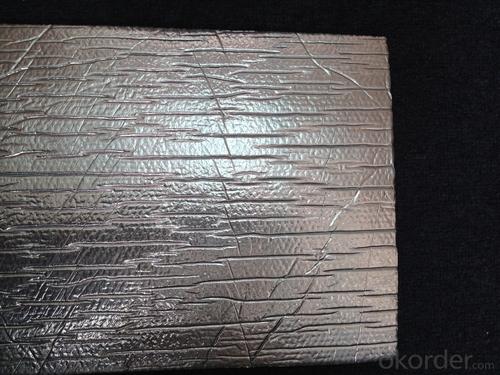

Fiberglass Facing Flexible Ducts Bubble Aluminum Green On Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Is it possible to utilize black fiberglass tissue in caravans or tents?

- <p>Yes, you can use black fiberglass tissue in your caravan or tent. It is often used for insulation and reinforcement due to its heat resistance and strength. However, it's important to ensure that it is installed correctly to avoid any potential health risks associated with inhaling fiberglass particles. Always follow safety guidelines and use appropriate protective equipment when handling fiberglass materials.</p>

- Q: Is it possible to use black fiberglass tissue as an insulating material within walls?

- <p>Yes, black fiberglass tissue can be used for insulation in walls. It is a type of fiberglass insulation that is often used in residential and commercial buildings due to its effectiveness in reducing heat transfer and providing thermal insulation. Black fiberglass tissue is made from glass fibers and has a high resistance to heat flow, which helps to maintain a comfortable temperature inside the building. It is also known for its durability and resistance to moisture, making it a popular choice for wall insulation. However, it's important to follow proper installation procedures and safety precautions to ensure the insulation's effectiveness and to protect against potential health risks associated with fiberglass.</p>

- Q: What is the tensile strength of black fiberglass tissue?

- <p>The tensile strength of black fiberglass tissue can vary depending on the specific type and manufacturing process. Generally, it ranges from 500 to 3000 MPa (or 72,500 to 435,000 psi). This high tensile strength makes it suitable for applications requiring high strength-to-weight ratios, such as in construction, automotive, and aerospace industries. It's important to note that the exact tensile strength should be obtained from the manufacturer's specifications for the specific product in question.</p>

- Q: What is the glass fiber needle felt dust filter bag

- The fibrous web is reinforced by a felt-like nonwoven fabric filter material. Hangzhou Xiao Yang, yes

- Q: What benefits does black fiberglass offer as an insulation material?

- <p>Black fiberglass insulation has several advantages. It provides excellent thermal insulation, reducing heat transfer and conserving energy. The material is also resistant to moisture and mold, which is crucial for maintaining a healthy indoor environment. Black fiberglass is lightweight, making it easy to handle and install. Additionally, it has high durability and can withstand various environmental conditions, ensuring a long service life. It also offers sound absorption properties, contributing to a quieter living or working space.</p>

- Q: Is fiberglass facing fire-resistant?

- Yes, fiberglass is considered fire-resistant. It is made from a combination of glass fibers and resin, which gives it excellent heat resistance properties. Fiberglass can withstand high temperatures without melting or releasing toxic fumes. It is often used in applications where fire resistance is important, such as insulation, protective clothing, and construction materials. However, it's important to note that while fiberglass itself is fire-resistant, the materials it is used with, such as adhesives or coatings, may affect its fire-resistance properties.

- Q: What are the ecological effects associated with the utilization of black fiberglass tissue?

- <p>The environmental impact of using black fiberglass tissue is primarily associated with its production and disposal. During production, it can release harmful chemicals and particulates into the air, contributing to air pollution. Additionally, fiberglass is not biodegradable, which means it persists in landfills and can leach chemicals into the soil and groundwater, potentially harming ecosystems. The dark color of black fiberglass may also absorb more heat, which could contribute to the urban heat island effect. However, it's important to note that the environmental impact can be mitigated through proper waste management and recycling programs, which are becoming more prevalent as awareness of environmental issues grows.</p>

- Q: What safety measures should be considered when using black fiberglass tissues in a baby's room?

- <p>When using black fiberglass tissues in a baby's room, it's crucial to ensure that the fibers are not inhaled by the baby, as they can be harmful. Always ventilate the room well to disperse any airborne fibers. Avoid using these tissues if the baby is present, and clean up any mess immediately to prevent the baby from coming into contact with the fibers. It's also important to wash hands thoroughly after handling fiberglass tissues to prevent the transfer of fibers to the baby. If possible, consider using alternative materials that are safer for a baby's environment.</p>

- Q: This question asks for the ability of black fiberglass tissue to resist moisture.

- <p>Black fiberglass tissue is known for its excellent moisture resistance. It is designed to repel water and prevent moisture absorption, which makes it ideal for applications where water or humidity is a concern. The moisture resistance of black fiberglass tissue is primarily due to its chemical composition and the manufacturing process that incorporates a resin system which creates a barrier against water penetration. This characteristic is crucial in industries such as construction, automotive, and aerospace where materials need to perform well in damp or wet environments without degrading.</p>

- Q: Can fiberglass facing be recycled?

- Certainly, it is feasible to recycle fiberglass facing. Fiberglass, composed of delicate glass fibers, is a reinforced plastic. Typically, the facing consists of a thin layer of fiberglass. Recycling fiberglass can be more intricate compared to other materials due to its distinctive properties. Nonetheless, recycling it remains possible. The recycling procedure entails shredding or grinding the fiberglass material into small fragments, which can then be utilized in the production of new items. However, it is vital to acknowledge that the recycling infrastructure for fiberglass might not be as widespread or easily accessible as it is for other materials. Therefore, it is advisable to consult local recycling facilities or specialized fiberglass recycling companies to ascertain the specific recycling options obtainable in your vicinity.

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Aluminum Green On Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords