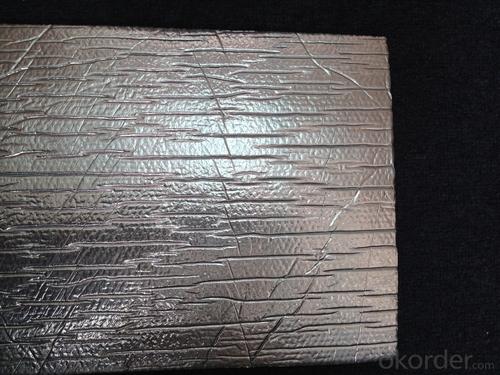

Fiberglass Facing Flexible Ducts Bubble Glasswool Green Energy

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: The user is asking if there are any health risks associated with regular use of black fiberglass tissue.

- <p>Regular use of black fiberglass tissue could potentially be harmful to your health. Fiberglass is made of fine glass fibers that can be inhaled or come into contact with skin, potentially causing irritation or more serious health issues. Prolonged exposure may lead to respiratory problems, skin irritation, and in some cases, more severe conditions like mesothelioma. It's advisable to handle fiberglass with care, using protective gear, and to limit exposure as much as possible. Always refer to the material safety data sheet (MSDS) for specific health and safety information regarding the product you're using.</p>

- Q: What is the lifespan or strength of black fiberglass tissue?

- <p>The durability of black fiberglass tissue is quite high due to its resistance to various environmental factors. It is known for its strength, corrosion resistance, and ability to withstand high temperatures. Depending on the specific application and environmental conditions, the lifespan can vary. However, under normal circumstances, black fiberglass tissue can last for several years without significant degradation, making it a popular choice for applications requiring long-term durability and low maintenance.</p>

- Q: This question asks for the most effective method to clean black fiberglass material.

- <p>The best way to clean black fiberglass tissue is by using a gentle cleaning solution and soft bristled brush. Start by mixing a mild detergent with warm water. Apply the solution to the fiberglass and gently scrub with a soft brush to avoid scratching. Rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. For stubborn stains, consider using a fiberglass-specific cleaning product, but always test on a small area first to ensure it doesn't discolor the material. Regular cleaning will help maintain the appearance and longevity of black fiberglass tissue.</p>

- Q: This question asks for a comparison between domestic and imported black fiberglass tissue, highlighting their differences.

- <p>The differences between domestic and imported black fiberglass tissue can be attributed to several factors. Domestic black fiberglass tissue is often more affordable due to lower production costs and is readily available in the local market. It may also be more tailored to local standards and requirements. Imported black fiberglass tissue, on the other hand, is usually of higher quality and may offer advanced features not found in domestic versions. It is often sourced from countries with advanced manufacturing capabilities and stringent quality control processes. However, it comes with higher costs due to import taxes and shipping fees. Additionally, imported products may have longer lead times for delivery. Both types have their advantages and disadvantages, and the choice between them depends on specific project requirements, budget, and quality expectations.</p>

- Q: Is it possible to use black fiberglass tissue in outdoor environments?

- <p>Yes, black fiberglass tissue can be used for outdoor applications. It is known for its strength, durability, and resistance to weather conditions. However, it's important to ensure that the fiberglass is treated with UV stabilizers to protect it from the harmful effects of ultraviolet radiation, which can degrade the material over time. Additionally, it should be properly sealed or coated to prevent moisture absorption, which can lead to degradation. When these precautions are taken, black fiberglass tissue can be a reliable material for various outdoor uses.</p>

- Q: Is it possible to utilize black fiberglass tissue within the interior of a car?

- <p>Yes, black fiberglass tissue can be used in car interiors. It is known for its strength, durability, and lightweight properties, making it suitable for various interior applications such as decorative panels, structural components, and even certain types of trim. However, it's important to ensure that the material meets safety standards and is properly treated for any potential health concerns related to fiber exposure.</p>

- Q: Is it possible to utilize black fiberglass tissue for soundproofing purposes?

- <p>Yes, black fiberglass tissue can be used for acoustic insulation. It is a popular material in construction and home improvement due to its ability to absorb sound waves, reducing noise transmission. The fibers in the tissue create a porous structure that traps sound energy, converting it into heat and diminishing its intensity. This makes it effective in soundproofing walls, ceilings, and floors, particularly in areas where noise reduction is crucial, such as recording studios, theaters, or noisy industrial environments. However, it's important to handle fiberglass with care due to its potential health risks, and to ensure proper installation to maximize its acoustic insulation properties.</p>

- Q: Is it possible to enhance the aesthetic appeal of furniture using black glass fiber paper?

- <p>Yes, black glass fiber paper can be used to make furniture more attractive. It offers a sleek, modern look and can be applied to surfaces for a unique texture and finish. Used in combination with other materials or colors, it can create a striking contrast, enhancing the visual appeal. However, it's important to consider the durability and practicality of using such materials in furniture making, as well as the overall design to ensure it complements the intended aesthetic.</p>

- Q: Is it possible to utilize black fiberglass tissue in residential settings?

- <p>Yes, black fiberglass tissue can be used in residential applications. It is commonly utilized for insulation purposes, providing thermal and acoustic insulation. Black fiberglass is also used in the construction of walls, ceilings, and roofs to enhance energy efficiency and reduce noise pollution. However, it's important to ensure that it is installed correctly and safely, as improper handling can lead to health issues due to the potential release of fiberglass fibers.</p>

- Q: What are the uses of black fiberglass tissue in the construction industry?

- <p>Black fiberglass tissue, also known as black glass fiber cloth, is widely used in construction for its heat resistance, strength, and durability. It is commonly used as a reinforcement material in cementitious materials, such as in the production of GRC (Glass Reinforced Concrete) panels and other composite materials. It can also be used as a fire-resistant barrier in walls and ceilings, and for insulation purposes. Additionally, it is employed in the creation of lightweight and strong structures, such as in the construction of roofs and facades, due to its high tensile strength and low weight.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Glasswool Green Energy

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords