Fiberglass Facing Mat for Road Protection - Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Mat/ Fiberglass Mat for Road Protection Wholesale Price

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

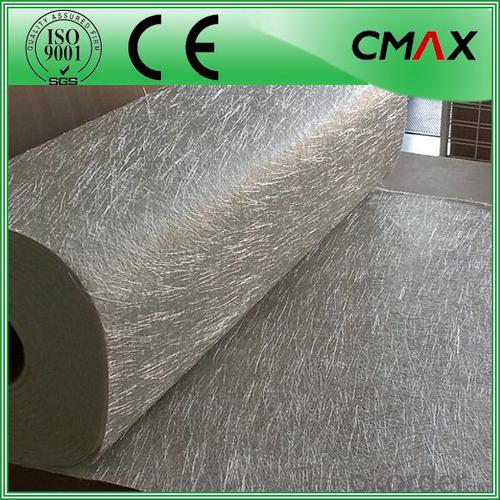

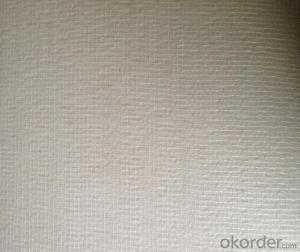

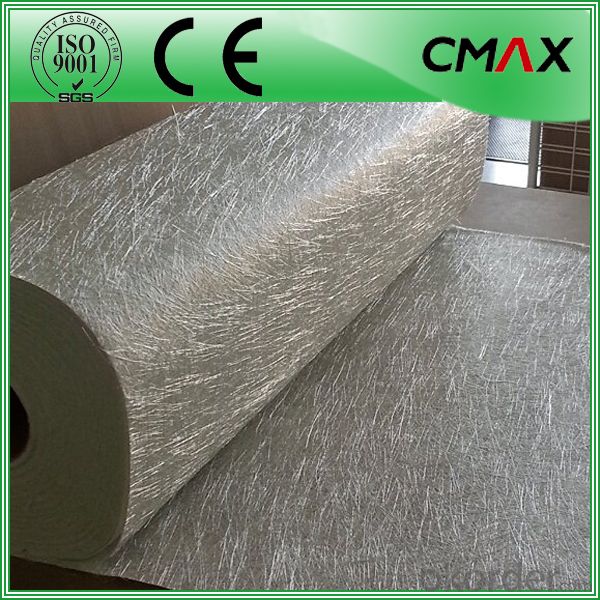

Products Shows:

Certificates:

- Q: Is it possible to use black fiberglass tissue for the purpose of insulating exterior walls?

- <p>Yes, black fiberglass tissue can be used for exterior wall insulation. It is a popular material due to its lightweight, high strength, and excellent thermal insulation properties. Black fiberglass tissue reflects solar radiation, which can help reduce heat absorption and improve the energy efficiency of buildings. However, it's important to ensure proper installation and consider the local climate and building codes, as some regions may have specific requirements for insulation materials.</p>

- Q: Is it possible to use black fiberglass tissue as a flooring material for a garden or patio?

- <p>Yes, you can use black fiberglass tissue to make flooring for your garden or patio. Fiberglass is known for its durability and resistance to weather, making it a suitable choice for outdoor applications. It's lightweight, easy to install, and can be used in combination with other materials like resin for a more solid and stable surface. However, it's important to ensure that the fiberglass is treated to be resistant to UV rays to prevent degradation over time. Always follow the manufacturer's guidelines for installation and maintenance to ensure the longevity and safety of your flooring.</p>

- Q: What is the texture or appearance of the surface of black fiberglass tissue?

- <p>The surface finish of black fiberglass tissue is typically smooth and matte. It is characterized by a uniform, non-reflective appearance with a slight texture that is often associated with the woven nature of the fiberglass. This finish can vary slightly depending on the specific manufacturing process and the intended application of the fiberglass tissue.</p>

- Q: Is it possible to utilize black fiberglass scraps in the creation of new products made from recycled materials?

- <p>Yes, you can use black fiberglass scraps to make new products from recycled materials. Fiberglass recycling is possible, and it involves processes like shredding and grinding the scraps to create a material that can be used in new products. This can include composites for construction, automotive parts, or even as a filler material. However, it's important to note that recycling fiberglass can be challenging due to its composite nature, and not all types of fiberglass are easily recyclable. Proper recycling facilities and methods are required to ensure the process is both effective and environmentally friendly.</p>

- Q: This question asks for a comparison between two types of insulation materials: glass fiber and ceramic fiber, highlighting their distinct characteristics and differences.

- <p>Glass fiber and ceramic fiber insulation materials differ in composition, properties, and applications. Glass fiber is made from glass and is known for its high tensile strength, flexibility, and resistance to moisture. It's commonly used in construction and automotive industries. Ceramic fiber, on the other hand, is made from ceramic materials and is characterized by high-temperature resistance, low thermal conductivity, and excellent chemical stability. It's often used in high-temperature industrial applications and aerospace. Additionally, ceramic fiber is generally more expensive than glass fiber due to its superior heat resistance and durability.</p>

- Q: Is it possible to recycle black fiberglass tissue in landfills?

- <p>Black fiberglass tissue, like other types of fiberglass, is not typically recycled in landfills. Landfills are not designed for recycling, but rather for the disposal of waste. Fiberglass is a composite material that is difficult to recycle due to its complex composition and the presence of resins that can make it challenging to separate the glass fibers from other components. Specialized recycling facilities are required to process fiberglass, and even then, the recycling process can be energy-intensive and costly. Therefore, black fiberglass tissue is usually not recycled in landfills and is instead disposed of as solid waste.</p>

- Q: What is the rate at which black fiberglass tissue absorbs moisture?

- <p>The moisture absorption rate of black fiberglass tissue is typically very low, often less than 1%. This low absorption rate is due to the material's hydrophobic nature and the manufacturing process that includes a resin treatment. However, specific absorption rates can vary depending on the exact composition and treatment of the fiberglass tissue, and it's advised to refer to the manufacturer's specifications for precise data.</p>

- Q: Is it possible to utilize black fiberglass tissues for domestic cleaning purposes?

- <p>Black fiberglass tissues are not typically recommended for household cleaning tasks. Fiberglass, especially when in a loose or frayed state, can be abrasive and may scratch surfaces. It can also leave behind fibers that are difficult to remove. For cleaning, it's better to use materials specifically designed for the purpose, such as microfiber cloths, which are gentle on surfaces and effective at picking up dirt and dust without scratching.</p>

- Q: Can fiberglass facing be recycled?

- Yes, fiberglass facing can be recycled.

- Q: Can I produce my own brand of black fiberglass tissues domestically?

- <p>Creating your own brand of black fiberglass tissues at home is challenging due to the specialized equipment and materials required. Fiberglass is made from fine fibers of glass, which are combined with a resin to harden. This process typically involves high temperatures and controlled environments that are not easily replicated at home. Instead, consider partnering with a manufacturing facility or purchasing from a supplier.</p>

Send your message to us

Fiberglass Facing Mat for Road Protection - Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords