary depending on the manufacturer and the specific product. Generally, these towels are known for their durability and thickness compared to standard paper towels. However, without a specific product reference, it's challenging to provide an exact measurement. Typically, they might range from 0.1 to 0.5 millimeters in thickness, but for precise information, one should refer to the product specifications or contact the manufacturer directly.</p>

- Q: Can fiberglass facing be recycled?

- Yes, fiberglass facing can be recycled.

- Q: Is there a specific kind of black fiberglass tissue that is safe and appropriate for use by infants and young children?

- <p>There isn't a specific type of black fiberglass tissue designed for babies and young children. Fiberglass tissues are not recommended for use on children's skin due to the potential for skin irritation and respiratory issues. Instead, for babies and young children, it's best to use soft, hypoallergenic tissues that are gentle on the skin. Always check the product labels for safety and suitability for children.</p>

- Q: Can fiberglass facing be used in high-temperature applications?

- No, fiberglass facing should not be used in high-temperature applications as it is not designed to withstand extreme heat and may melt or degrade.

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Foil Green Foil Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords