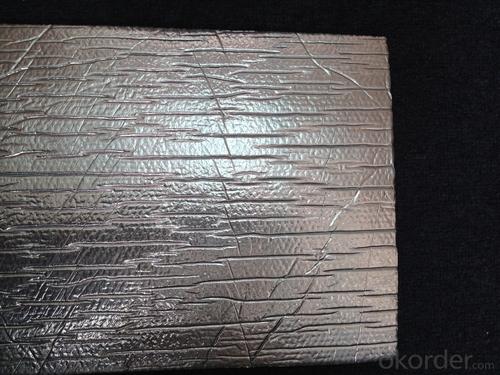

Fiberglass Facing Flexible Ducts Bubble Insulation Green Energy

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: This question asks about the methods used by manufacturers to maintain the quality of black fiberglass tissue during the manufacturing process.

- <p>Manufacturers ensure the quality of black fiberglass tissue during production through several key steps. They start with high-quality raw materials, such as virgin glass fibers and resins, to ensure strength and durability. They also implement strict quality control measures, including regular testing of the tensile strength, flexibility, and uniformity of the fibers. Advanced manufacturing techniques, such as precision weaving and controlled resin application, are used to maintain consistency in the product. Additionally, environmental controls like temperature and humidity regulation are maintained to prevent variations in the material properties. Finally, post-production inspections and testing are conducted to verify that the final product meets all quality standards before it is released to the market.</p>

- Q: What is the texture or appearance of the surface of black fiberglass tissue?

- <p>The surface finish of black fiberglass tissue is typically smooth and matte. It is characterized by a uniform, non-reflective appearance with a slight texture that is often associated with the woven nature of the fiberglass. This finish can vary slightly depending on the specific manufacturing process and the intended application of the fiberglass tissue.</p>

- Q: What are the benefits of using fiberglass facing?

- There are several benefits of using fiberglass facing in various applications. Firstly, fiberglass facing offers excellent strength and durability, making it highly resistant to cracking, warping, and other forms of damage. This makes it ideal for use in construction and structural applications where strength and longevity are important factors. Additionally, fiberglass facing provides excellent thermal insulation properties. It has a low thermal conductivity, meaning it can effectively prevent heat transfer and maintain a consistent temperature in both hot and cold environments. This makes it a popular choice for insulation in buildings, HVAC systems, and other applications where energy efficiency is a key consideration. Another advantage of fiberglass facing is its resistance to moisture and corrosion. It is non-porous and does not absorb water, making it highly resistant to mold, mildew, and rot. This makes it a suitable material for use in damp or humid environments, such as bathrooms and kitchens. Furthermore, fiberglass facing is lightweight and easy to handle, making it convenient to install and transport. It can be easily cut and shaped to fit various surfaces and configurations, allowing for flexibility in design and installation. Its lightweight nature also reduces the strain on supporting structures, making it a cost-effective choice for construction projects. Lastly, fiberglass facing is available in a wide range of sizes, thicknesses, and finishes, allowing for customization to meet specific project requirements. It can be coated or laminated with different materials to enhance its performance, such as adding a vapor barrier or reflective surface. This versatility makes it suitable for a variety of applications in industries ranging from construction to transportation. In summary, the benefits of using fiberglass facing include its strength and durability, thermal insulation properties, resistance to moisture and corrosion, lightweight nature, and customization options. These advantages make it a popular choice in various industries where these characteristics are valued.

- Q: The user is asking if they can use old dryer sheets with black fiberglass tissues to enhance their performance.

- <p>Using old dryer sheets with black fiberglass tissues is not recommended as it may not improve their performance and could potentially cause damage. Dryer sheets are designed to reduce static and soften fabrics in laundry, and their chemicals may not be suitable for fiberglass tissues. Instead, consider using products specifically designed for cleaning and maintaining fiberglass to ensure their longevity and optimal performance.</p>

- Q: Is it possible to utilize black fiberglass tissue as a flooring material in high-rise constructions?

- <p>Yes, black fiberglass tissue can be used for flooring in high-rise buildings. It is known for its high strength, durability, and resistance to various environmental factors. Fiberglass tissue is often used in composite materials and can be combined with other materials to create a strong and stable flooring solution. However, it's crucial to ensure that the specific type of fiberglass tissue meets the necessary safety standards and building codes for high-rise construction, as well as to consider its fire resistance and load-bearing capabilities.</p>

- Q: This question asks for a comparison between domestic and imported black fiberglass tissue, highlighting their differences.

- <p>The differences between domestic and imported black fiberglass tissue can be attributed to several factors. Domestic black fiberglass tissue is often more affordable due to lower production costs and is readily available in the local market. It may also be more tailored to local standards and requirements. Imported black fiberglass tissue, on the other hand, is usually of higher quality and may offer advanced features not found in domestic versions. It is often sourced from countries with advanced manufacturing capabilities and stringent quality control processes. However, it comes with higher costs due to import taxes and shipping fees. Additionally, imported products may have longer lead times for delivery. Both types have their advantages and disadvantages, and the choice between them depends on specific project requirements, budget, and quality expectations.</p>

- Q: Is it possible to utilize black fiberglass tissue as a material for filtration purposes?

- <p>Yes, black fiberglass tissue can be used as a filtration media. It is known for its high tensile strength and resistance to chemicals, making it suitable for various filtration applications. Black fiberglass tissue is often used in air and liquid filtration systems due to its ability to withstand high temperatures and resist corrosion. However, it's important to consider the specific requirements of the filtration system, such as temperature and chemical compatibility, to ensure the black fiberglass tissue is the appropriate choice.</p>

- Q: Is it possible to utilize black fiberglass tissue for creating wall paneling?

- <p>Yes, you can use black fiberglass tissue to make wall paneling. Fiberglass is known for its strength, durability, and resistance to moisture and corrosion, making it suitable for wall paneling. It can be molded into various shapes and sizes, and its black color can add a modern aesthetic to your walls. However, it's important to ensure proper installation and adherence to safety guidelines, as fiberglass can cause skin and respiratory irritation if not handled correctly. Always wear protective gear and follow manufacturer's instructions.</p>

- Q: Is there a specific kind of black fiberglass tissue that is safe and appropriate for use by infants and young children?

- <p>There isn't a specific type of black fiberglass tissue designed for babies and young children. Fiberglass tissues are not recommended for use on children's skin due to the potential for skin irritation and respiratory issues. Instead, for babies and young children, it's best to use soft, hypoallergenic tissues that are gentle on the skin. Always check the product labels for safety and suitability for children.</p>

- Q: Can the black fiberglass material be processed and reused in a recycling context?

- <p>Yes, black fiberglass tissue can be recycled, although the process is more complex than recycling other materials due to its composite nature. Fiberglass, made of glass fibers reinforced by a plastic matrix, requires specialized facilities to separate and recycle. The black color is often due to the use of carbon or other pigments, which do not affect recyclability. Recyclers may grind the material into a fine powder or chopped strand to be used as filler in new composite products, or it may be used in construction materials. However, the market for recycled fiberglass is limited, and not all recycling facilities accept it. Proper recycling depends on collection systems and the availability of recycling plants equipped to handle fiberglass.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Insulation Green Energy

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords