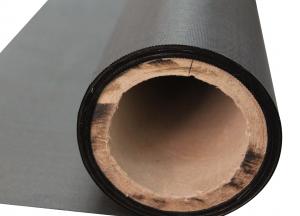

Fiberglass Facing Black Fiber Cloth BFC-160GSM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 100000M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Black Fiberglass Cloth BFC-001 (EW160F)

|

Specification | ||

|

ITEM |

UNIT |

VALUE |

|

Weight |

g/m2 |

160 |

|

Thickness |

mm |

0.2 |

|

Density |

/cm |

12×12 |

|

Oxygen Index Number |

% |

≥32 |

|

Tensile Strength MD |

n/5cm |

800 |

|

Tensile Strength CMD |

n/5cm |

500 |

|

Fire Resistant Property |

|

B1 |

MSDS:No harm for body and environment, non-volatile product.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: ±0.5%.

3. The products should be stored at room temperature, kept from wet and kept away heat source.

4. Good appearance without stain, oxidation, mildew.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

2. Application of Black Fiberglass Cloth BFC-001 (EW160F)

Fiberglass facing is good at fireproof, mildew resistant, damp proof and strong air permeability. After laminated with glass wool or rock wool, the physical properties is excellent such as hat preservation, noise elimination, fire retardant, extinction,etc.

3. Packaging & Delivery of Black Fiberglass Cloth BFC-001 (EW160F)

Depends on the clients' requirements and the production conditions.

- Q: This question asks for a comparison between black fiberglass tissue and other nonwoven materials, focusing on their characteristics and applications.

- <p>Black fiberglass tissue is a type of nonwoven material known for its high strength, durability, and resistance to heat and chemicals. Compared to other nonwoven materials such as polyester, polypropylene, and cellulose, black fiberglass tissue offers superior thermal insulation and sound absorption properties. It is often used in applications where these characteristics are crucial, such as in construction, automotive, and aerospace industries. While other nonwoven materials may be lighter or more cost-effective, black fiberglass tissue stands out for its ability to withstand harsh conditions and provide long-lasting performance.</p>

- Q: The user is asking if there are any health risks associated with regular use of black fiberglass tissue.

- <p>Regular use of black fiberglass tissue could potentially be harmful to your health. Fiberglass is made of fine glass fibers that can be inhaled or come into contact with skin, potentially causing irritation or more serious health issues. Prolonged exposure may lead to respiratory problems, skin irritation, and in some cases, more severe conditions like mesothelioma. It's advisable to handle fiberglass with care, using protective gear, and to limit exposure as much as possible. Always refer to the material safety data sheet (MSDS) for specific health and safety information regarding the product you're using.</p>

- Q: Is it permissible to use a personal brand of black fiberglass tissues for residential or commercial purposes?

- <p>Yes, you can use your own brand of black fiberglass tissues in your home or business. However, it's crucial to ensure that the product meets safety and quality standards. Check for certifications like ISO or ASTM to guarantee compliance with industry standards. Always follow the manufacturer's guidelines for installation and usage to maintain safety and effectiveness.</p>

- Q: Is it possible to use black fiberglass tissue as an insulating material within walls?

- <p>Yes, black fiberglass tissue can be used for insulation in walls. It is a type of fiberglass insulation that is often used in residential and commercial buildings due to its effectiveness in reducing heat transfer and providing thermal insulation. Black fiberglass tissue is made from glass fibers and has a high resistance to heat flow, which helps to maintain a comfortable temperature inside the building. It is also known for its durability and resistance to moisture, making it a popular choice for wall insulation. However, it's important to follow proper installation procedures and safety precautions to ensure the insulation's effectiveness and to protect against potential health risks associated with fiberglass.</p>

- Q: Is it possible to utilize black fiberglass tissue as an insulating material within vehicles?

- <p>Yes, black fiberglass tissue can be used for insulation in vehicles. It is known for its heat-resistant properties and is commonly used in automotive applications to insulate engine compartments and exhaust systems. Fiberglass provides thermal insulation, reduces noise, and protects against heat damage. However, it's important to ensure that the fiberglass used meets specific automotive standards for safety and performance.</p>

- Q: This question asks for the distinguishing characteristics of black fiberglass tissue compared to other fiberglass products.

- <p>Black fiberglass tissue is a specific type of fiberglass product that is treated with a black pigment to provide UV resistance and aesthetic appeal. It is often used in applications where a black finish is desired or where it's exposed to sunlight for extended periods. In contrast, other fiberglass products may come in various colors or be clear, and they can be used for a wider range of applications, including insulation, reinforcement in composite materials, and electrical applications. The main difference lies in the appearance and specific performance attributes, such as UV protection, which is enhanced in black fiberglass tissue due to the pigmentation.</p>

- Q: Is it possible to utilize glass fiber paper as an insulating material within air conditioning systems?

- <p>Yes, glass fiber paper can be used for insulation in air conditioning systems. It is known for its high heat resistance, good thermal insulation properties, and resistance to moisture, making it suitable for maintaining the efficiency of air conditioning systems by reducing heat transfer. However, it's important to ensure that the glass fiber paper used meets the specific requirements for air conditioning applications, such as being non-flammable and resistant to the chemicals and conditions present in these systems.</p>

- Q: Is it possible to utilize black fiberglass tissues for domestic cleaning purposes?

- <p>Black fiberglass tissues are not typically recommended for household cleaning tasks. Fiberglass, especially when in a loose or frayed state, can be abrasive and may scratch surfaces. It can also leave behind fibers that are difficult to remove. For cleaning, it's better to use materials specifically designed for the purpose, such as microfiber cloths, which are gentle on surfaces and effective at picking up dirt and dust without scratching.</p>

- Q: Is it possible to utilize black fiberglass tissue as an insulating material in construction?

- <p>Yes, black fiberglass tissue can be used for building insulation. It is a type of insulation material known for its thermal and acoustic insulation properties. Black fiberglass is made from glass fibers and is often used in construction for insulating walls, roofs, and floors. It helps to reduce heat transfer, thereby improving energy efficiency and comfort within the building. However, it's important to note that proper installation and safety precautions are necessary due to the potential health risks associated with fiberglass, such as skin and respiratory irritation.</p>

- Q: Can black fiberglass tissue be utilized effectively as a material for filters?

- <p>Yes, black fiberglass tissue can be used as a filter material. It is known for its high tensile strength and resistance to chemicals, making it suitable for air and liquid filtration applications. However, it's important to note that fiberglass may not be suitable for all types of filtration due to potential health risks associated with inhalation of fibers and the need for specific conditions to prevent degradation. It is often used in industrial settings for filtering particulates and in HVAC systems. Always ensure that the use of fiberglass tissue complies with safety standards and the specific requirements of the filtration task at hand.</p>

1. Manufacturer Overview

| Location | Jangsu, China |

| Year Established | 1999 |

| Annual Output Value | Above US$0.3 billion |

| Main Markets | 0.00% Mid East 15.00% Northern Europe 15.00% North America 10.00% Eastern Asia 20.00% Africa 0.00% Eastern Europe 20.00% Southeast Asia 0.00% Oceania 0.00% Western Europe 0.00% Southern Europe 0South east asia;North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Facing Black Fiber Cloth BFC-160GSM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 100000M2 Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords