Fiberglass Facing Black Fiberglass Tissue for Glasswool-65EP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction of Fiberglass Tissue

Fiberglass Tissue is a kind of facing, which is made of by the white fiberglass tissue, and special production process.

Application of Fiberglass Tissue

Our black tissue are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also fiberglass tissue facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Fiberglass Tissue

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Fiberglass Tissue

1. Waterproof paper then PVC shrinking Film

2. Water-Proof film only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

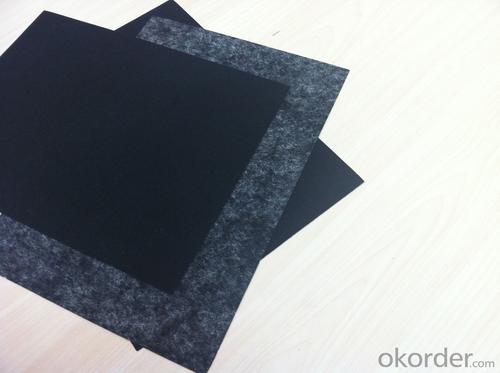

Pictures of Fiberglass Tissue

Specification of Fiberglass Tissue

Specification | ||

ITEM | UNIT | VALUE |

Type | C | |

Weight | g/m2 | 65±5 |

Thickness | mm | 0.40 |

Tensile Strength MD | n/125px | ≥130 |

Tensile Strength XD | n/125px | ≥90 |

Fiber Diameter | µ | 9 |

Fire Resistant Property | B1 | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: This question asks about the methods used by manufacturers to maintain the quality of black fiberglass tissue during the manufacturing process.

- <p>Manufacturers ensure the quality of black fiberglass tissue during production through several key steps. They start with high-quality raw materials, such as virgin glass fibers and resins, to ensure strength and durability. They also implement strict quality control measures, including regular testing of the tensile strength, flexibility, and uniformity of the fibers. Advanced manufacturing techniques, such as precision weaving and controlled resin application, are used to maintain consistency in the product. Additionally, environmental controls like temperature and humidity regulation are maintained to prevent variations in the material properties. Finally, post-production inspections and testing are conducted to verify that the final product meets all quality standards before it is released to the market.</p>

- Q: Is it possible to use black fiberglass tissue as a flooring material for a garden or patio?

- <p>Yes, you can use black fiberglass tissue to make flooring for your garden or patio. Fiberglass is known for its durability and resistance to weather, making it a suitable choice for outdoor applications. It's lightweight, easy to install, and can be used in combination with other materials like resin for a more solid and stable surface. However, it's important to ensure that the fiberglass is treated to be resistant to UV rays to prevent degradation over time. Always follow the manufacturer's guidelines for installation and maintenance to ensure the longevity and safety of your flooring.</p>

- Q: This question asks for guidance on selecting a dependable supplier for black fiberglass tissue, a material used in various industries.

- <p>To choose a reliable supplier of black fiberglass tissue, consider the following: Check their industry reputation and customer reviews. Ensure they have the necessary certifications and comply with industry standards. Evaluate their product quality by requesting samples. Assess their delivery times and reliability. Consider their customer service and after-sales support. Look for a supplier with a wide range of products to meet various needs. Finally, compare prices to ensure you're getting a fair deal without compromising on quality.</p>

- Q: Is it possible to utilize black fiberglass tissue to create insulation materials for residential buildings?

- <p>Yes, black fiberglass tissue can be used for making insulation materials for houses. Fiberglass, including its black variant, is a common material used in insulation due to its ability to resist heat transfer, providing thermal insulation. It is also known for its durability and resistance to moisture, which makes it suitable for various insulation applications in residential construction. However, it's important to note that proper handling and installation are necessary to ensure safety and effectiveness, as fiberglass can cause skin and respiratory irritation if not managed correctly.</p>

- Q: This question asks for a comparison of the cost of black fiberglass tissue with other fiberglass products.

- <p>The price of black fiberglass tissue can vary significantly compared to other types of fiberglass products due to factors such as quality, thickness, and market demand. Generally, it may be more expensive than standard white fiberglass due to its additional benefits like UV resistance and aesthetic appeal. However, prices can fluctuate based on the manufacturer, the specific product's properties, and the current market conditions. It's best to check with suppliers for the most accurate and up-to-date pricing information.</p>

- Q: What are the practical uses of black fiberglass tissue?

- <p>Black fiberglass tissue, also known as black glass fiber cloth, is widely used in various applications due to its heat resistance, electrical insulation, and mechanical strength. It is commonly used in electrical panels, high-temperature ovens, and heat insulation in industrial settings. Additionally, it is employed in the construction of soundproofing and thermal insulation materials. In the automotive industry, it is used for heat shields and as a component in brake linings. It also finds application in aerospace for heat-resistant components and in the manufacturing of certain types of filters due to its non-flammable nature.</p>

- Q: Is it possible to utilize black fiberglass tissue in the manufacturing of medical equipment?

- <p>Black fiberglass tissue is not typically used for medical equipment due to concerns about material safety, biocompatibility, and the potential for color-related issues in a medical context. Medical equipment often requires materials that are transparent or easily visible to ensure cleanliness and proper functioning. Additionally, materials used in medical applications must be non-toxic, resistant to corrosion, and able to withstand sterilization processes. While fiberglass can be used in some industrial applications, its use in medical equipment is limited and would require specific qualifications and approvals, focusing on white or clear forms that are more common in this industry.</p>

- Q: This question asks if there are any differences between various brands of black fiberglass tissue.

- <p>Yes, there can be differences between different brands of black fiberglass tissue. These differences may include the quality of the fibers, the thickness and uniformity of the tissue, the level of impurities, and the overall durability. Some brands may use higher quality raw materials or have more stringent manufacturing processes, resulting in a superior product. Additionally, the performance of the black fiberglass tissue can vary based on the specific application, such as in insulation, reinforcement, or acoustical purposes. It's important to consider the specific requirements of your project and choose a brand that meets those needs.</p>

- Q: This question asks about the distinctions between various grades of black fiberglass tissue, likely referring to the material properties and applications.

- <p>Different grades of black fiberglass tissue are distinguished by their weave patterns, thickness, tensile strength, and heat resistance. Grade E glass is the most common and offers a balance of strength and cost-effectiveness. Grade S glass is stronger and more durable, used for high-stress applications. Grade C glass is the strongest but also the most expensive, often used in aerospace and military applications. Each grade has specific uses based on the required properties for the end product, such as electrical insulation, reinforcement in composite materials, or high-temperature resistance.</p>

- Q: The user is asking if they can use old paper towels as a replacement for black fiberglass tissues in a situation where they don't have the latter available.

- <p>While it might be tempting to use old paper towels as a substitute for black fiberglass tissues, it is not recommended. Paper towels lack the strength and durability of fiberglass tissues, which are specifically designed for certain applications due to their heat resistance and insulation properties. Using paper towels could lead to ineffective insulation, potential fire hazards, or structural failure. It's best to use the appropriate materials as specified to ensure safety and effectiveness.</p>

Send your message to us

Fiberglass Facing Black Fiberglass Tissue for Glasswool-65EP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords