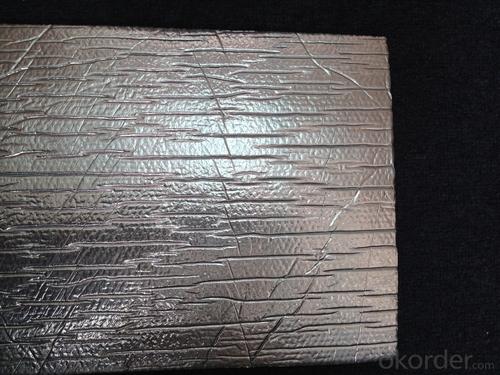

Fiberglass Facing Flexible Ducts Bubble Aluminum

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Does fiberglass facing require regular maintenance?

- No, fiberglass facing does not require regular maintenance. Fiberglass is a durable material that is resistant to many environmental factors, such as moisture, UV rays, and pests. It does not rust, rot, or decay like other materials, which means it does not need to be painted or sealed regularly. However, it is important to keep the fiberglass facing clean and free from dirt or debris to maintain its appearance and performance. Regular cleaning with a mild detergent and water should be sufficient to keep it in good condition. Additionally, if any damage or cracks occur in the fiberglass facing, it should be repaired promptly to prevent further issues. Overall, fiberglass facing is a low-maintenance option that can last for many years with minimal care.

- Q: This question asks about the ease of cleaning black fiberglass tissue.

- <p>Black fiberglass tissue is relatively easy to clean, but it requires some care. It can be wiped down with a damp cloth and mild detergent to remove dirt and grime. However, avoid using harsh chemicals or abrasive materials as they can damage the surface. Regular cleaning helps maintain its appearance and longevity. It's also important to dry the surface thoroughly after cleaning to prevent any water damage or mold growth.</p>

- Q: What is the chemical stability of black fiberglass tissue, and how does it react to various chemicals?

- <p>Black fiberglass tissue, which is a type of composite material made from glass fibers and a resin matrix, typically exhibits good chemical stability. It is resistant to many chemicals, including alkalis, acids, and salts, making it suitable for various industrial applications. However, it may not be as stable against strong acids or bases over extended periods. The stability can also be influenced by the specific type of resin used in the fiberglass, with some resins offering better resistance to certain chemicals than others. It's important to consult the material data sheet for specific information on chemical resistance for the black fiberglass tissue in question.</p>

- Q: What is the tensile strength of black fiberglass tissue?

- <p>The tensile strength of black fiberglass tissue can vary depending on the specific type and manufacturing process. Generally, it ranges from 500 to 3000 MPa (or 72,500 to 435,000 psi). This high tensile strength makes it suitable for applications requiring high strength-to-weight ratios, such as in construction, automotive, and aerospace industries. It's important to note that the exact tensile strength should be obtained from the manufacturer's specifications for the specific product in question.</p>

- Q: Is it possible to utilize recycled fiberglass insulation in the production of new insulation products?

- <p>Yes, recycled fiberglass insulation can be used to make new insulation products. The process involves collecting and recycling old fiberglass insulation, which is then cleaned, shredded, and reprocessed into new insulation materials. This not only reduces waste but also conserves resources. However, it's important to ensure that the recycling process meets safety and quality standards to maintain the performance and integrity of the new insulation products.</p>

- Q: Roof waterproof general use of what materials

- 1. EPDM rubber waterproofing membrane: cold sticky or self-adhesive method. 2. Chlorinated polyethylene waterproofing membrane: cold sticky method. 3. PVC waterproofing membrane: cold sticky method. 4. Chlorinated polyethylene - rubber blend waterproofing membrane: cold sticky method. 5. EPDM - polyethylene blend waterproofing membrane: cold sticky method. 6. Polyurethane waterproof coating: reactive cold construction. 7. Acrylic waterproof coating: cold construction, can be scraping, can be, can be sprayed, but the construction temperature needs to be higher than 4 ℃ when the film.

- Q: This question asks for methods to properly store and transport black fiberglass tissue, a material that requires careful handling to maintain its integrity.

- <p>To effectively store and transport black fiberglass tissue, ensure the following: Store the tissue in a cool, dry place away from direct sunlight to prevent degradation. Use airtight containers or wrappings to protect it from moisture and dust. When transporting, use a clean, dry vehicle and avoid stacking heavy items on top to prevent compression damage. Secure the material to prevent shifting during transit. Handle the tissue with clean, dry hands or gloves to avoid contamination. Always follow the manufacturer's guidelines for specific storage and transport recommendations.</p>

- Q: The user is inquiring if black fiberglass tissues can be used to create homemade cleaning products such as wipes or cloths.

- <p>Yes, you can use black fiberglass tissues to make your own cleaning products like wipes or cloths. Fiberglass tissues are durable and have good absorbency, making them suitable for cleaning purposes. However, it's important to ensure that the fibers are not too abrasive, as they could scratch surfaces. Additionally, consider the environmental impact and the safety of using fiberglass, as inhalation of fibers can be harmful. Always handle with care and use appropriate protective measures.</p>

- Q: This question asks for the steps and considerations to properly install black fiberglass tissue to ensure its effectiveness and longevity.

- <p>To install black fiberglass tissue effectively and ensure its durability, follow these steps: 1) Clean the surface to be covered thoroughly to remove any dirt or debris. 2) Cut the fiberglass tissue to the required size, ensuring it fits snugly over the surface. 3) Apply a suitable adhesive, such as epoxy resin, to the surface and fiberglass tissue, following the manufacturer's instructions. 4) Press the fiberglass tissue firmly onto the surface, smoothing out any wrinkles or air bubbles. 5) Apply a protective layer of resin over the tissue to seal and protect it. 6) Allow the adhesive to cure fully as per the manufacturer's recommendations. 7) Regularly inspect and maintain the fiberglass tissue to prevent damage and prolong its lifespan.</p>

- Q: What are the recommended brands for black fiberglass tissue used in various applications?

- <p>There isn't a universally recommended brand for black fiberglass tissue as the choice often depends on specific application needs, quality requirements, and regional availability. However, some well-known brands in the composite materials industry that offer fiberglass tissues include Owens Corning, Hexcel, and SGL Group. These companies are recognized for their high-quality products and have a broad range of applications in industries such as aerospace, automotive, and construction. It's advisable to consider factors like product specifications, cost, and customer reviews when selecting a brand for black fiberglass tissue.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Aluminum

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords